ASLI | Across International Market ● Expand International Business Professional Brand of Ventilation Fittings

Headquarters Laboratory

Motivation for building a ventilation and noise laboratory

1. Verify the airflow distribution of the vents and provide correct performance data

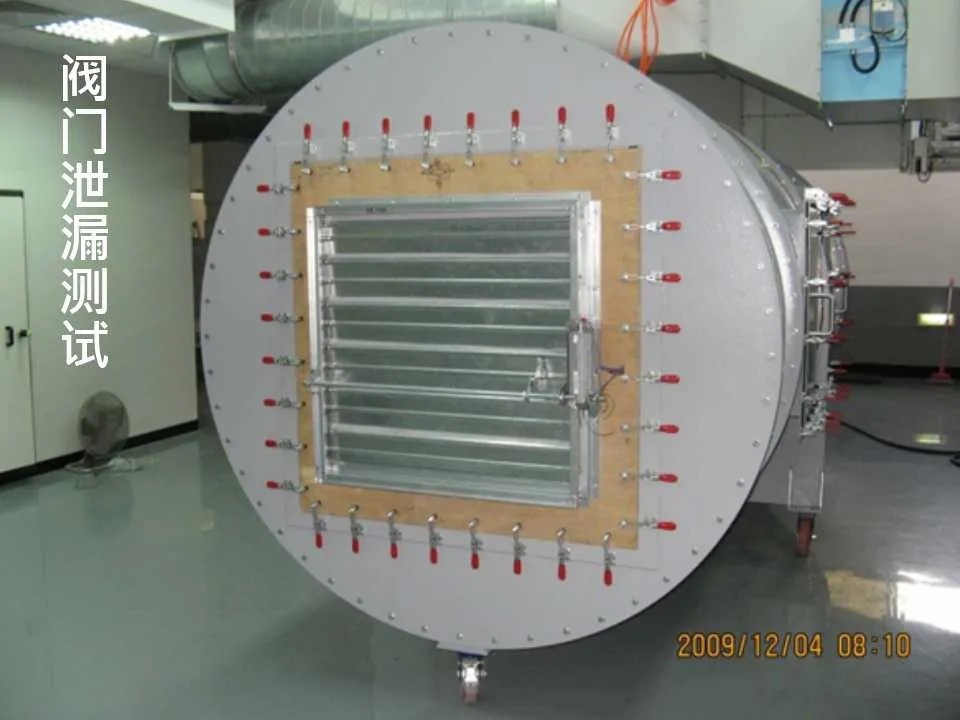

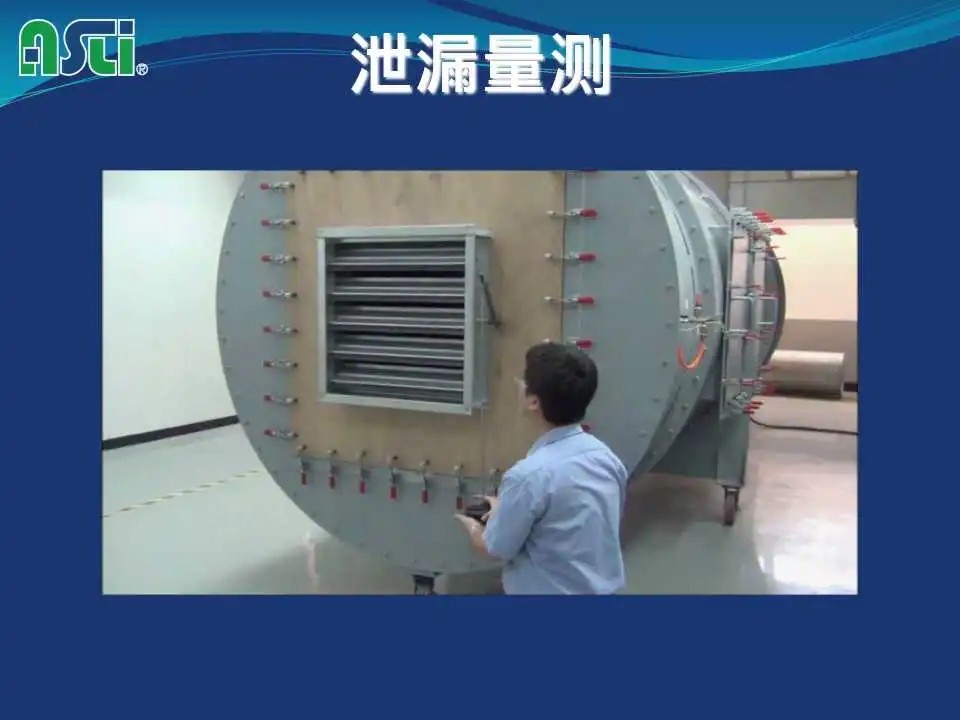

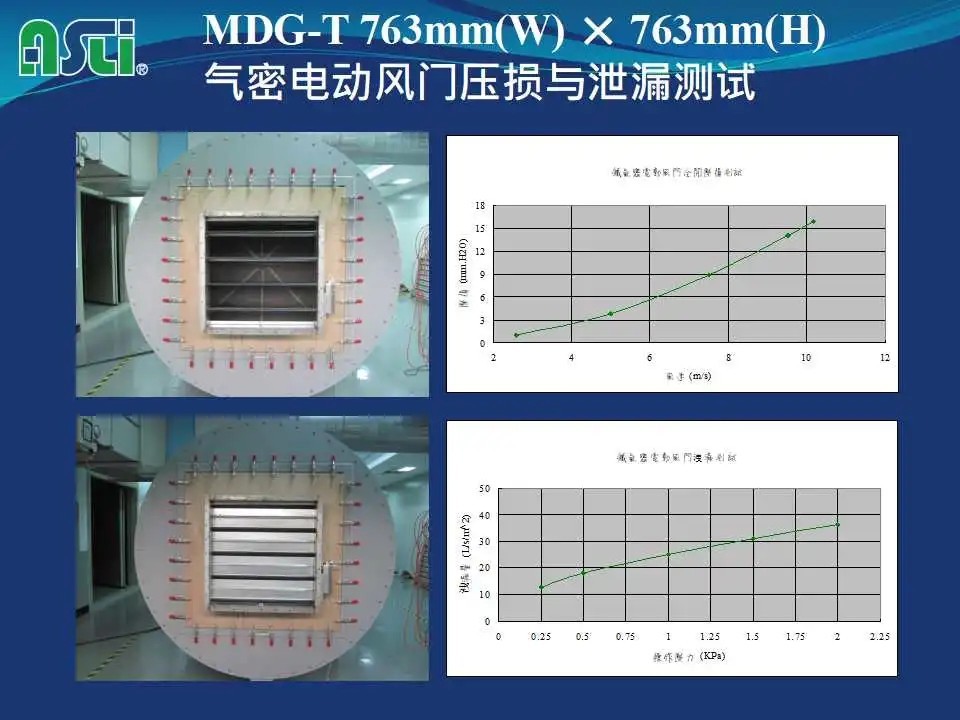

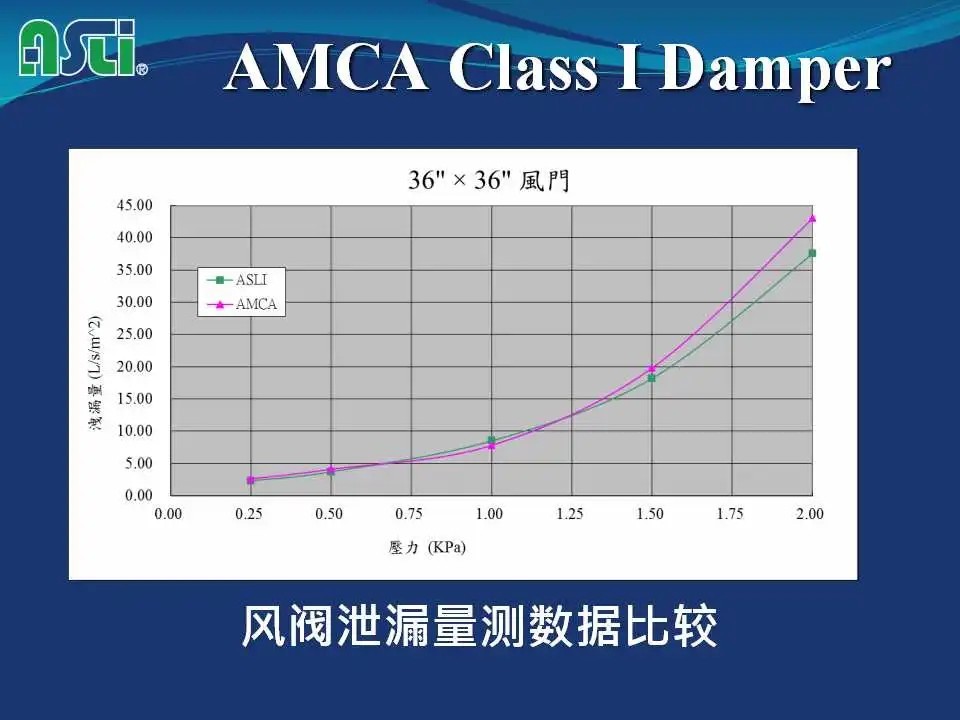

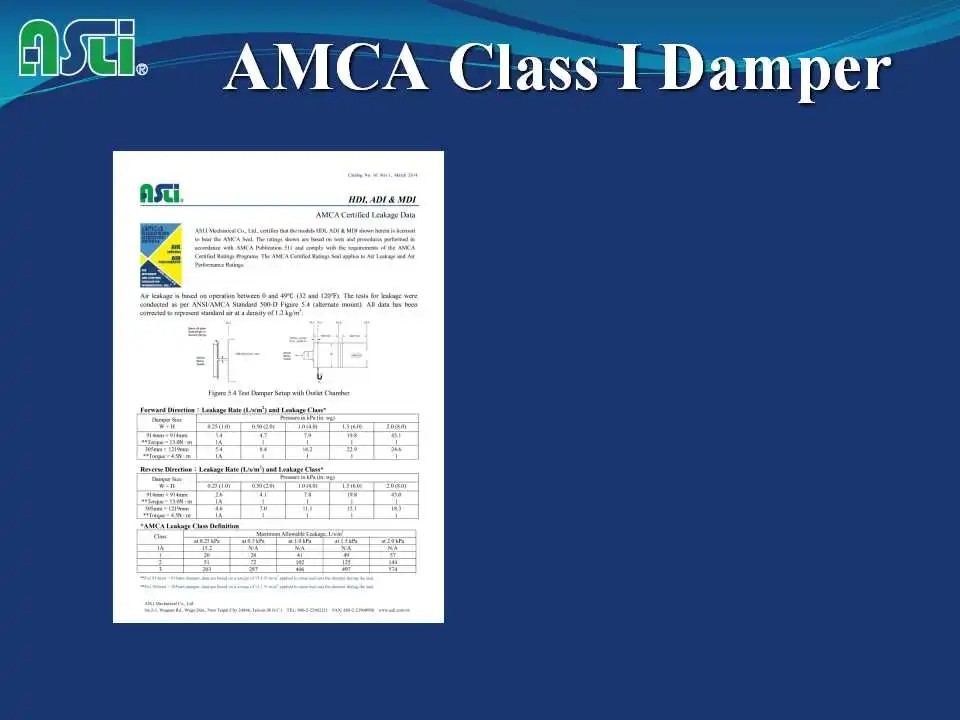

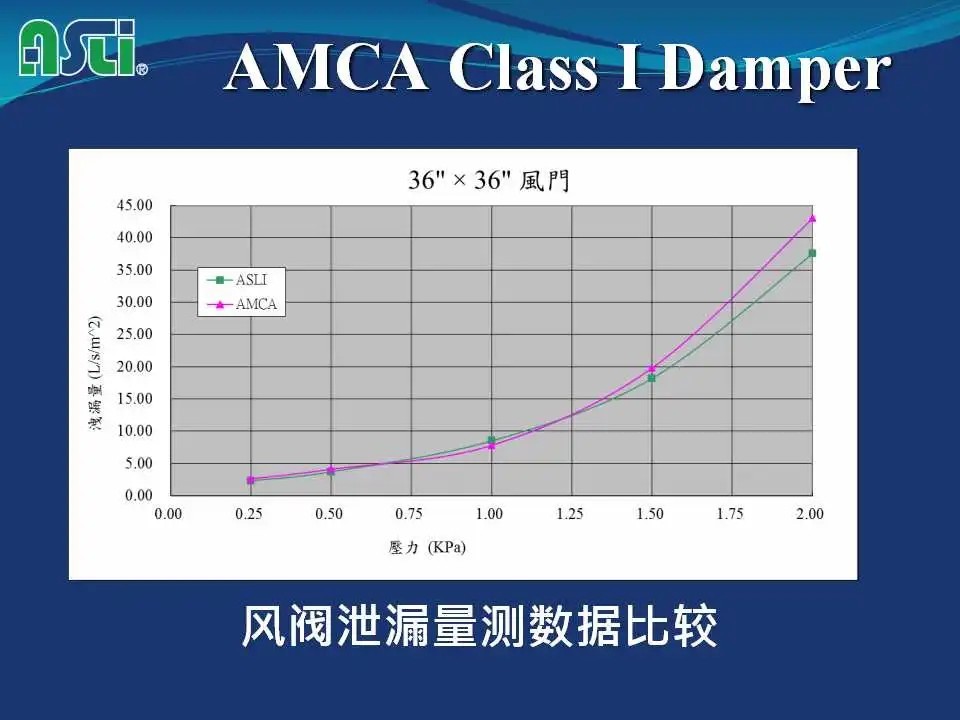

2. Test the level of valve leakage to improve product competitiveness with world-class manufacturers

3. Overcome the difficulties in obtaining UL certification and increase the speed of fire damper performance verification

4. Provide noise product performance to improve the noise quality environment

5. Improve the product quality and corporate image of the group company

Laboratory Introduction

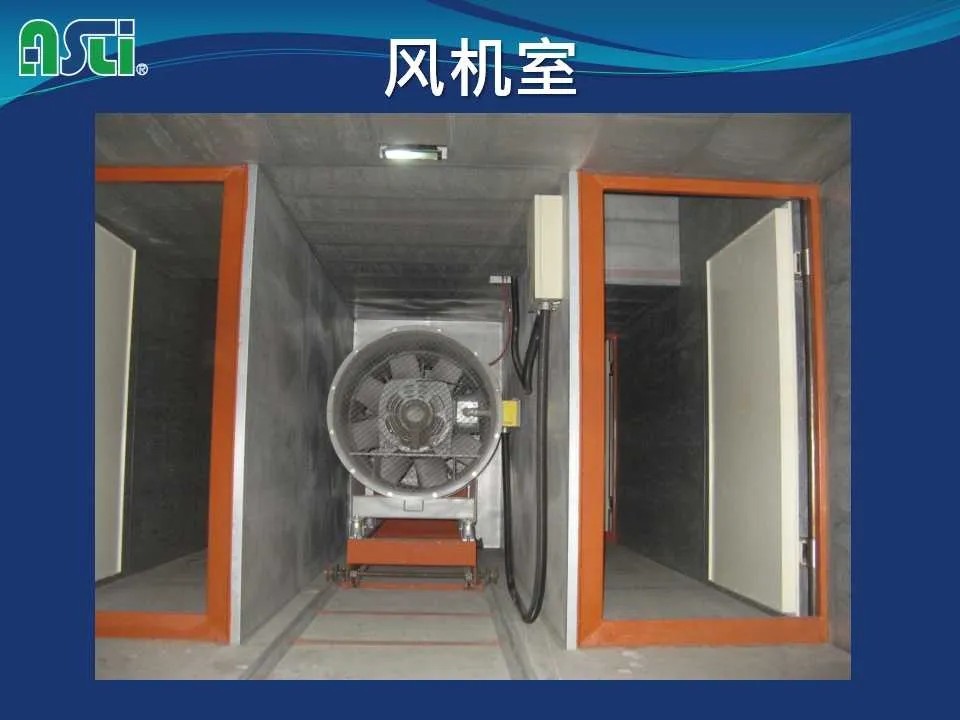

● The laboratory is located in Taoyuan, Taiwan, with a usable area of 2,600 square meters.

● In line with the market requirements of Taiwan and Southeast Asia, the measuring equipment

is designed and constructed in accordance with the test standards of ISO, AMCA, UL, ASTM and ASHRAE.

● Product performance verification test procedures and equipment and instruments all comply with relevant international test standards.

● Laboratory certification

A. Taiwan TAF Certification Foundation Certified Laboratory (SO 17025), certification number 2385. (TAF is equivalent to China CNAS)

B. US UL Certified Laboratory (UL 555/555S)

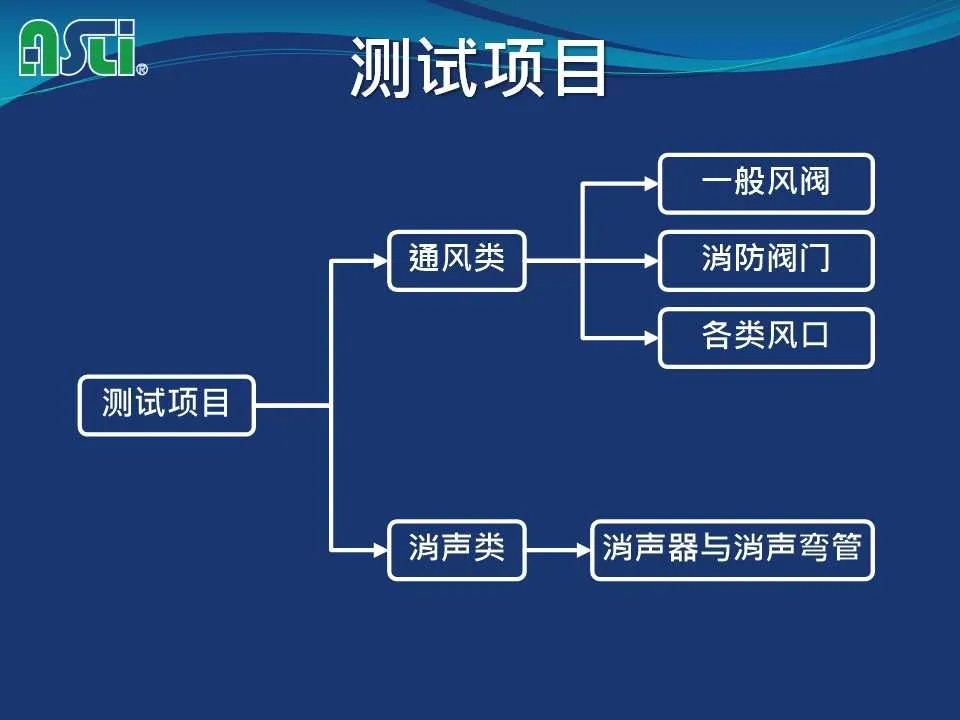

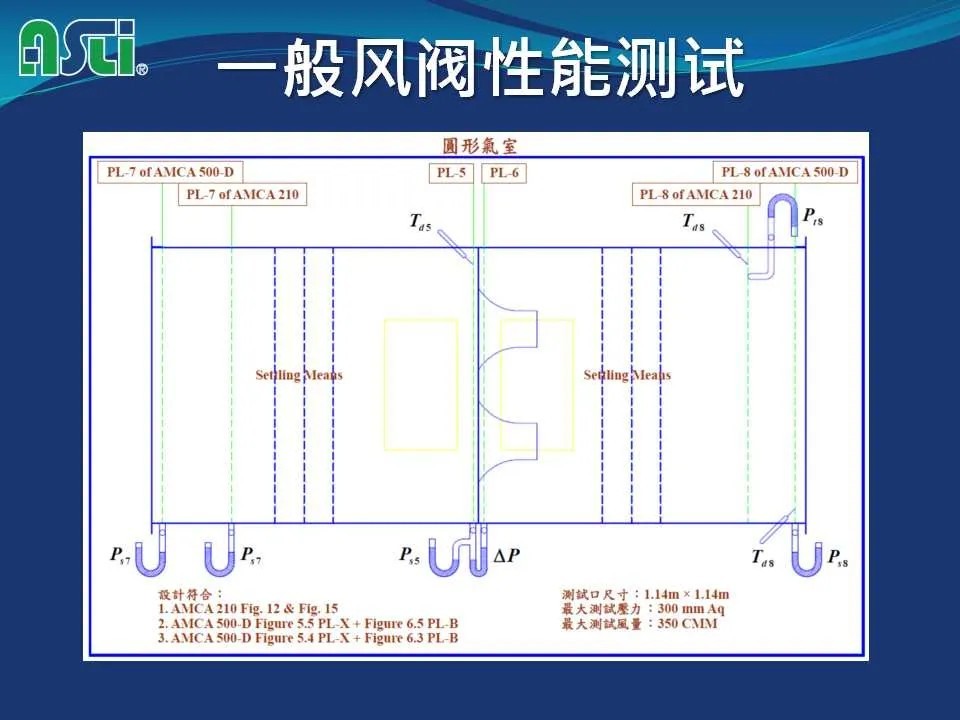

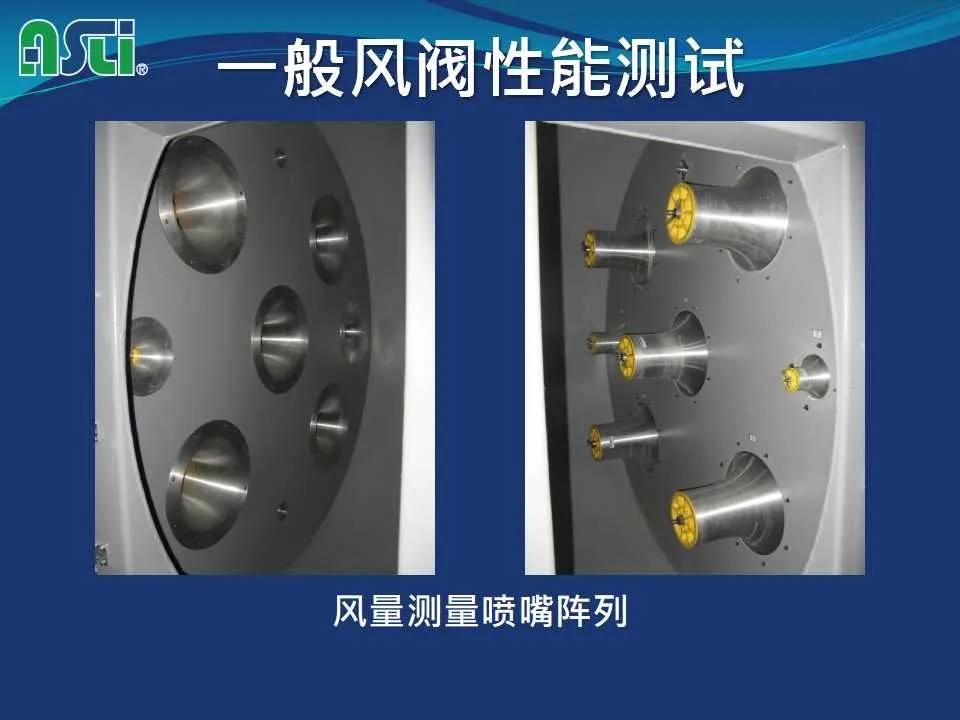

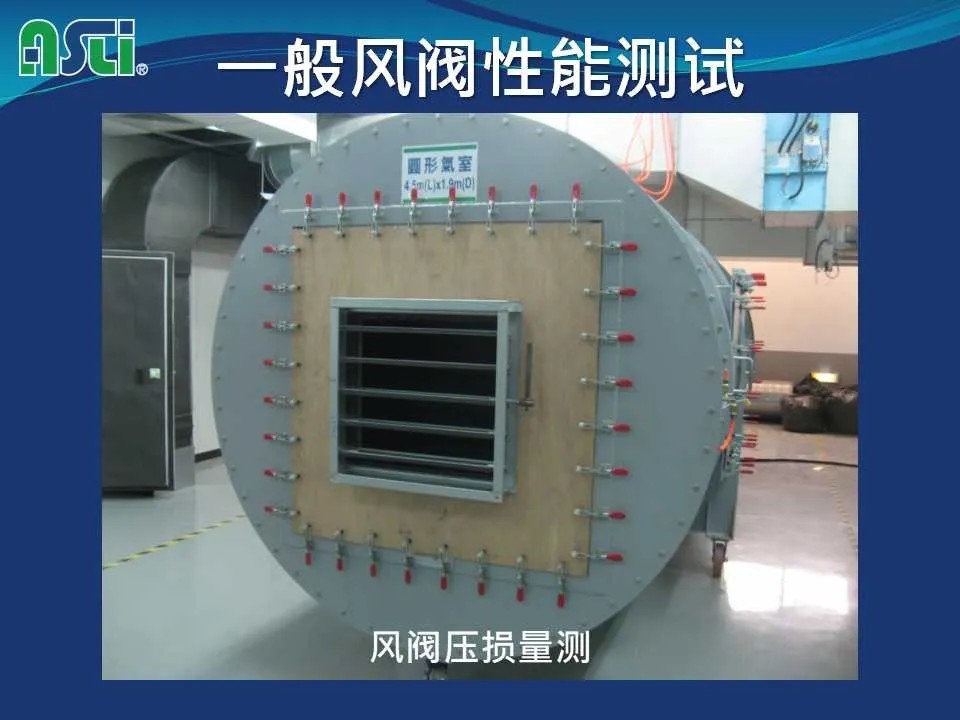

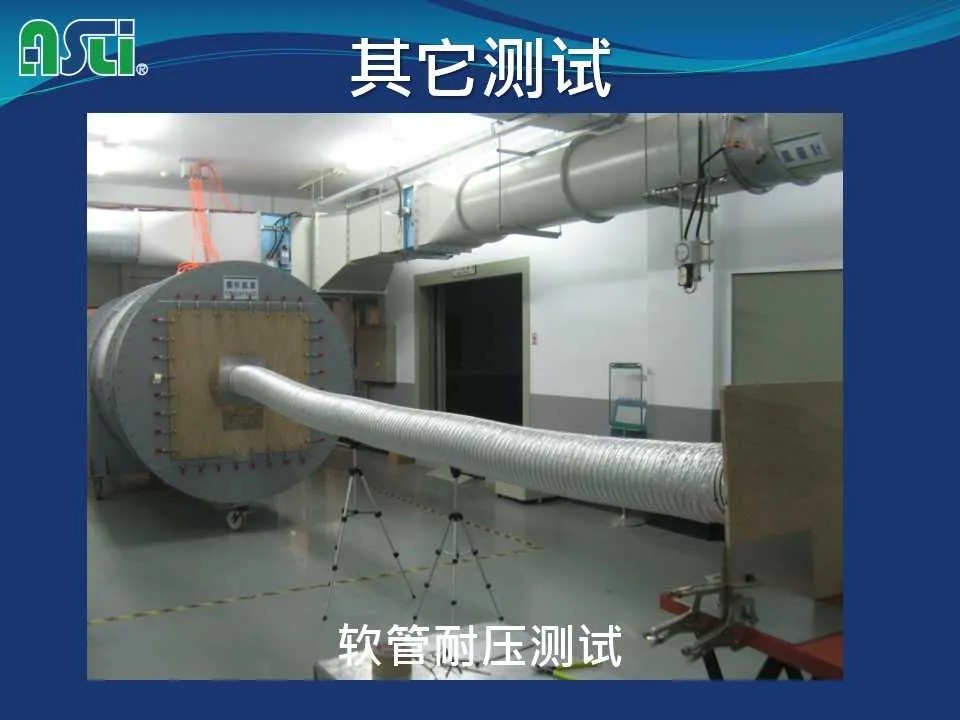

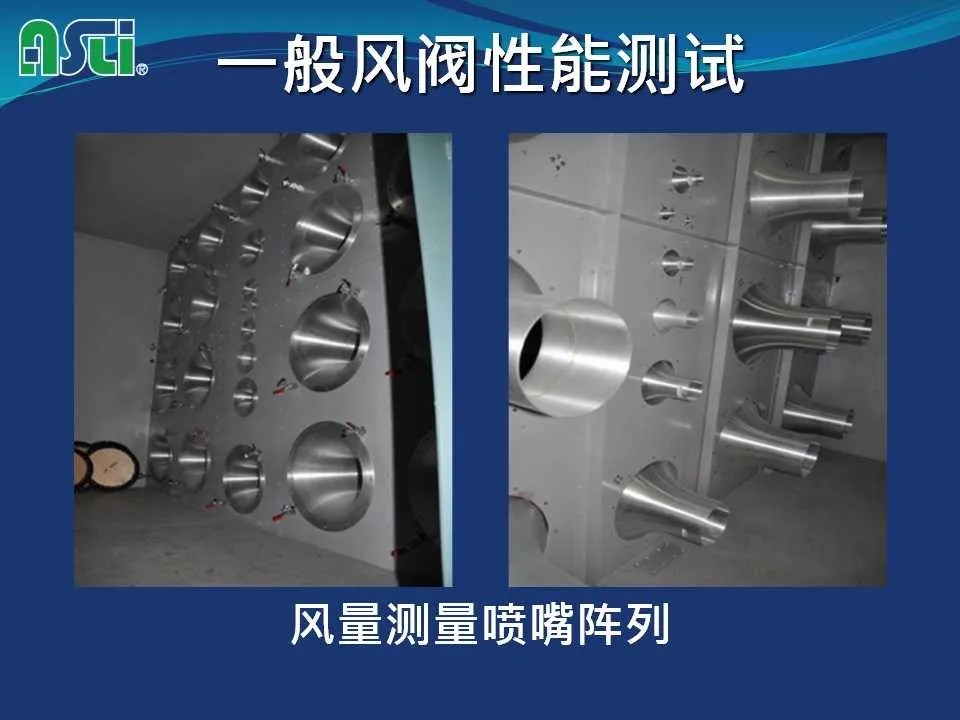

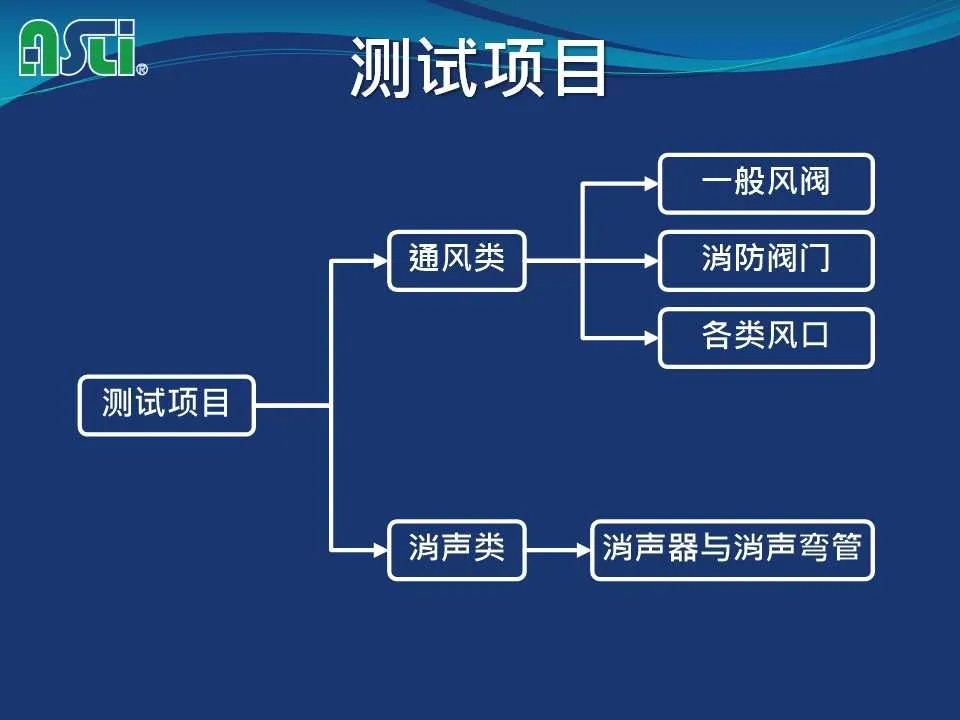

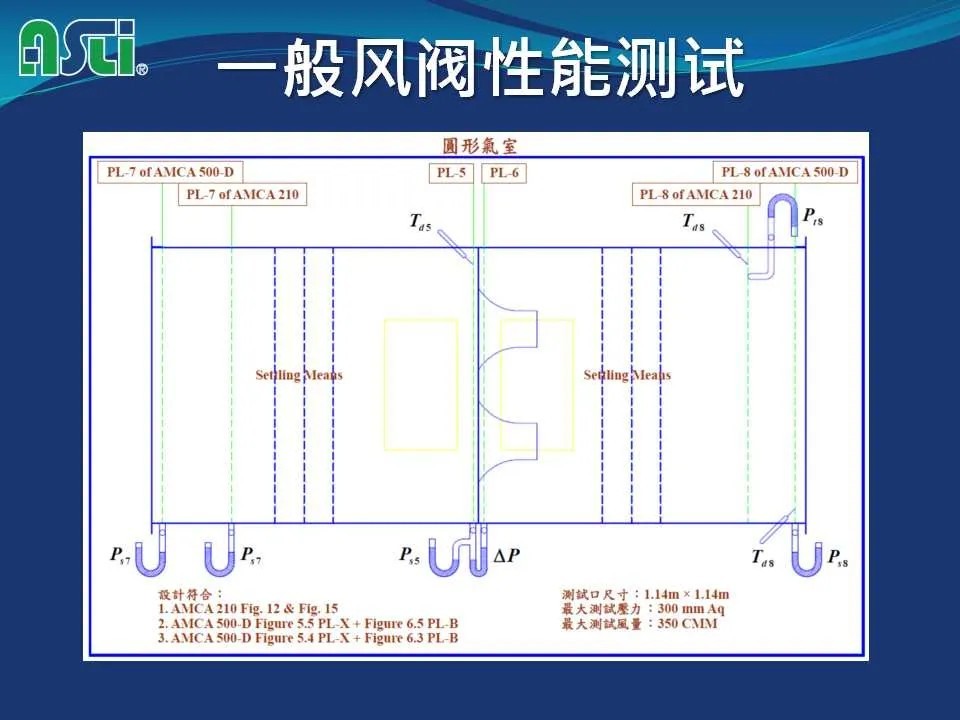

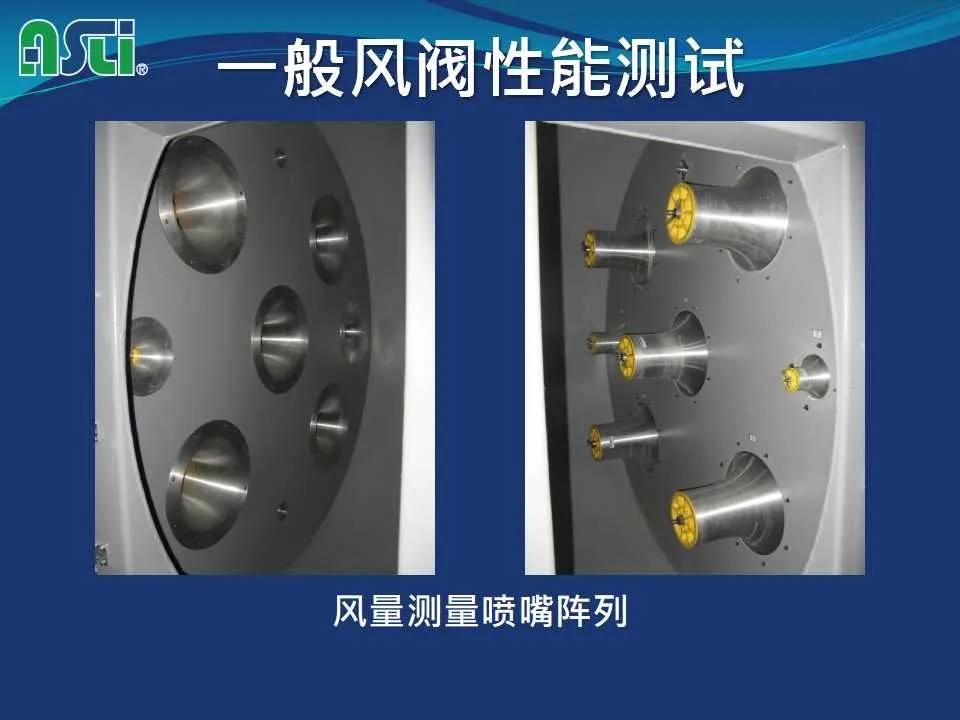

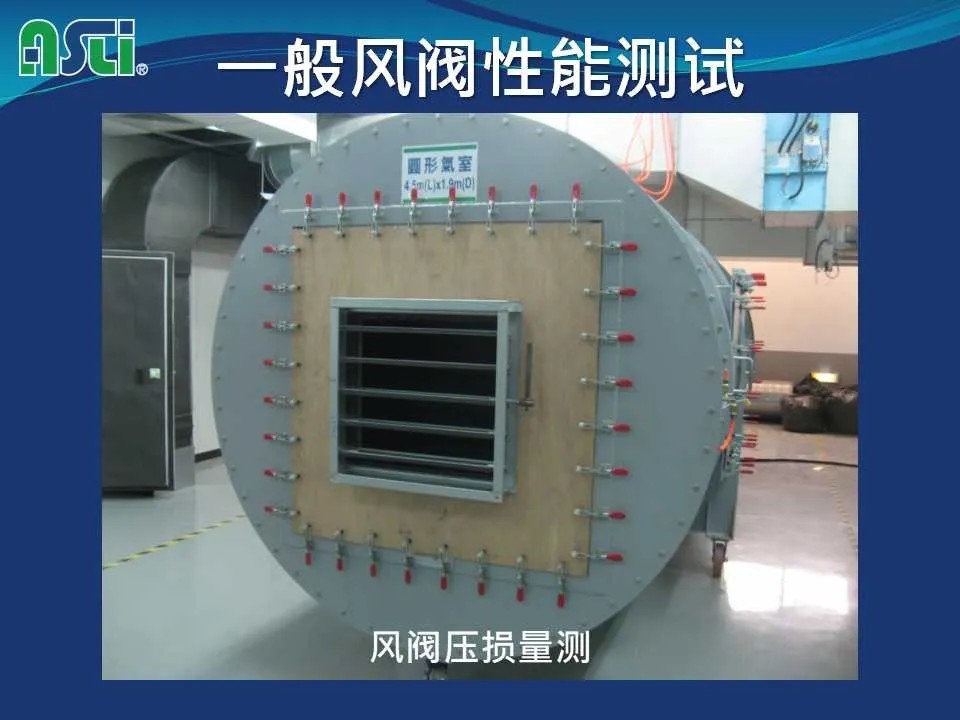

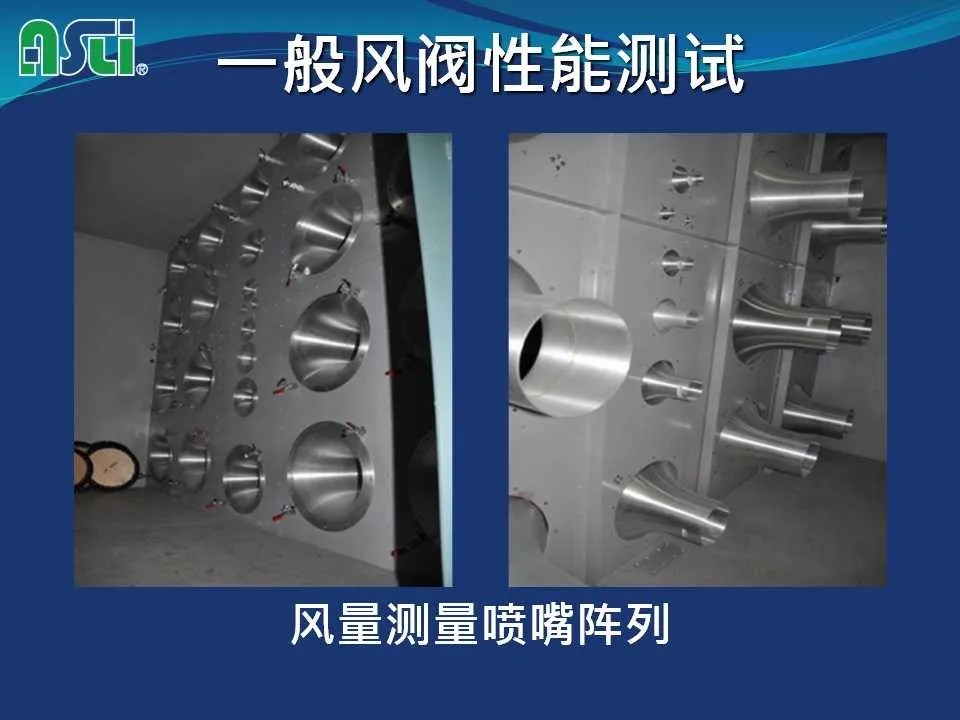

General air valve performance test

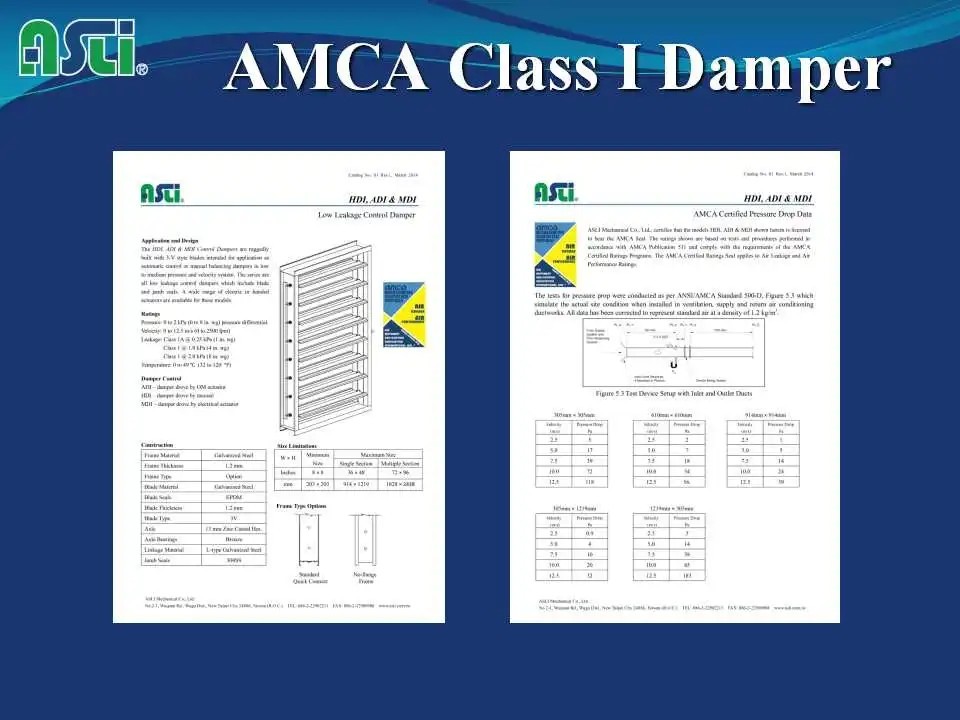

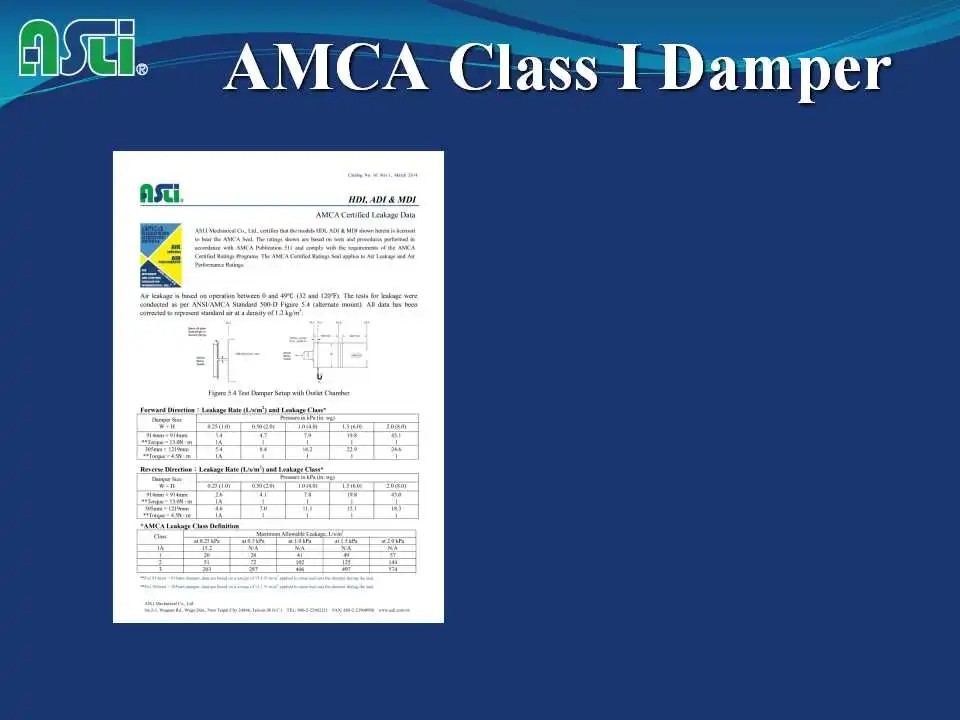

● Method basis: AMCA 500-D

● Equipment capabilities:

1. Circular air chamber

test port size - 1.14m Φ 1.14m

Maximum test pressure - 300mmAq

Maximum test air volume - 350CMM

2. Rectangular air chamber

test port size - 2.0m Φ 2.0m

Maximum test pressure - 340mmAq

Maximum test air volume - 2800CMM

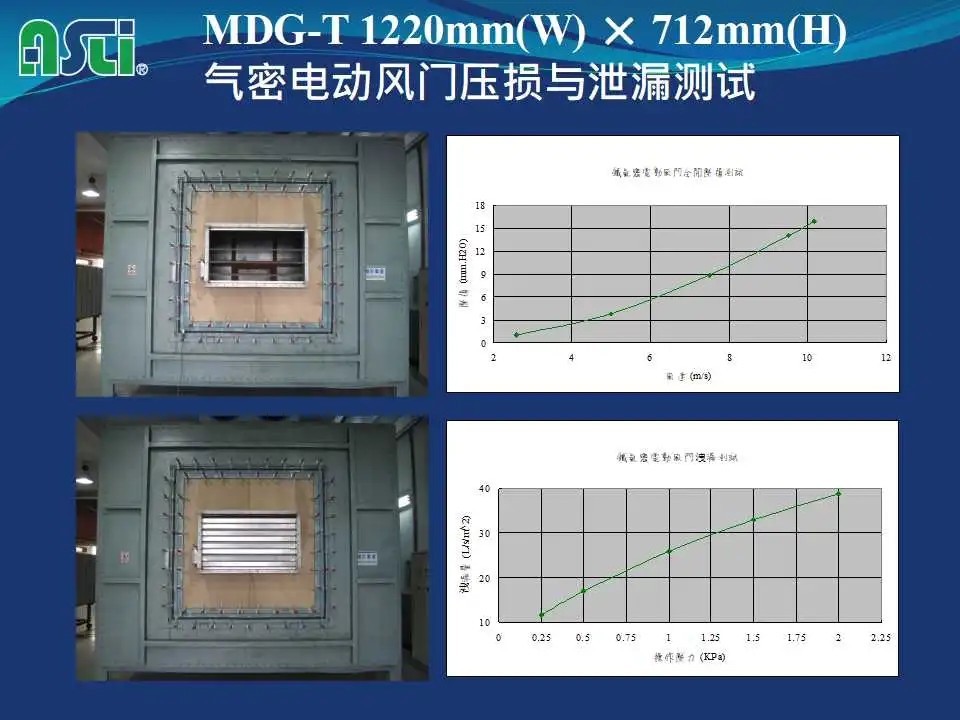

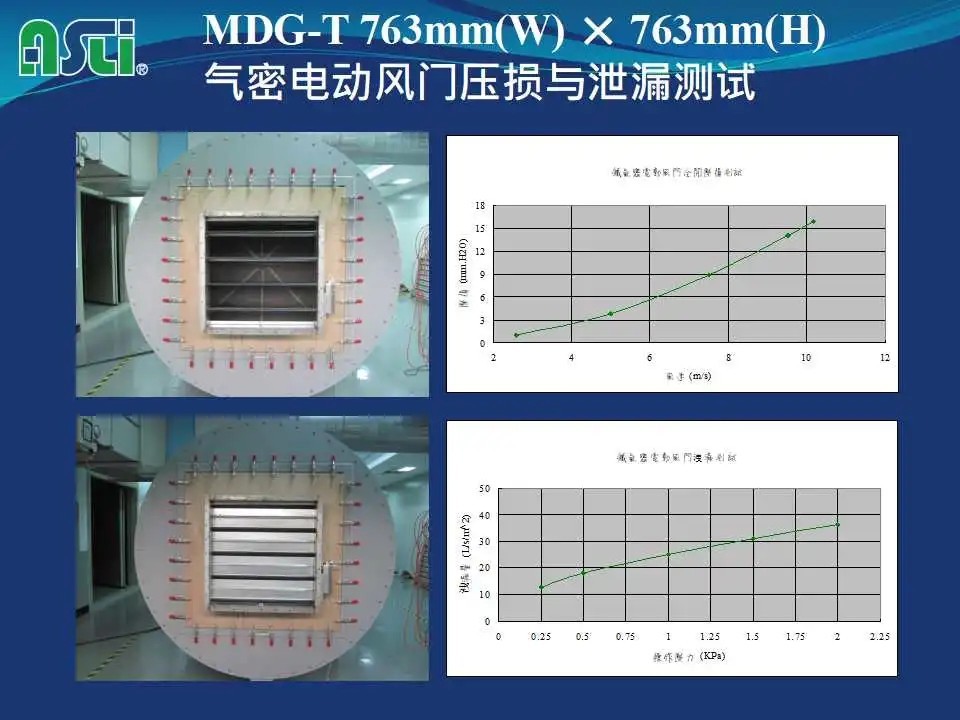

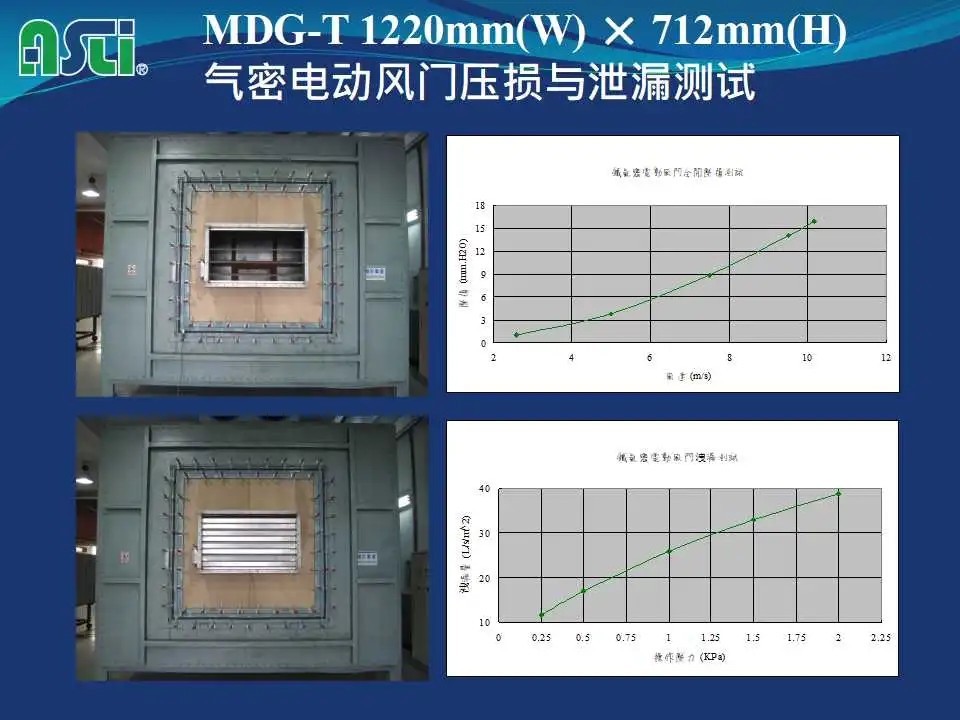

● Measurement items: pressure loss, leakage and pressure resistance

Future work - Introducing national standard testing methods to meet the needs of the Chinese market

JG/T 436 Building ventilation air volume regulating valve

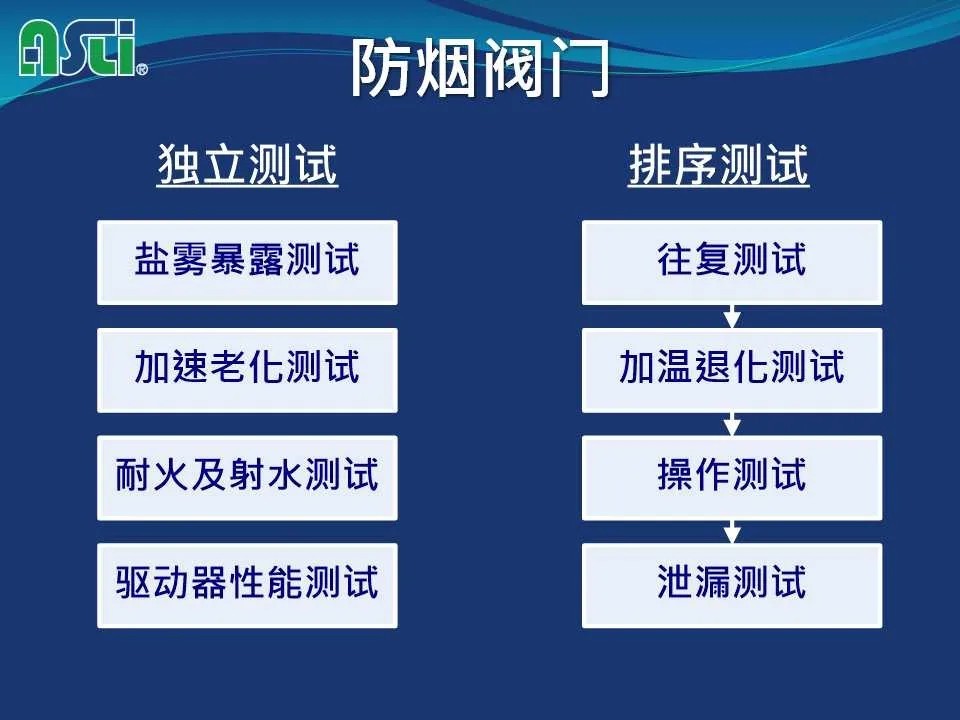

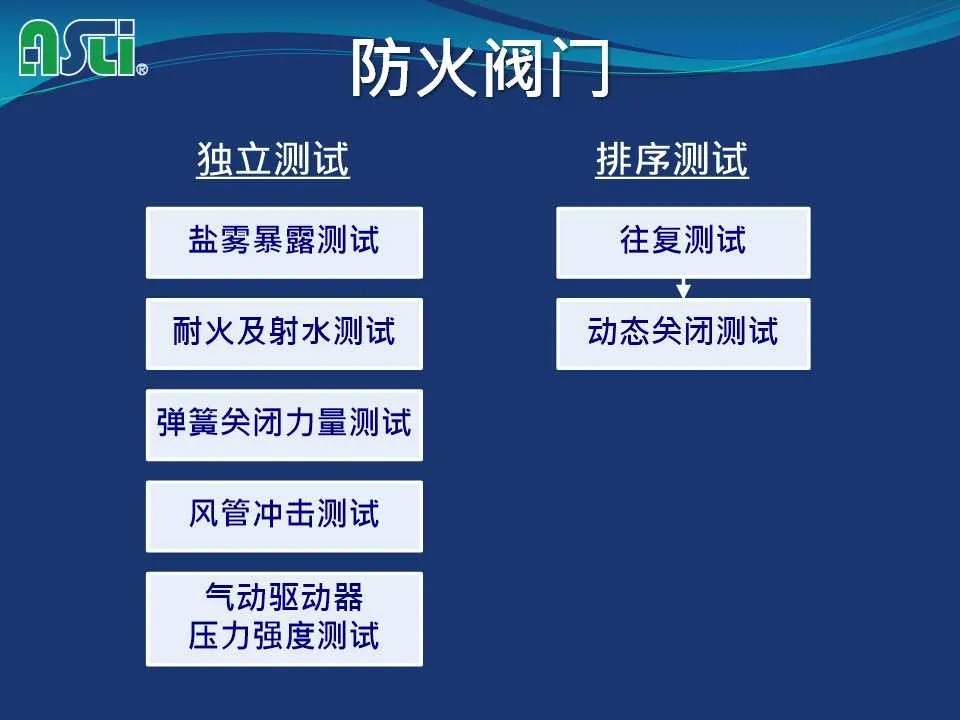

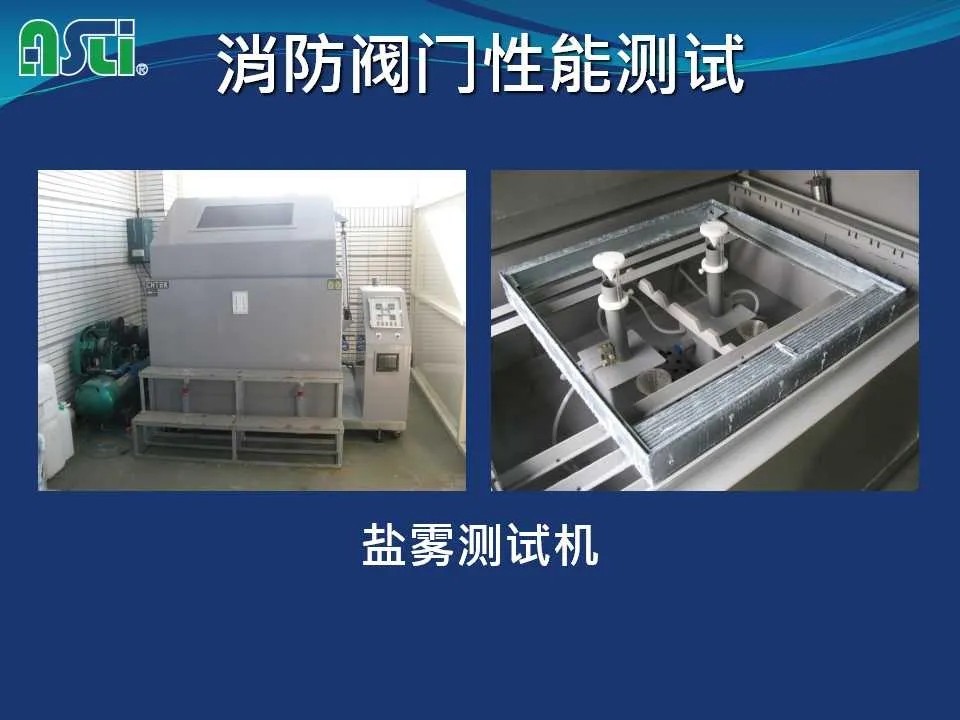

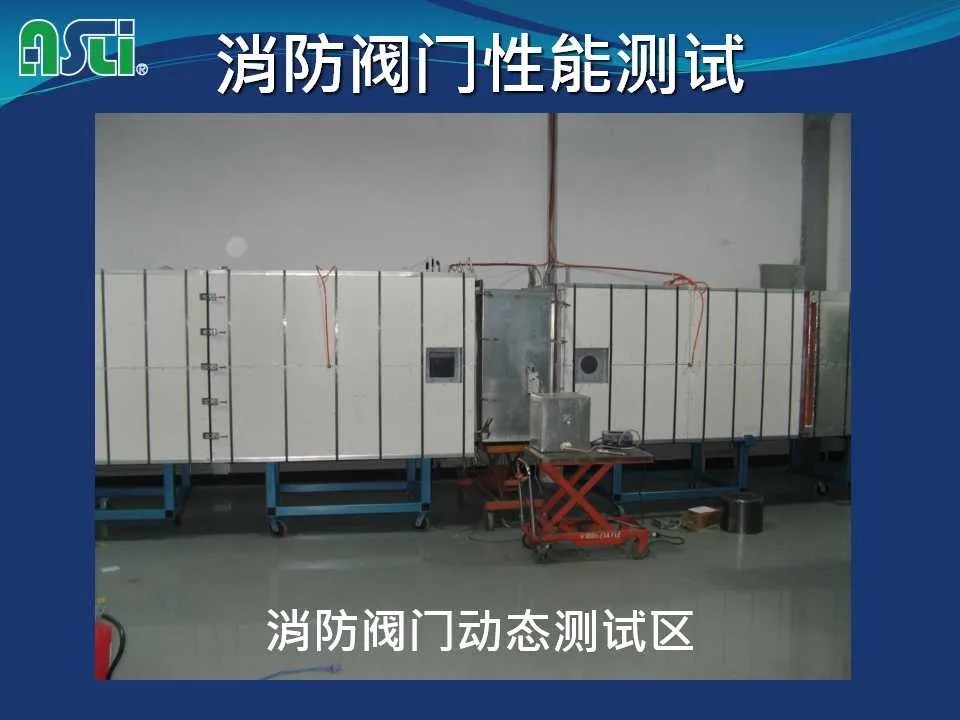

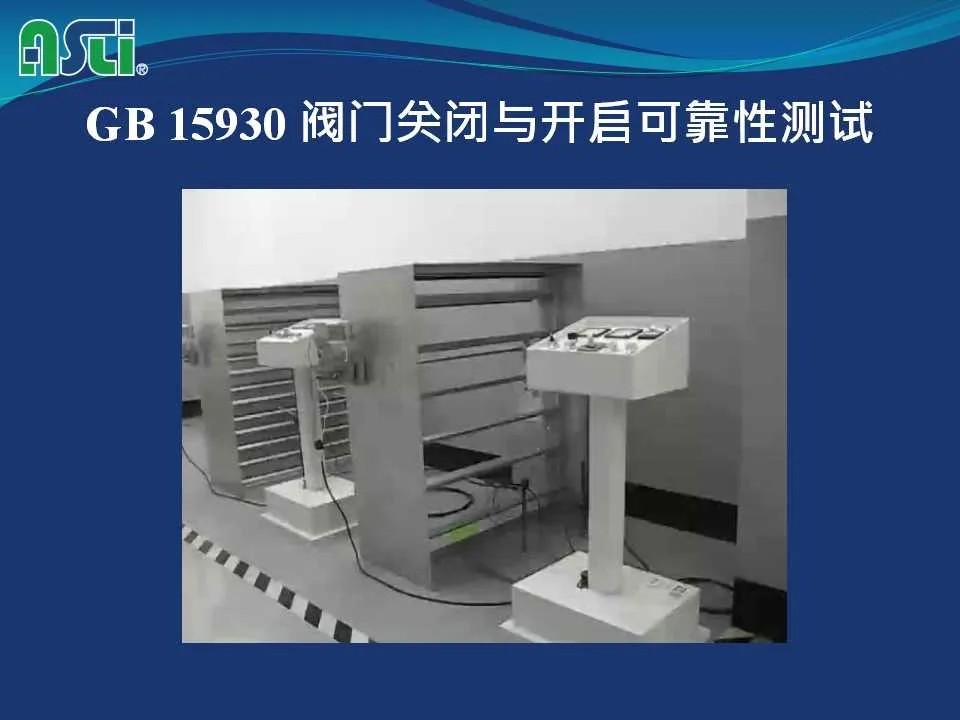

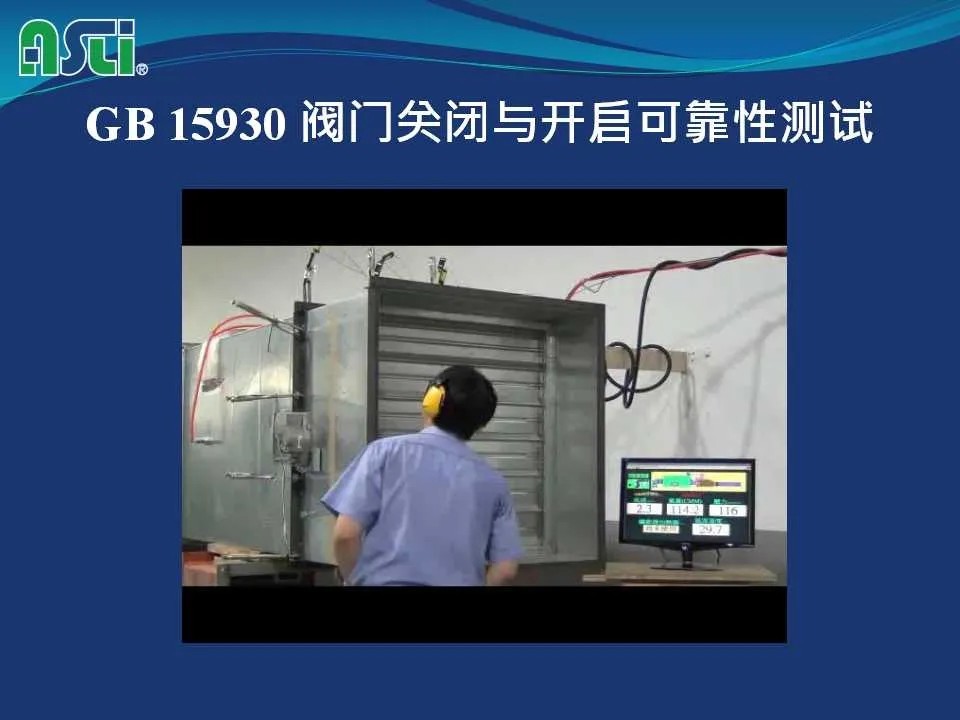

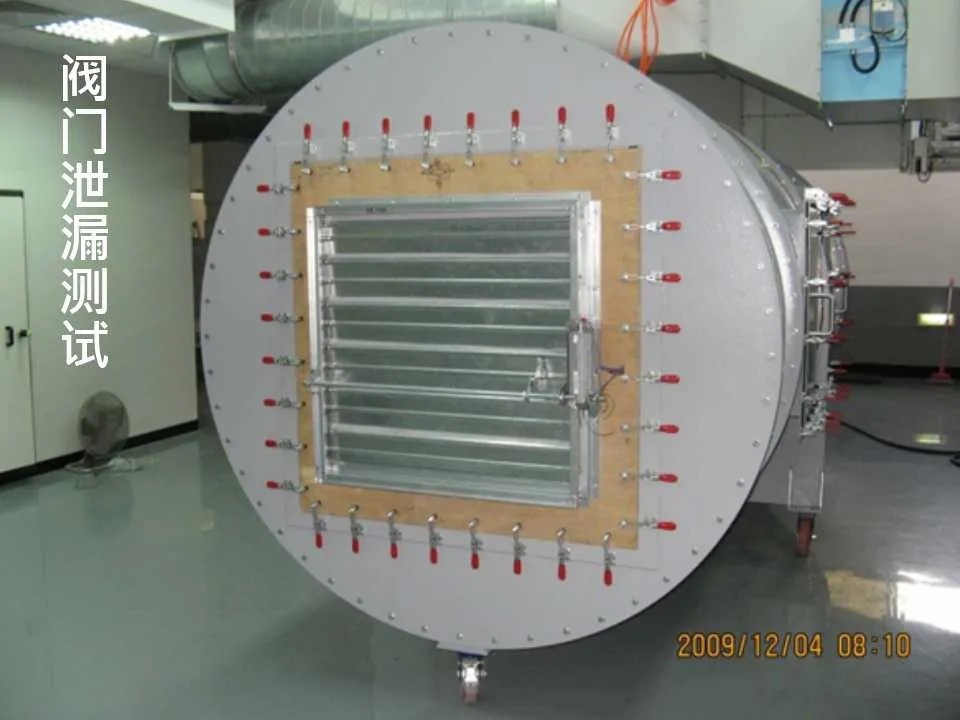

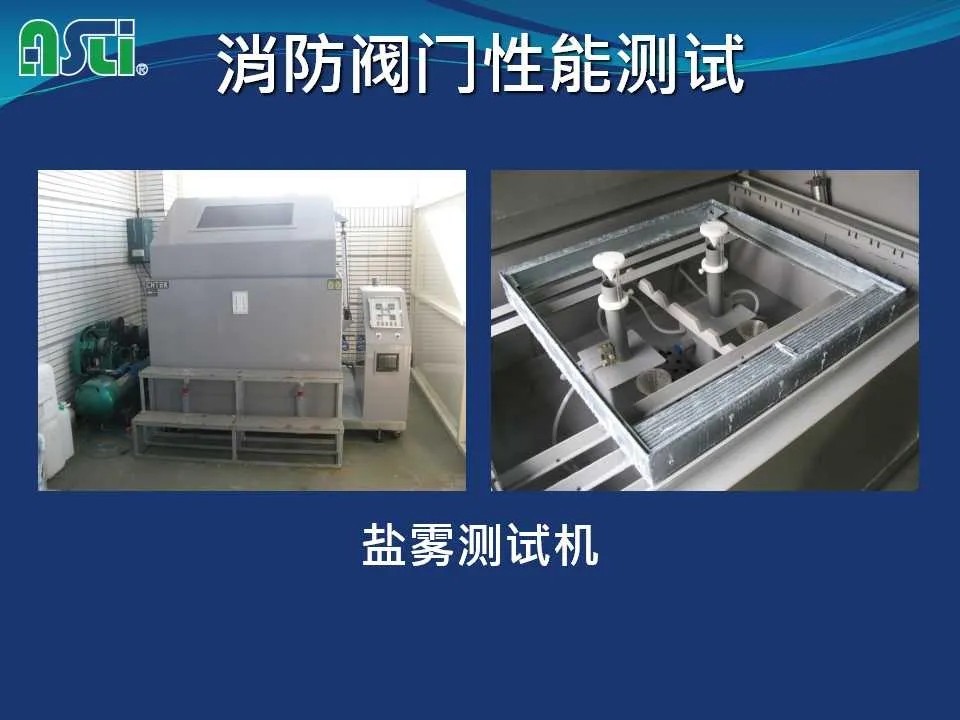

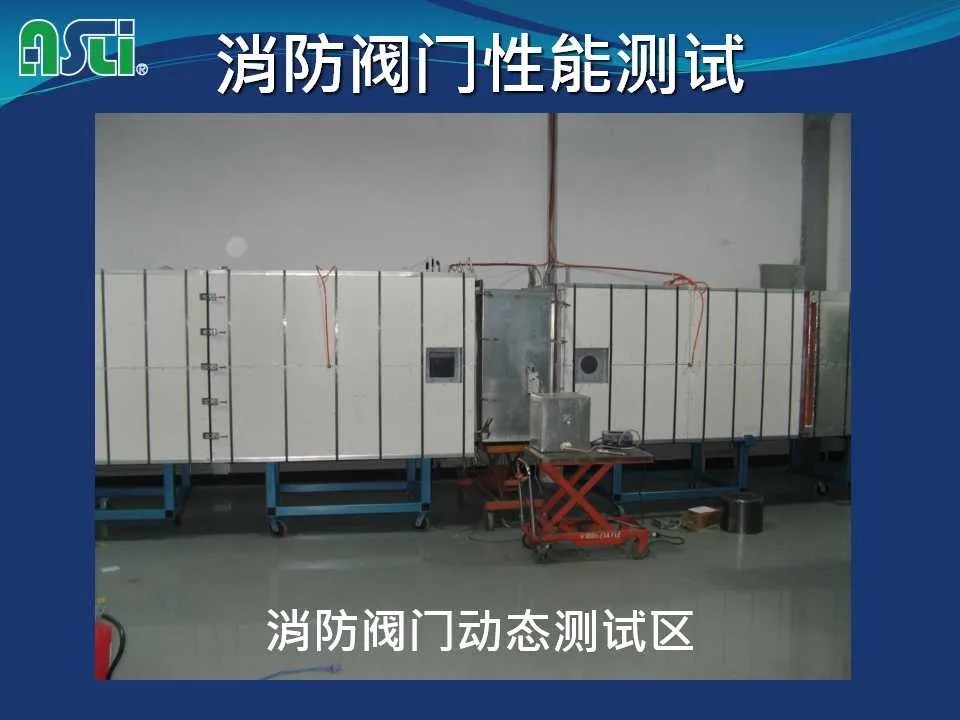

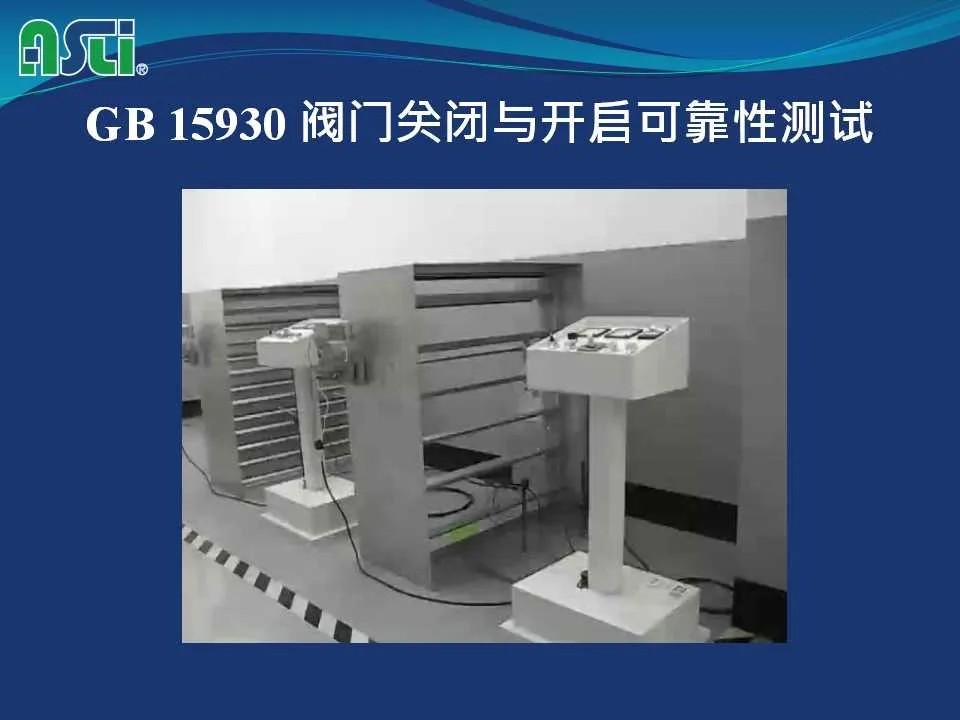

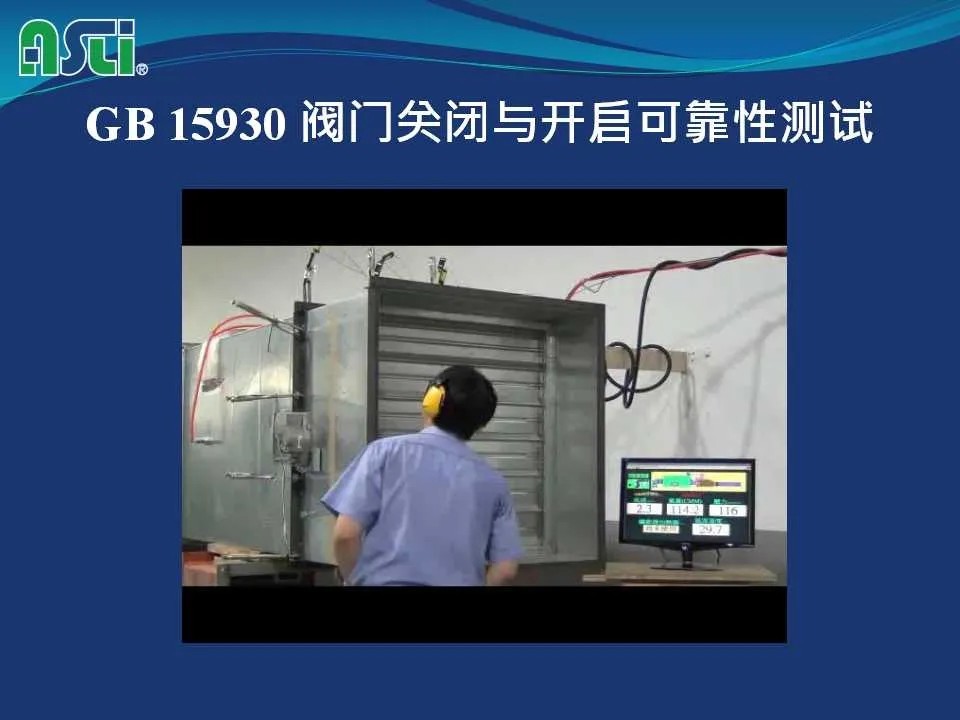

Fire valve performance test

Fire damper classification

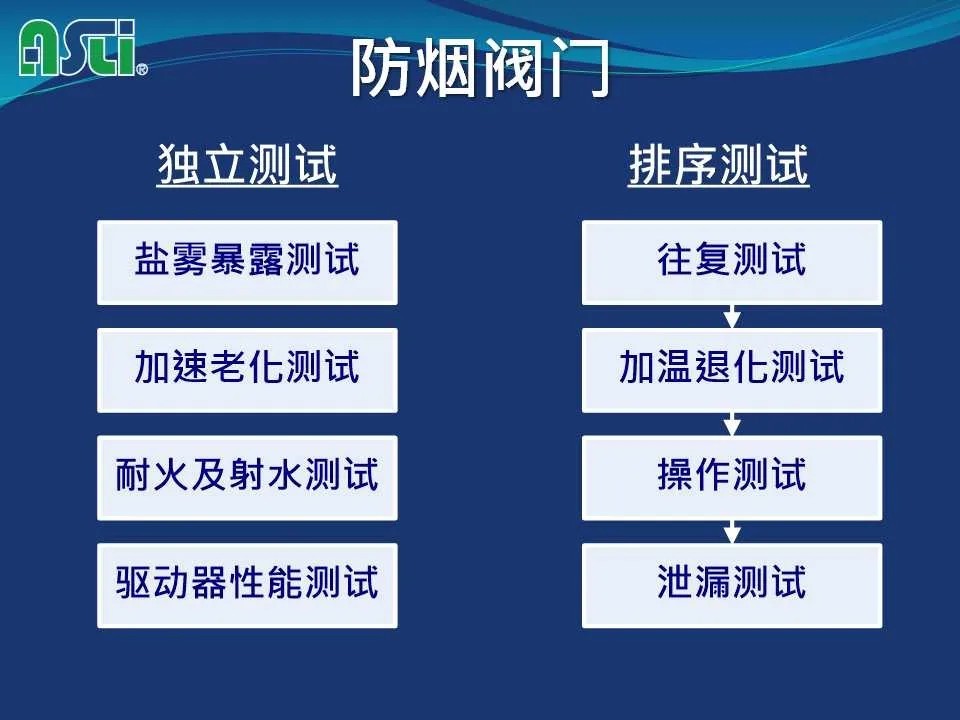

● Smoke damper

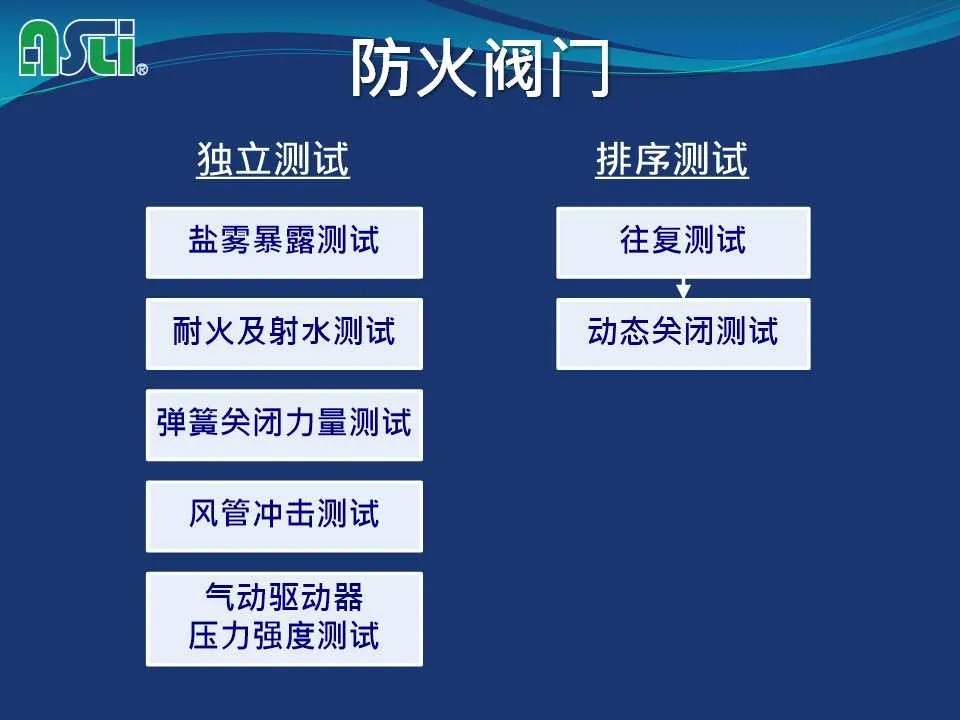

● Fire damper

● Fire/smoke damper

Test Methods

● UL 555 -Fire Damper

● UL555S-Smoke Damper

● AMCA 500-D

Future work - Introducing national standard testing methods to meet the needs of the Chinese market

GB 15930 Fire dampers for building ventilation and smoke exhaust systems

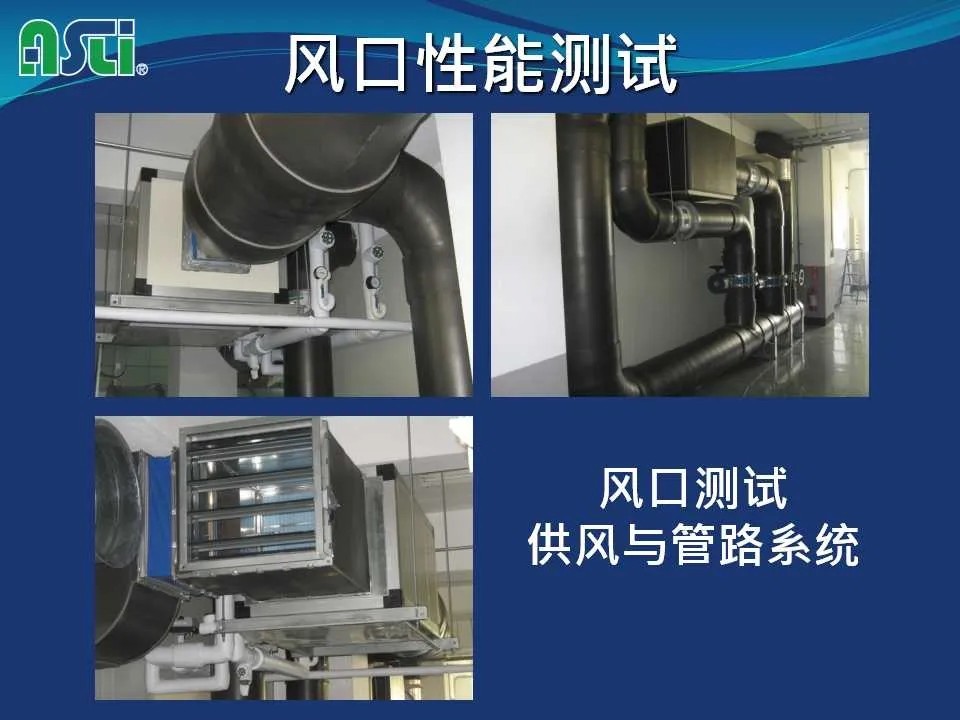

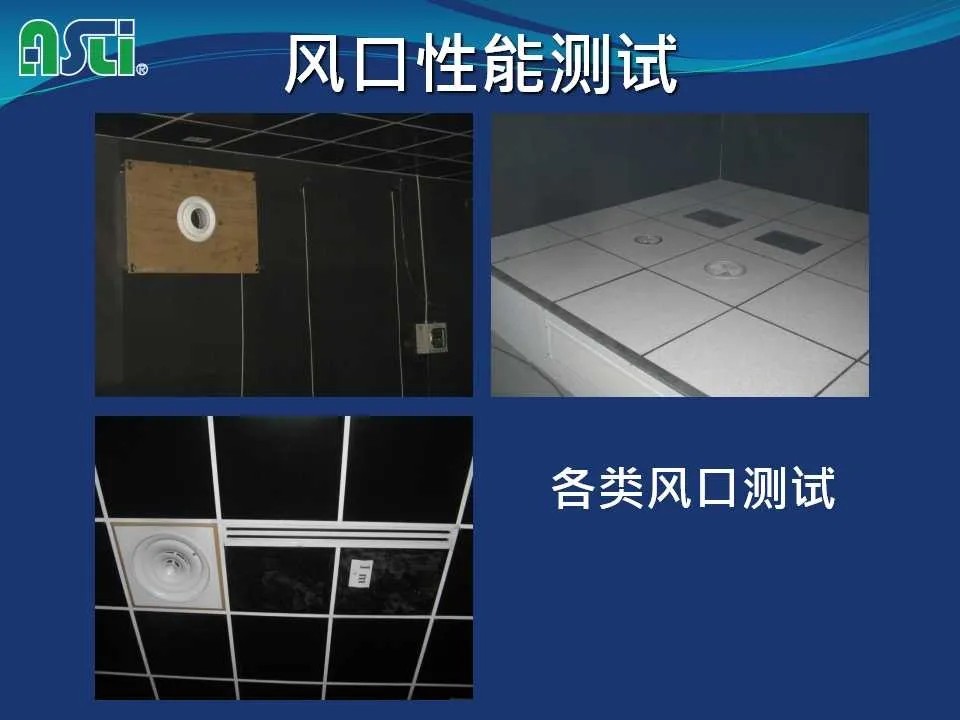

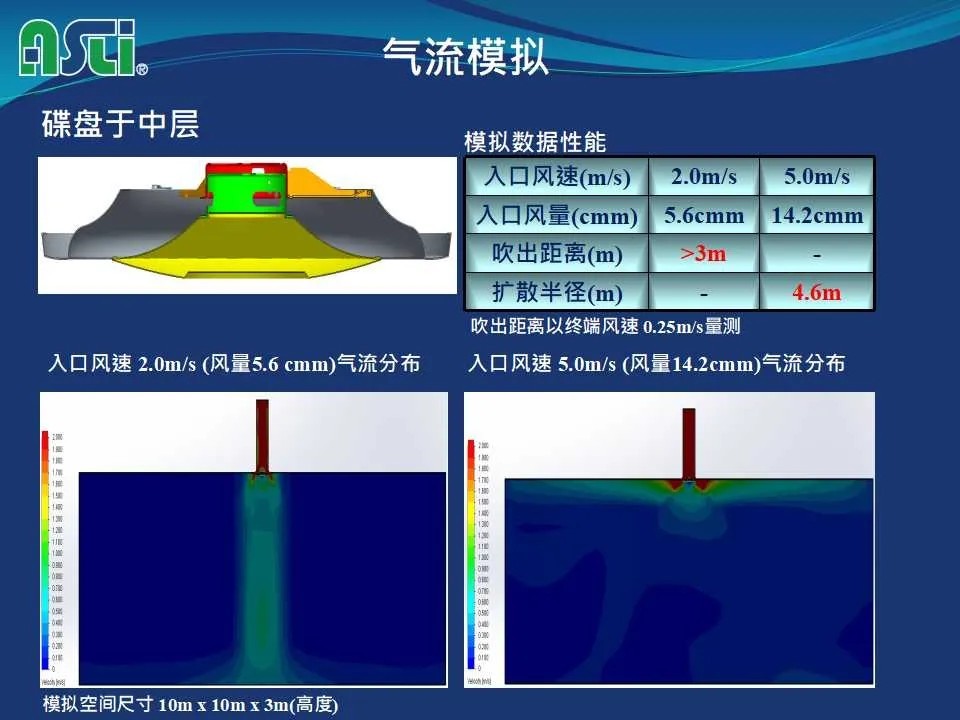

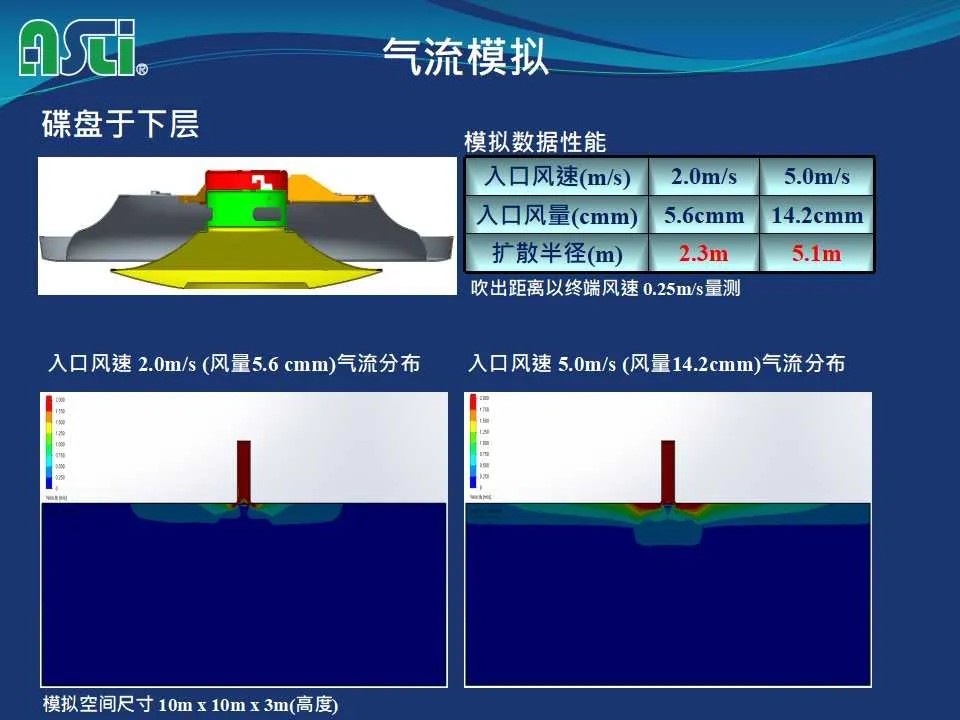

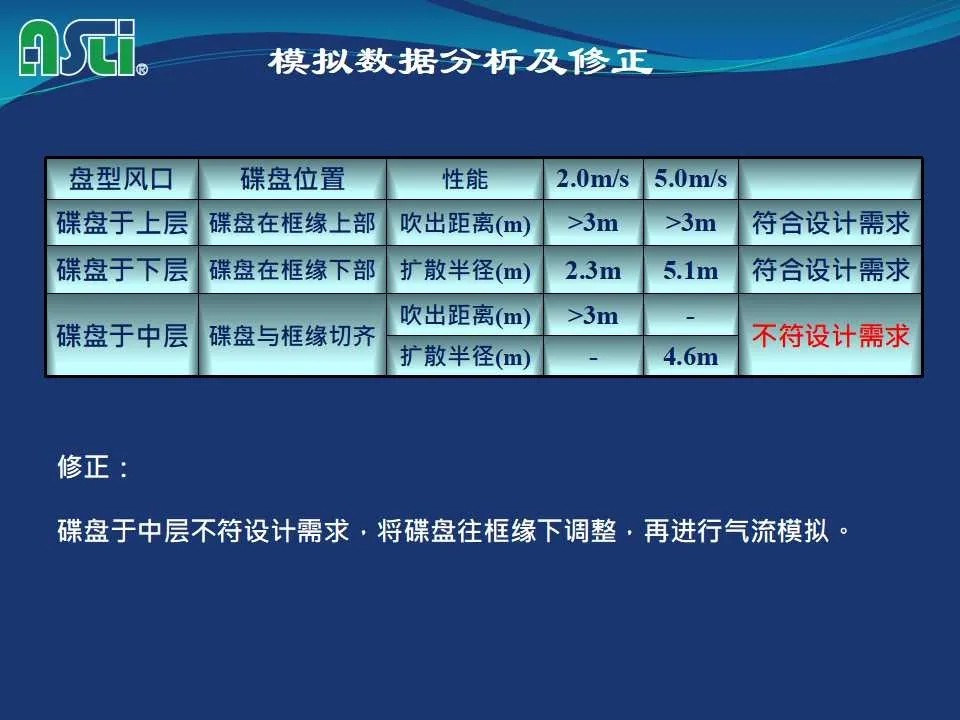

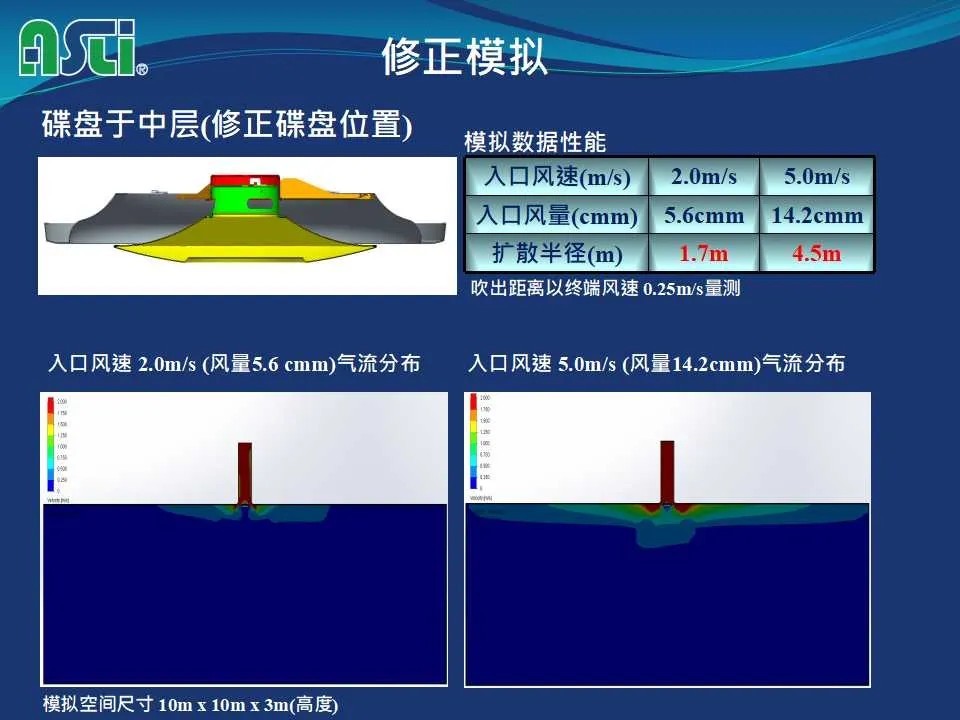

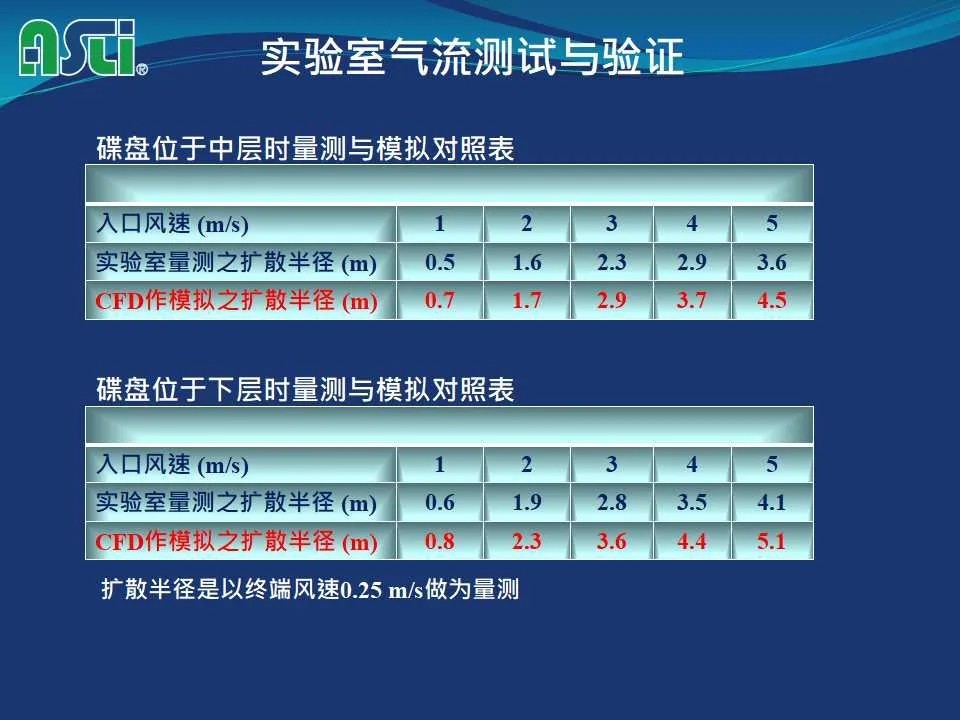

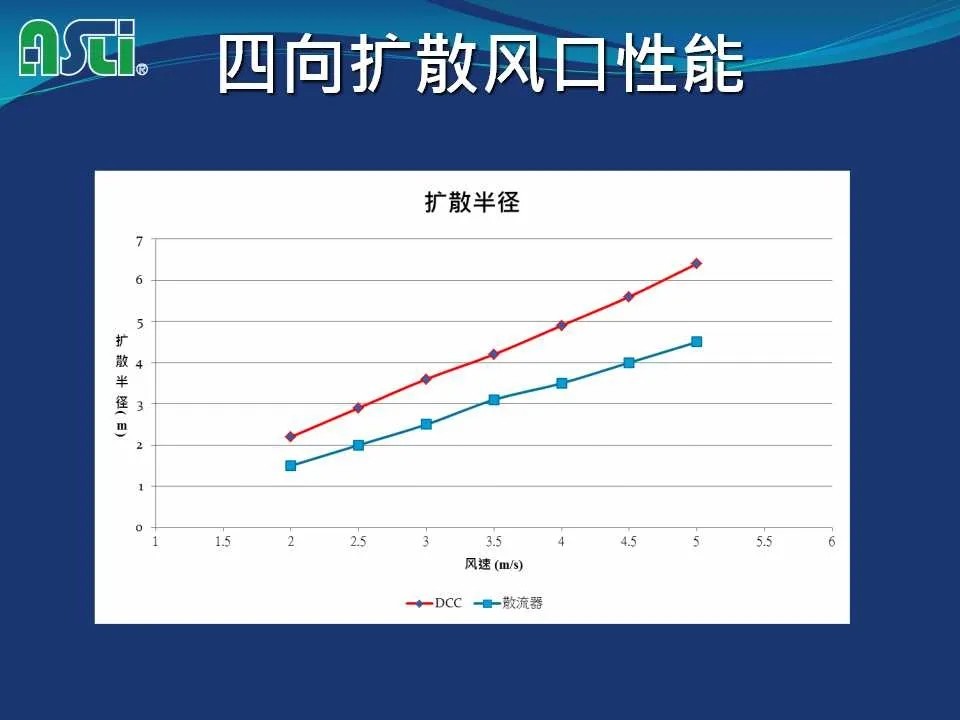

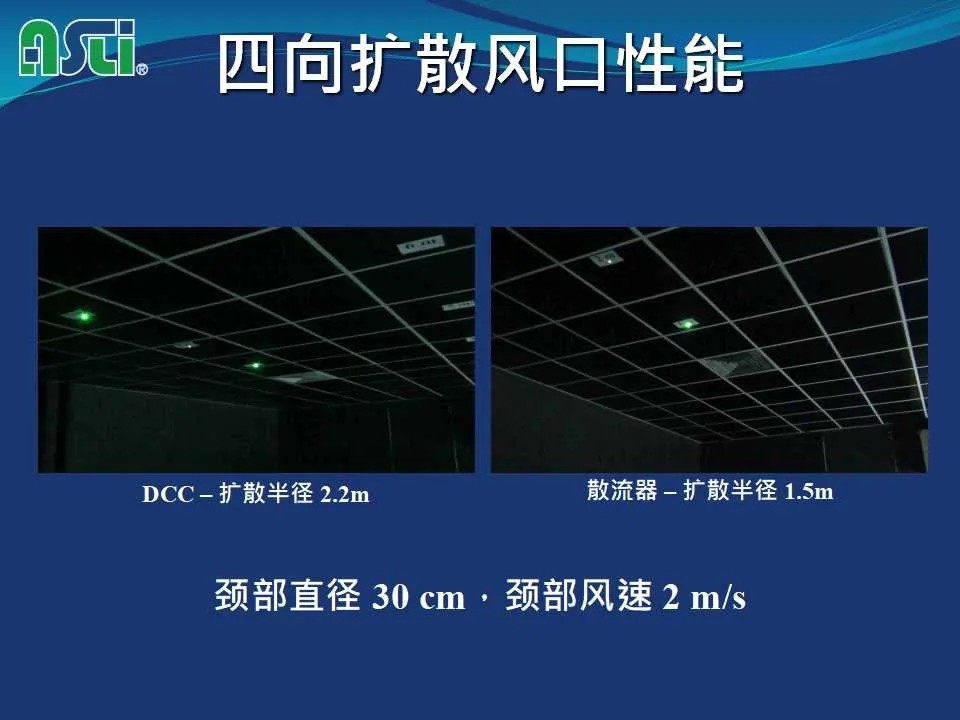

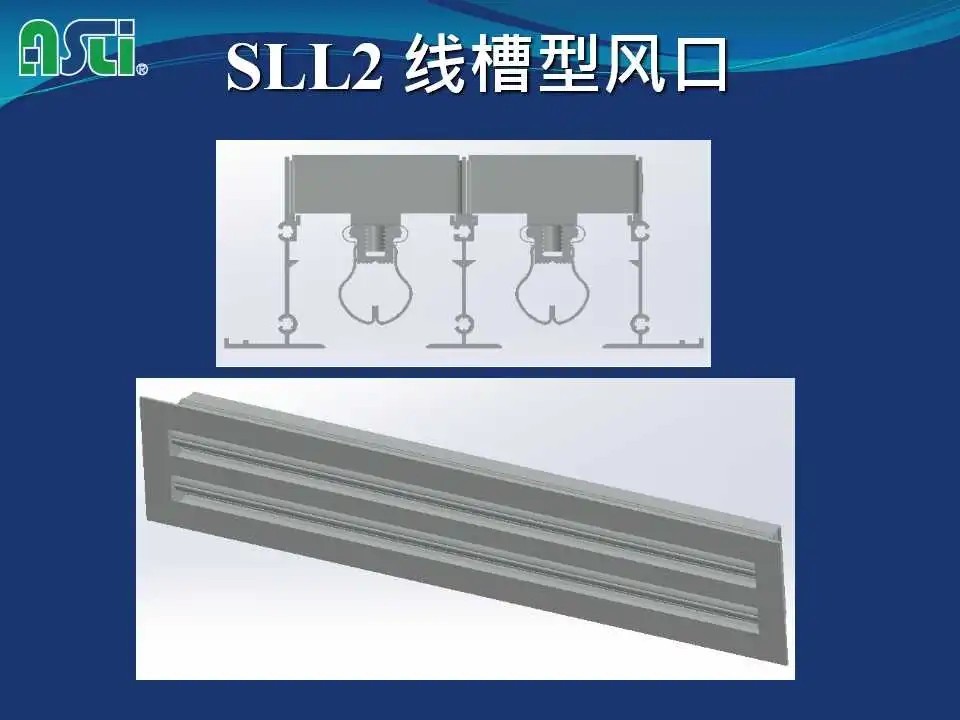

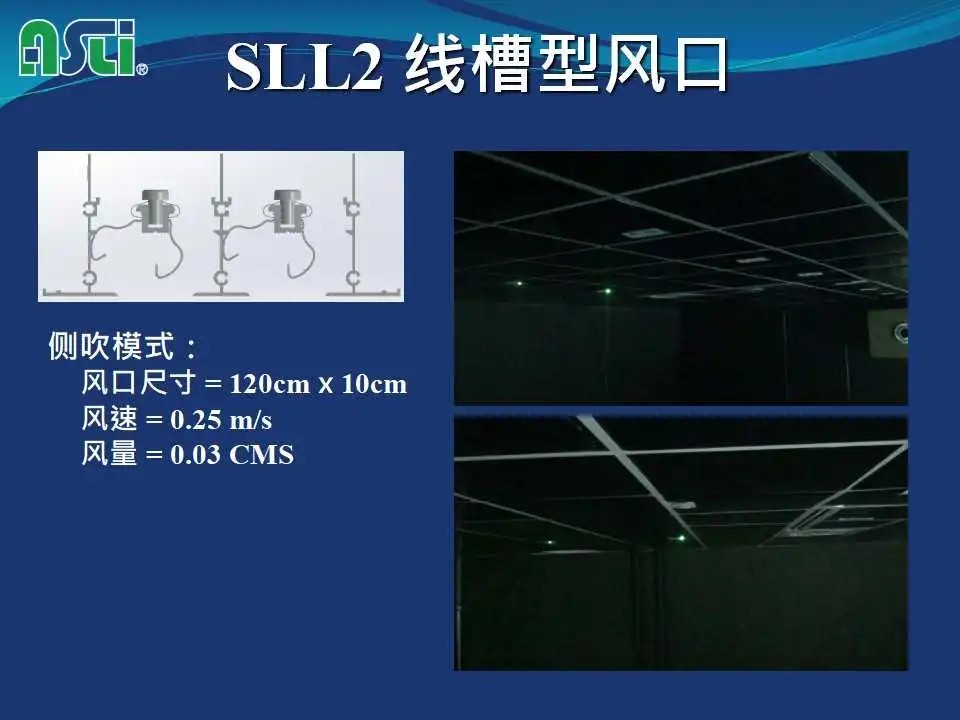

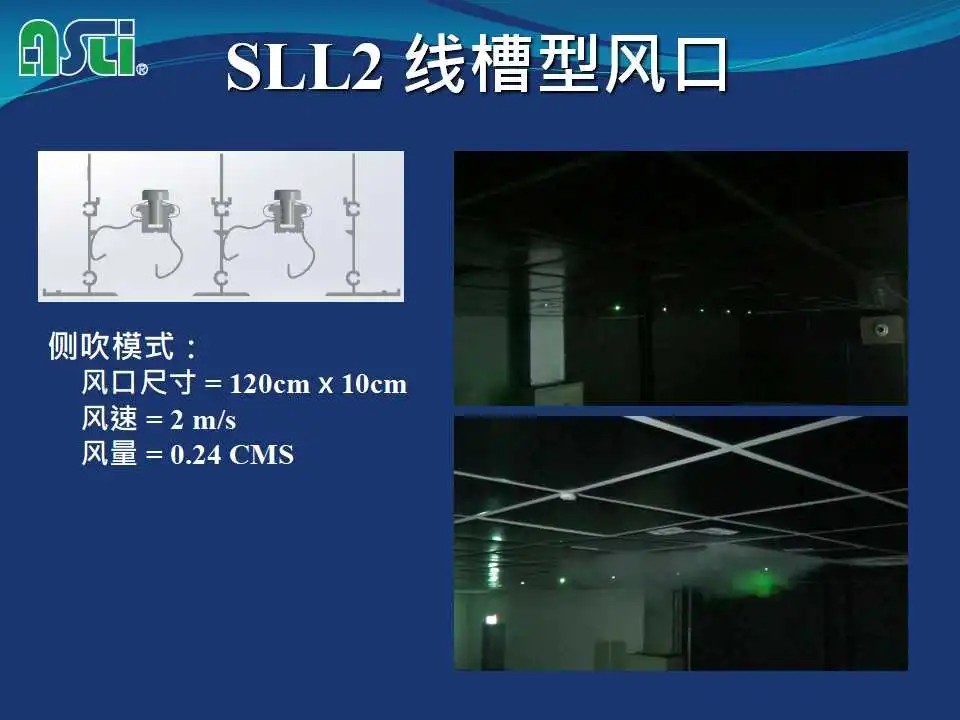

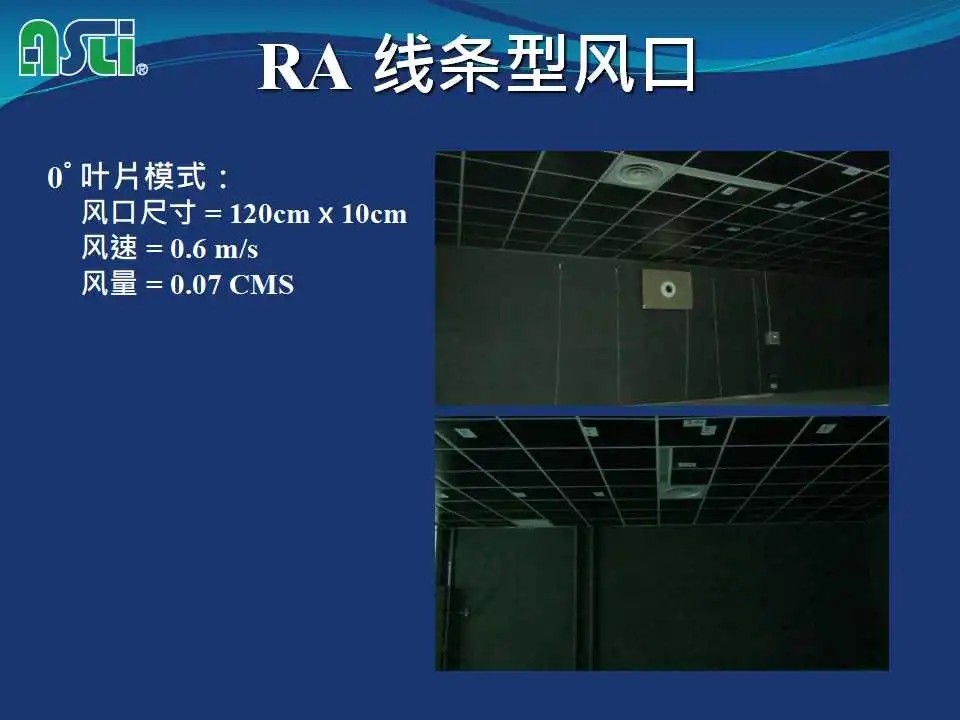

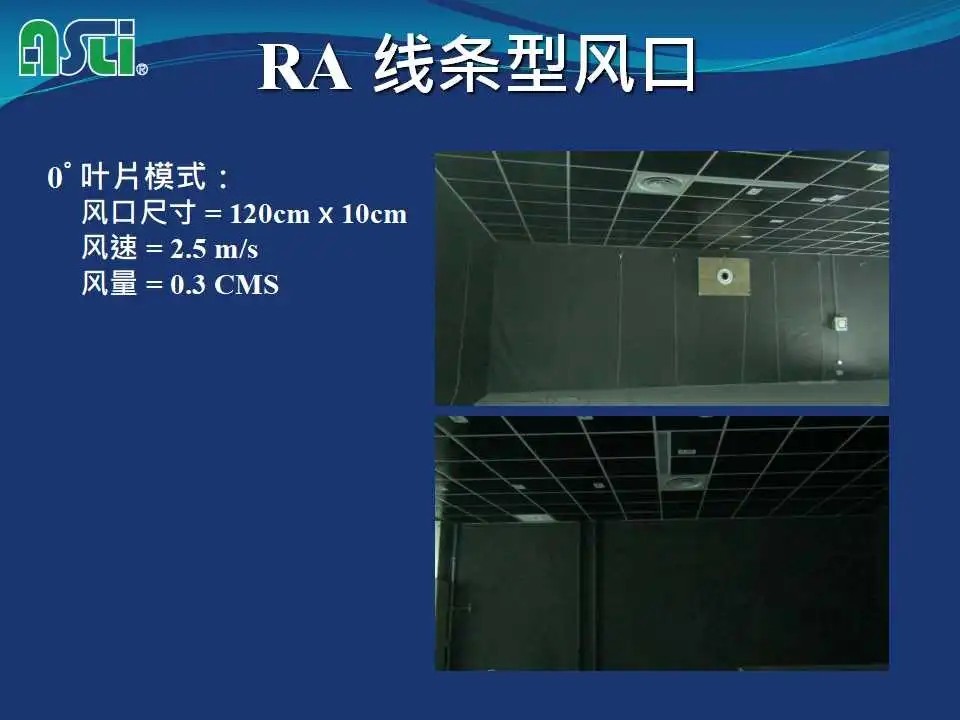

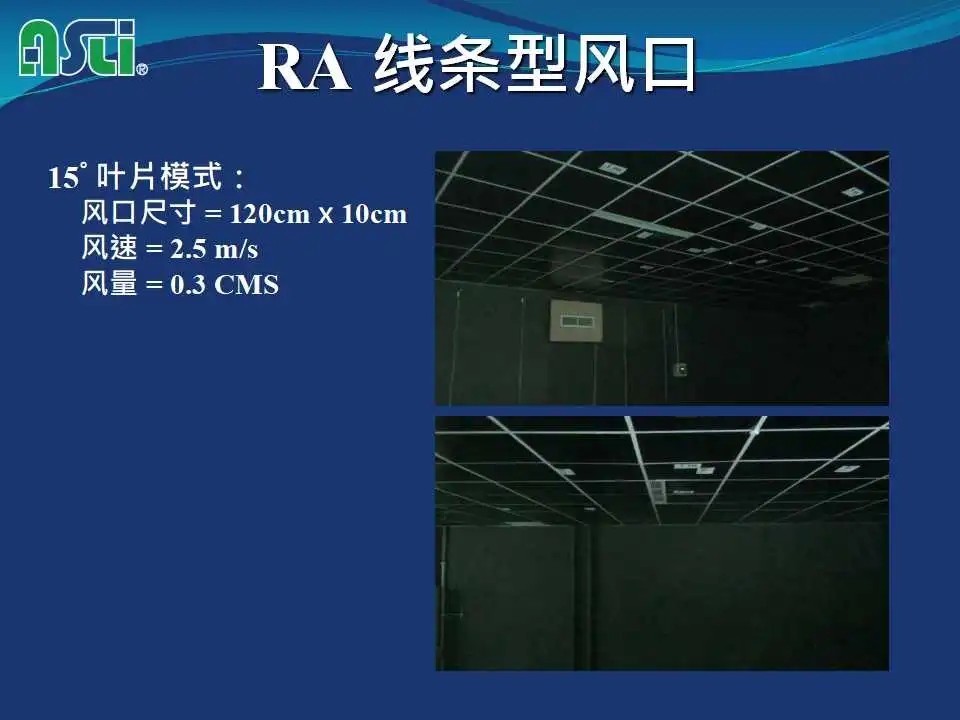

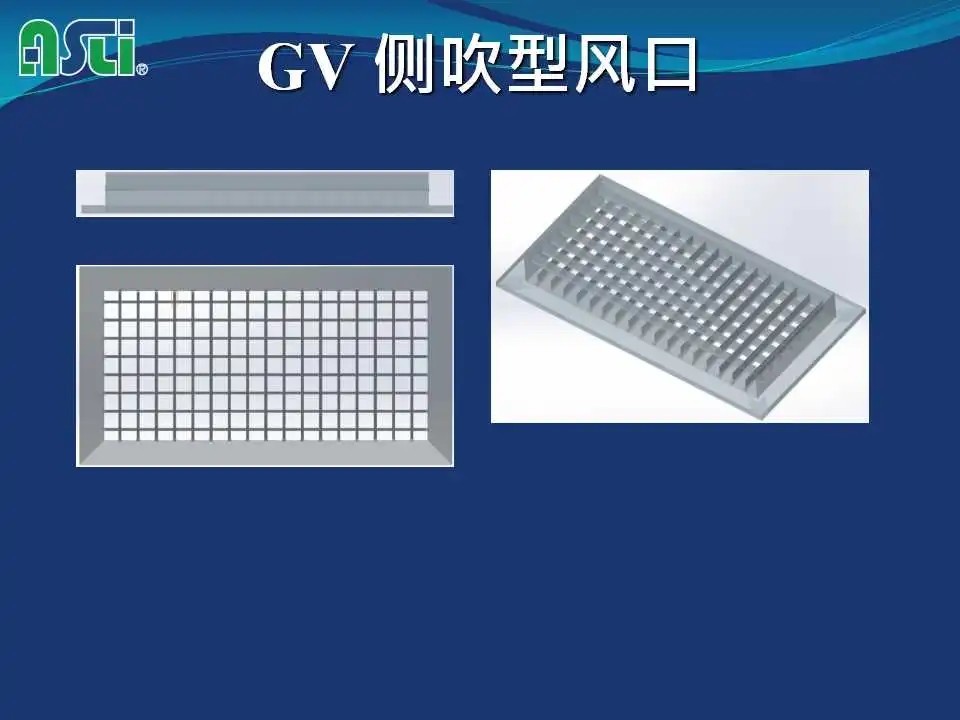

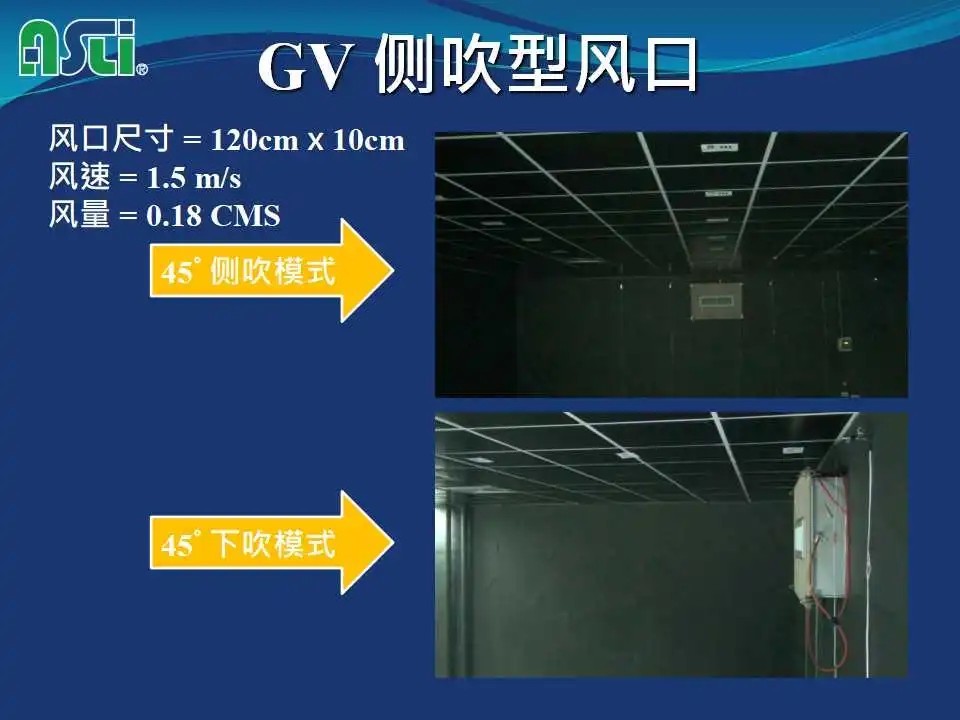

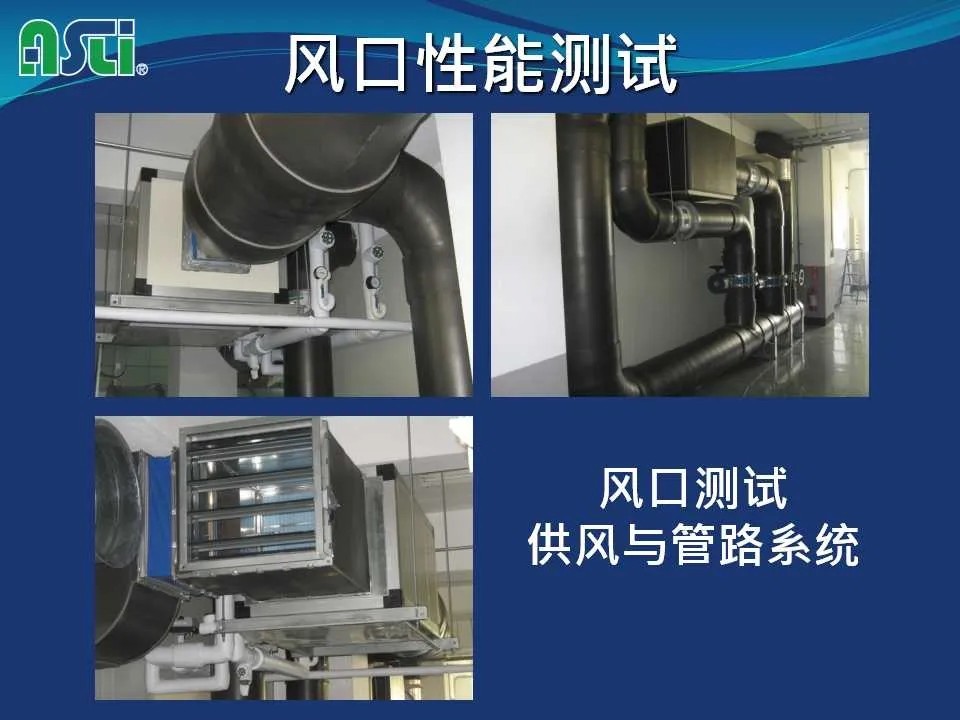

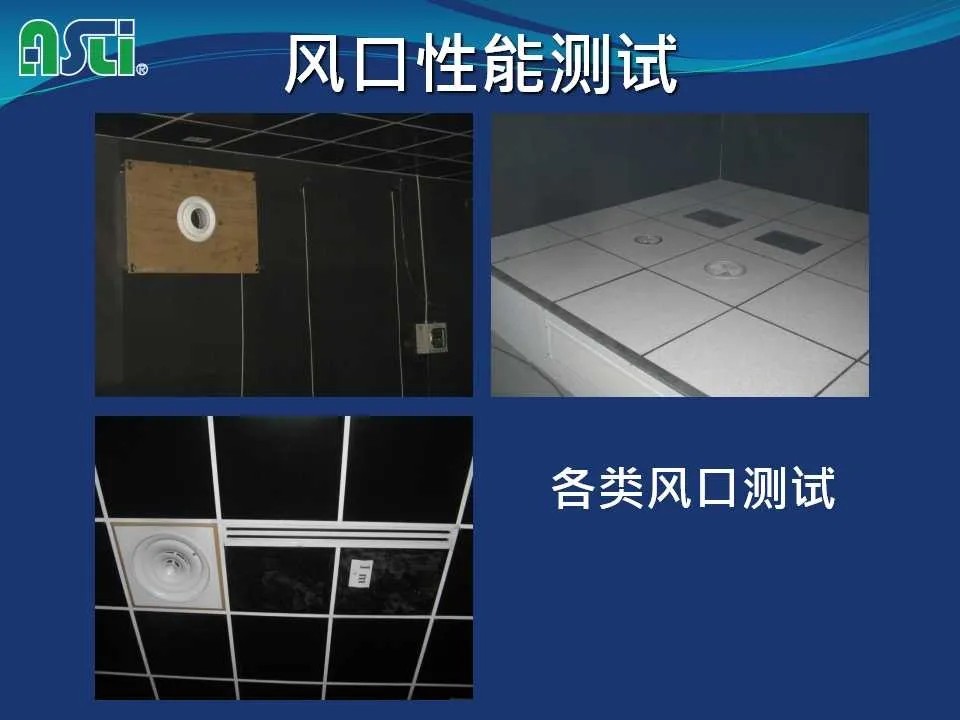

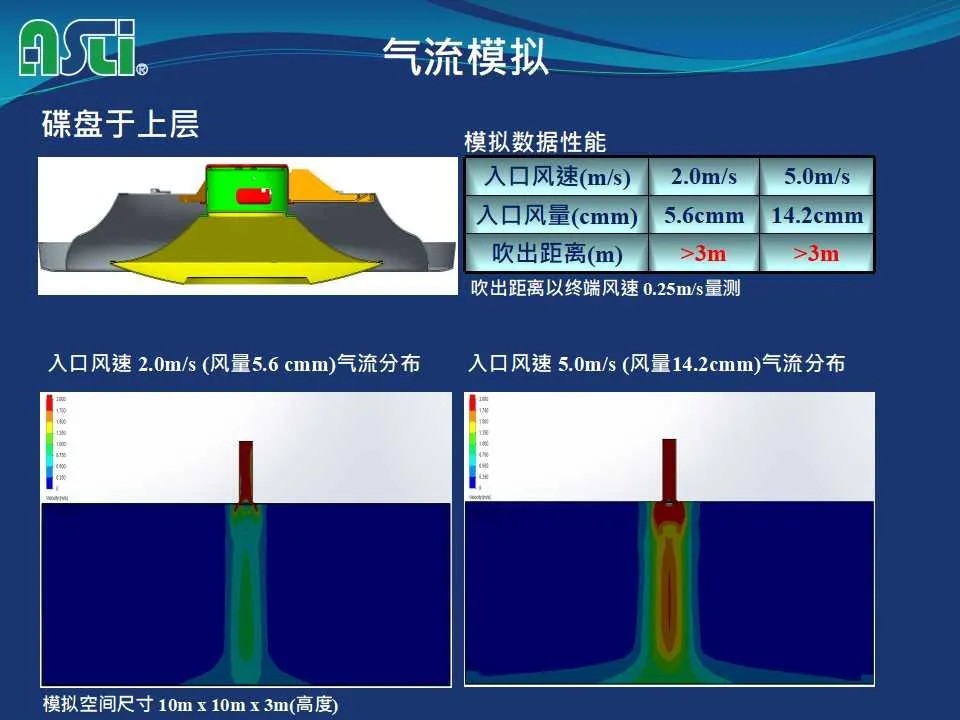

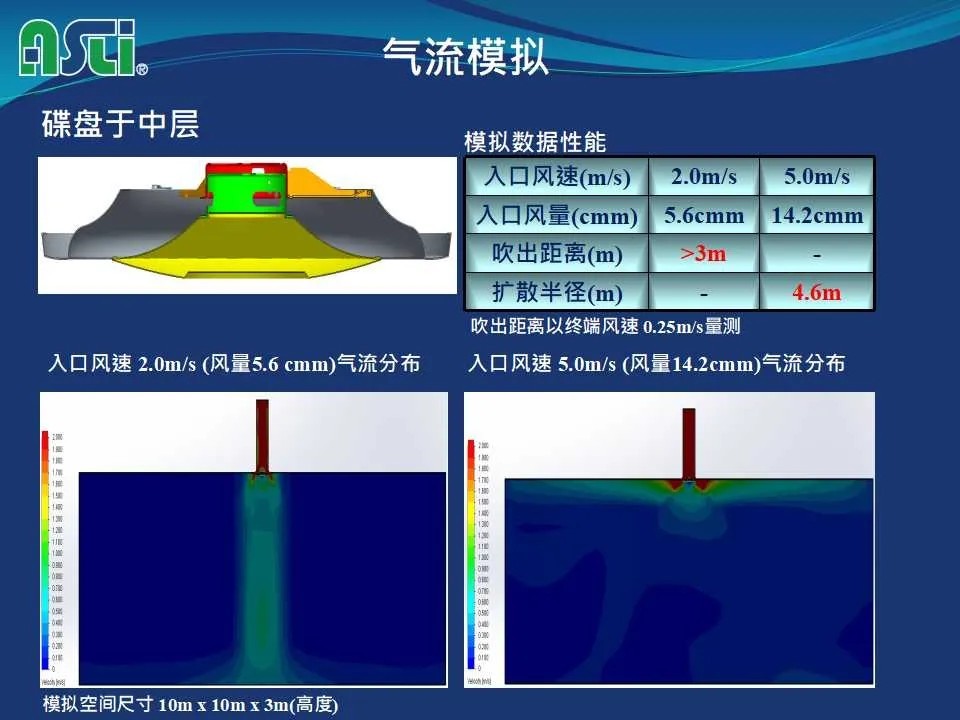

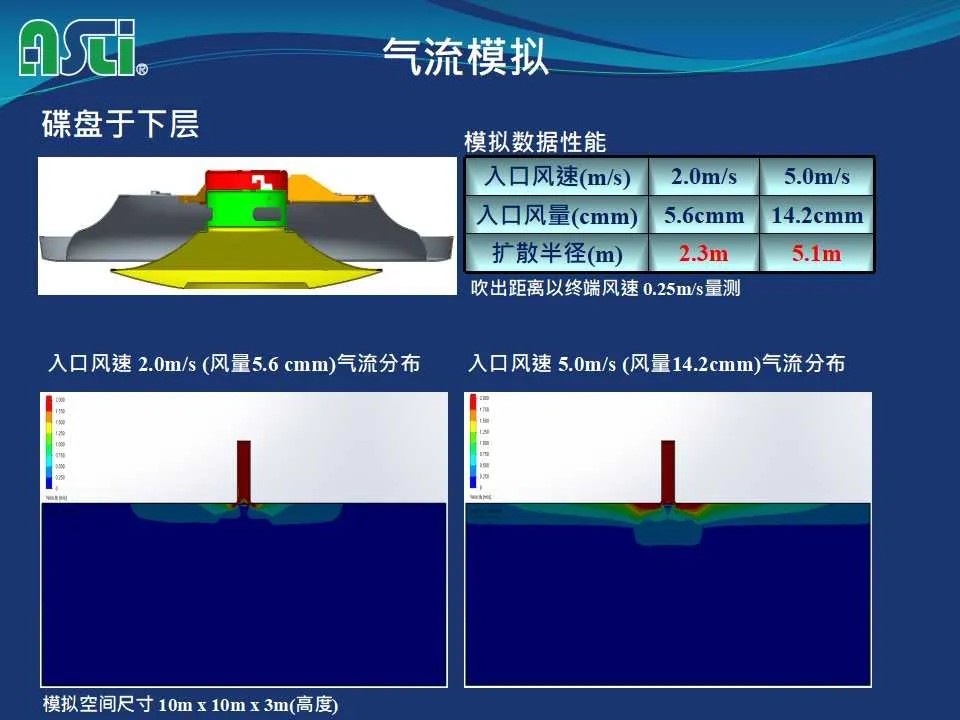

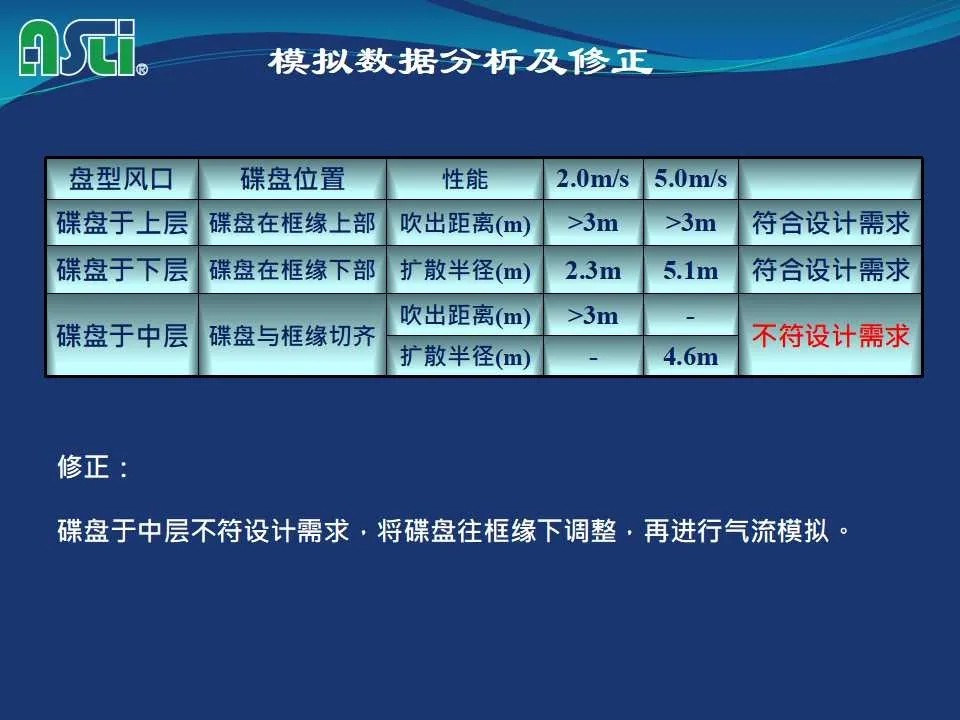

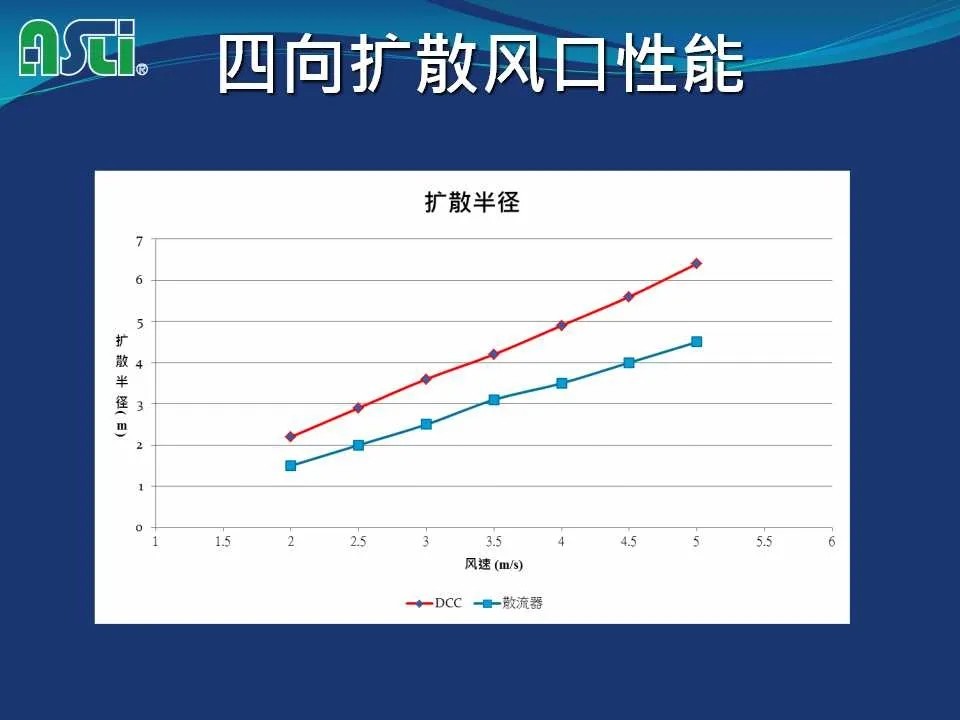

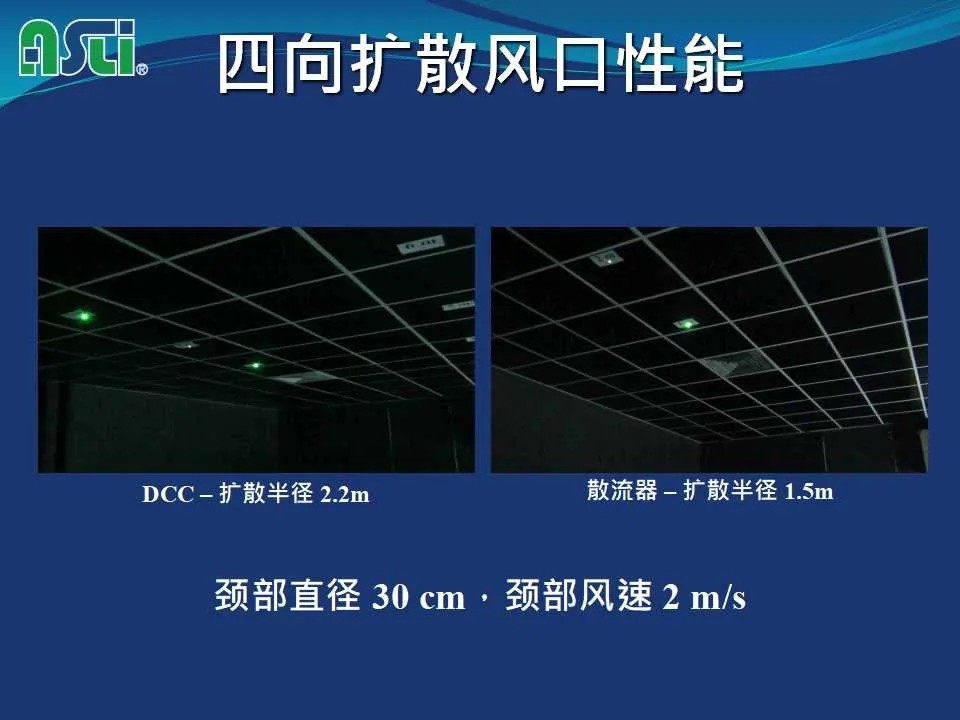

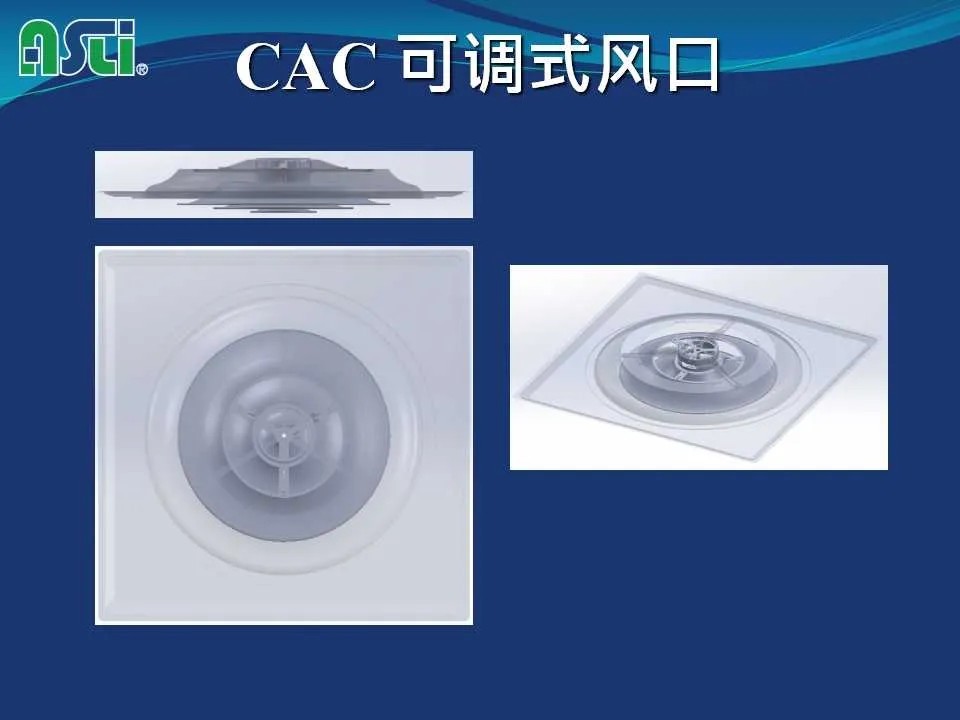

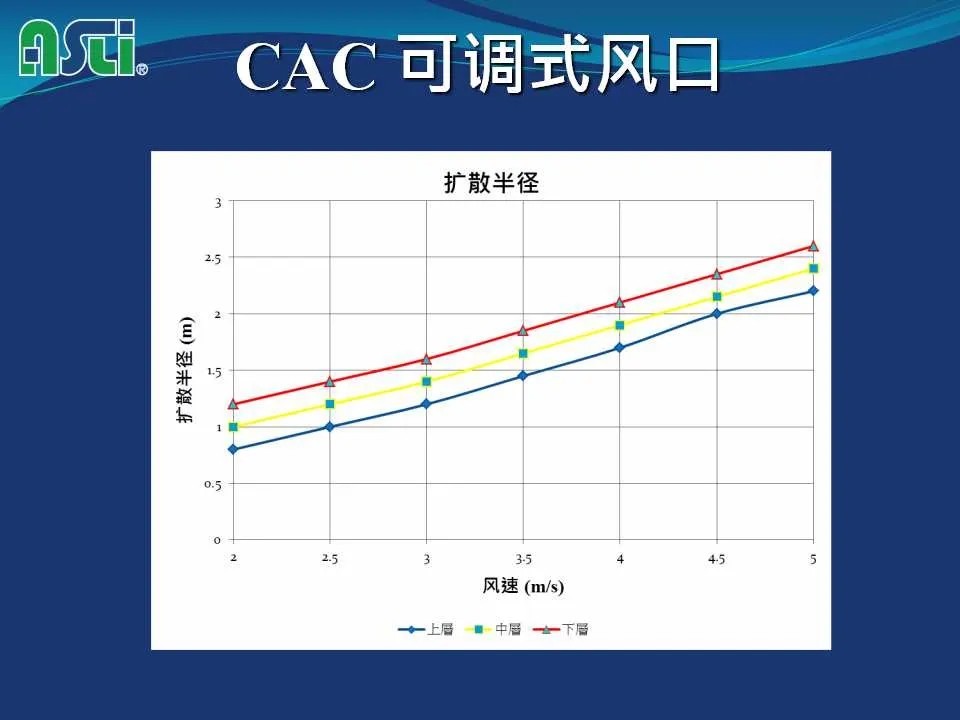

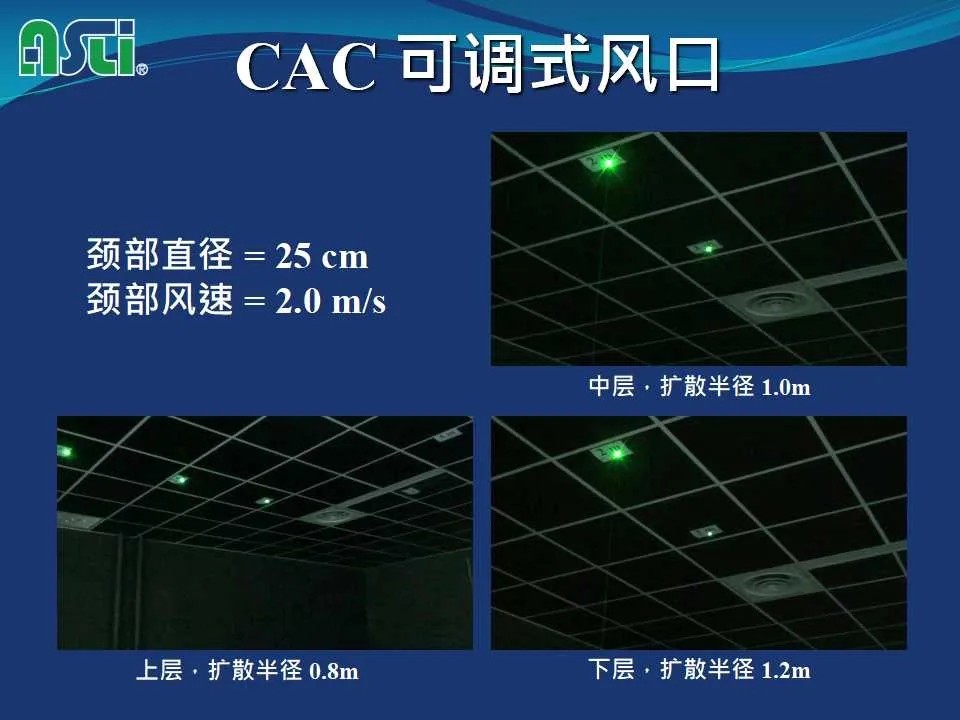

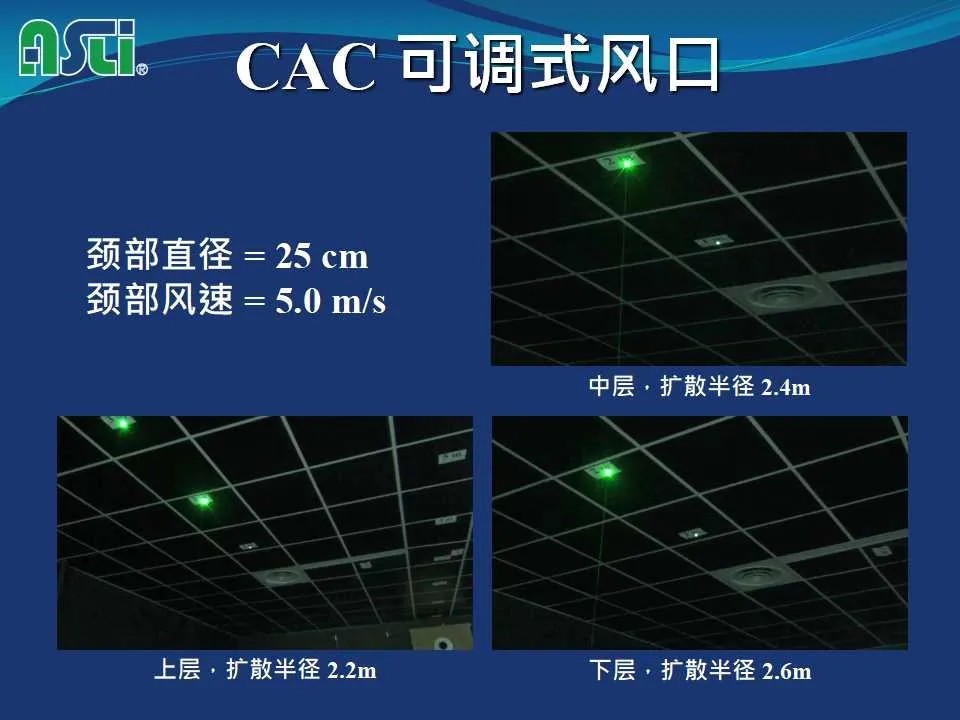

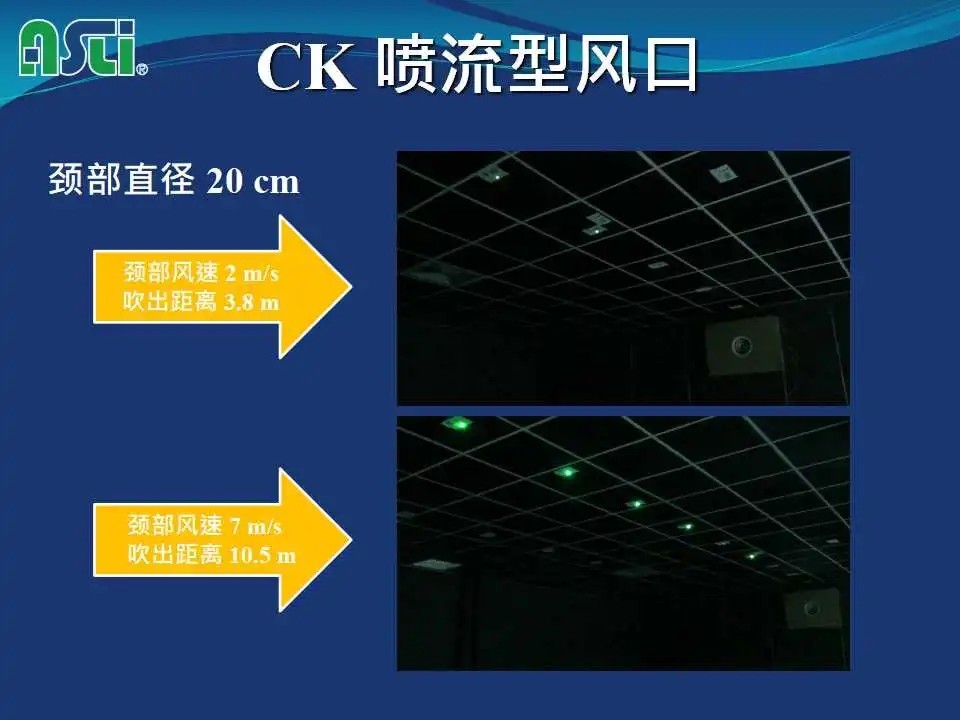

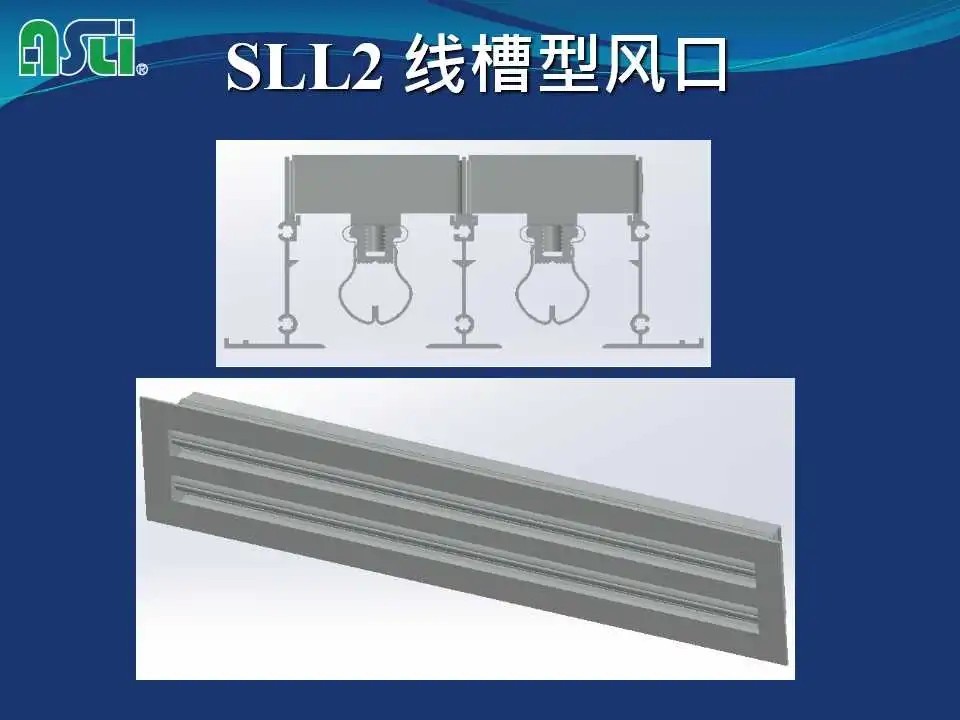

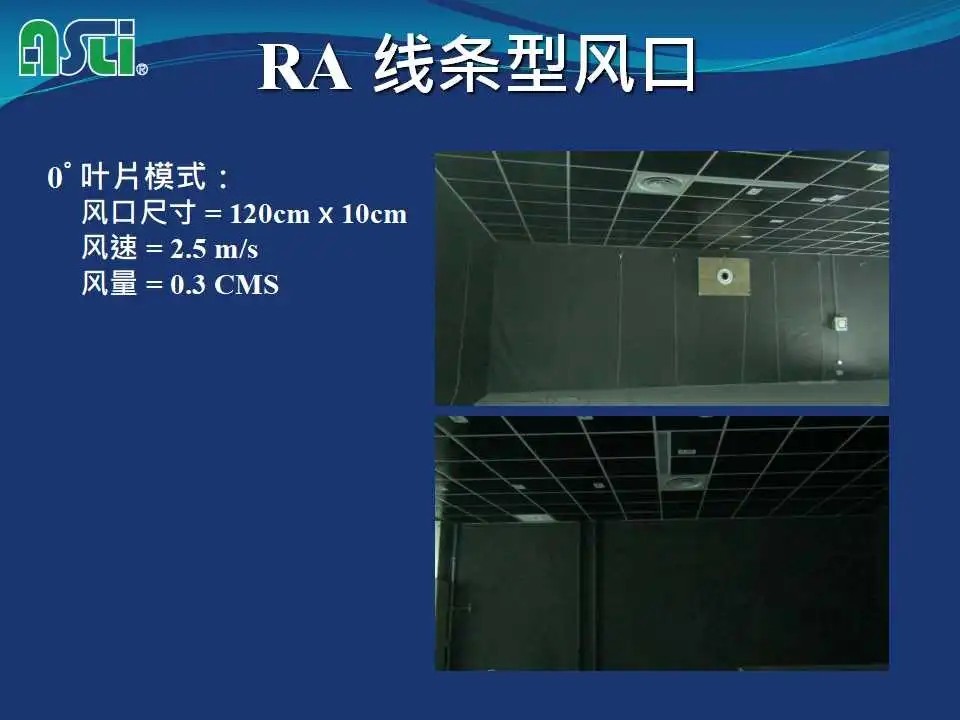

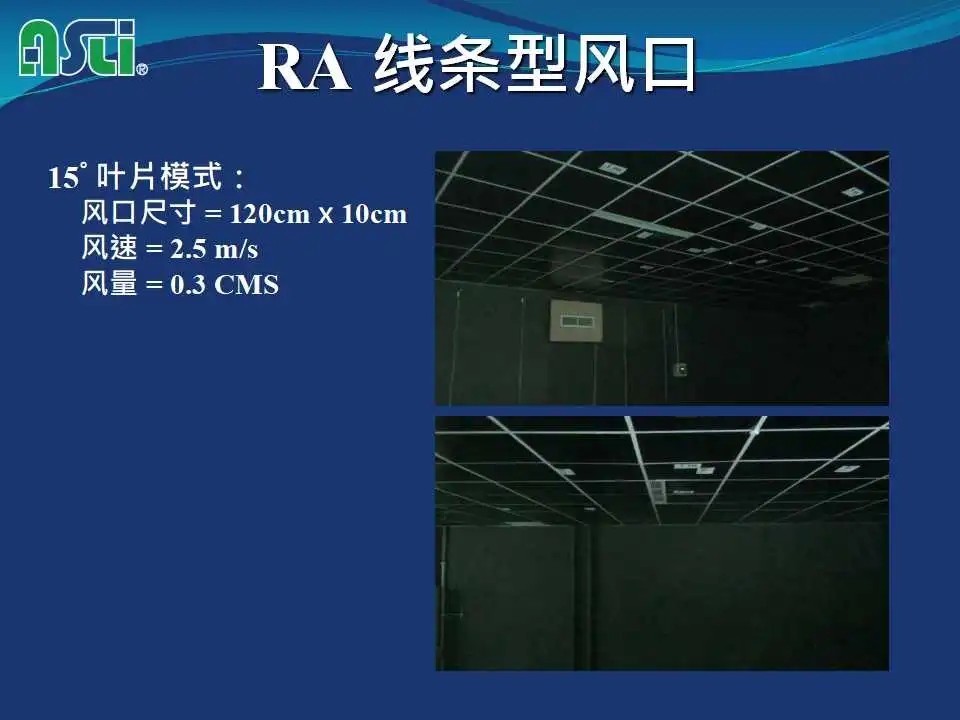

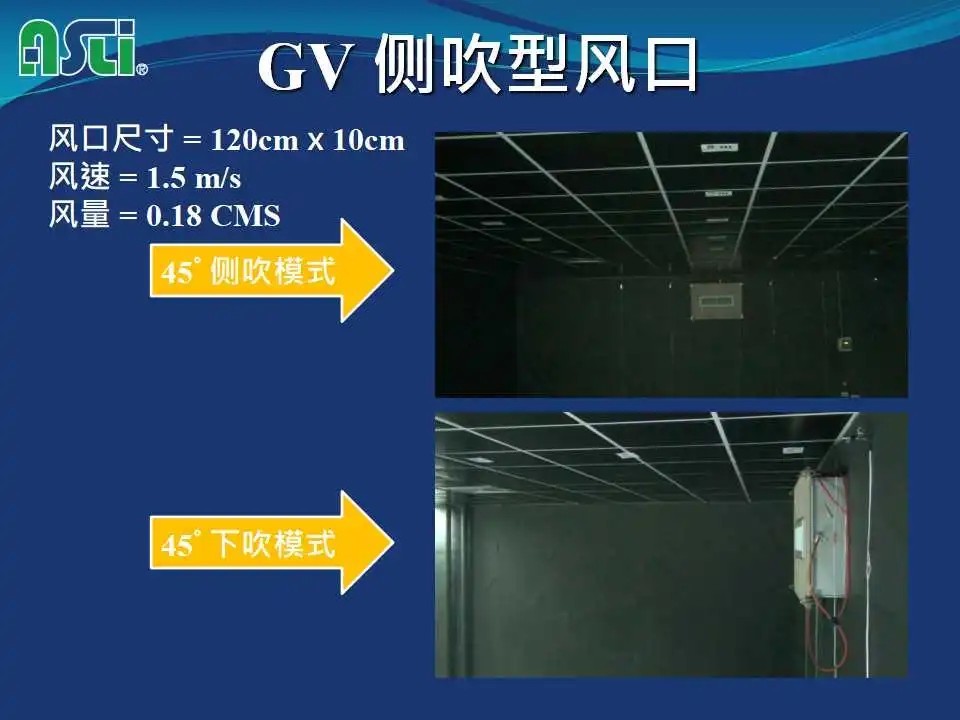

Various air outlet performance tests

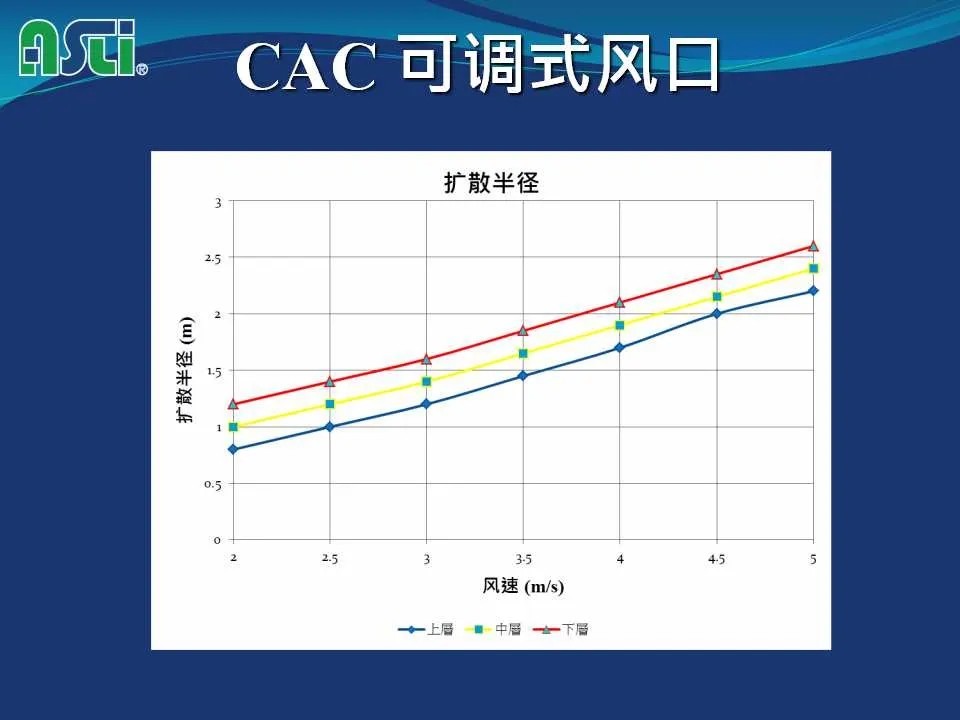

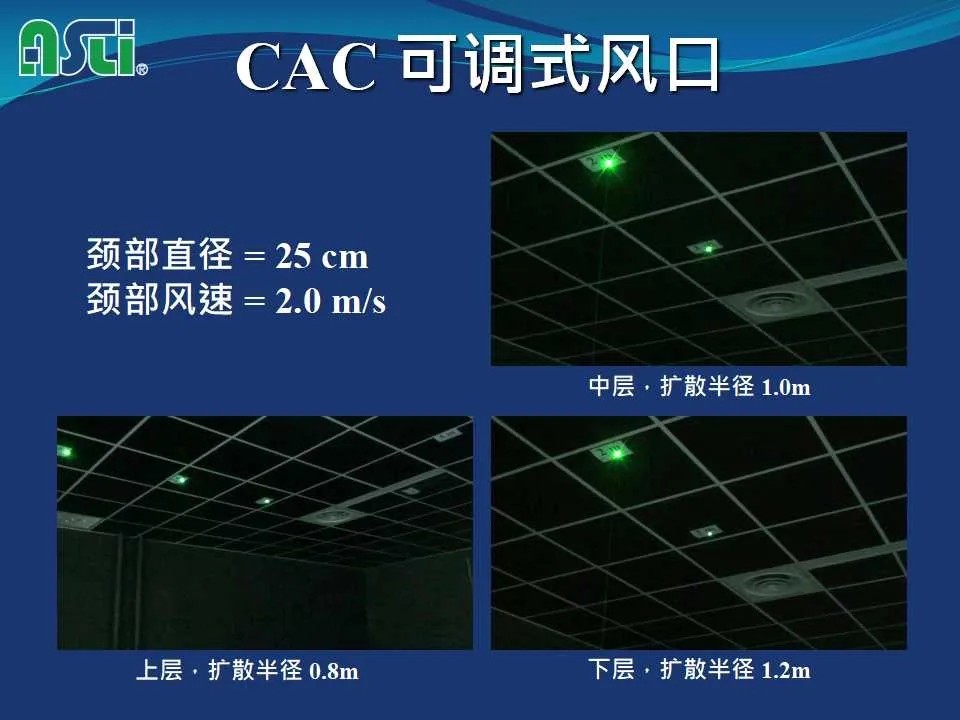

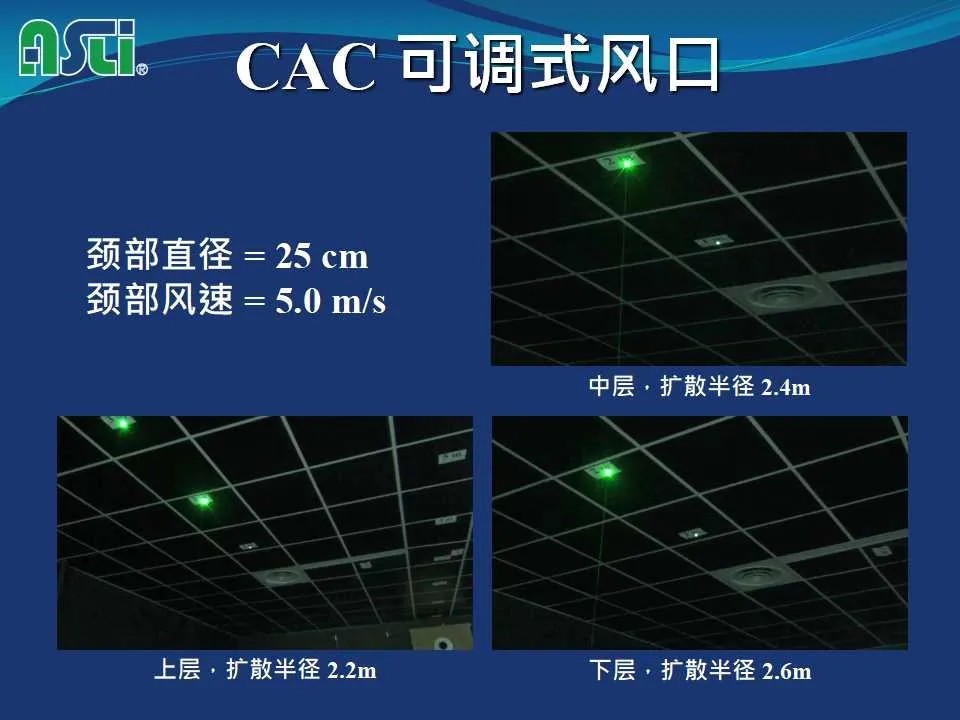

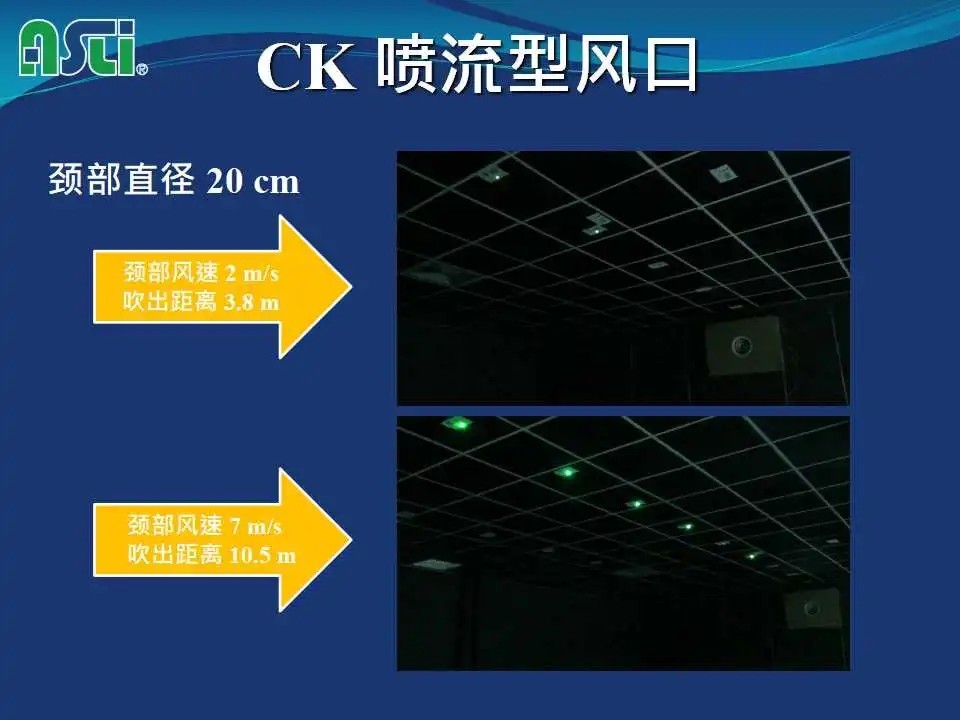

● Method - ANSI-ASHRAE 70 Method of Testing the Performance of Air Outlets and Air Inlets

● Measurement items - Blowing distance (or diffusion radius), pressure loss

Future work - Introducing national standard testing methods to meet the needs of the Chinese market

1. JG/T 14 Ventilation and air conditioning vents

2. JG/T 20 Air distributor performance test method

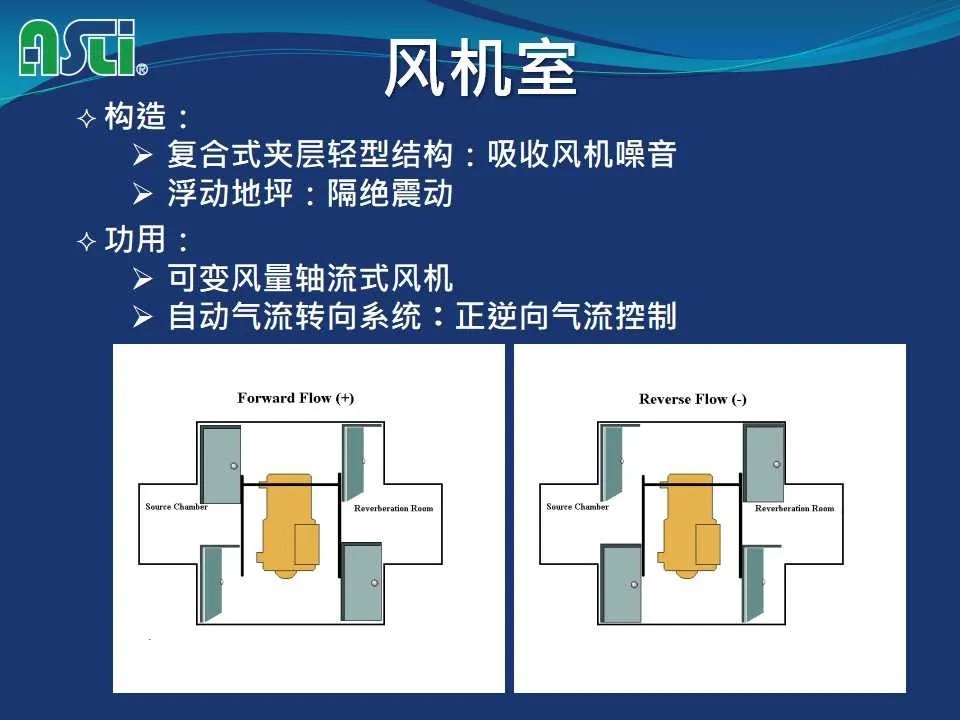

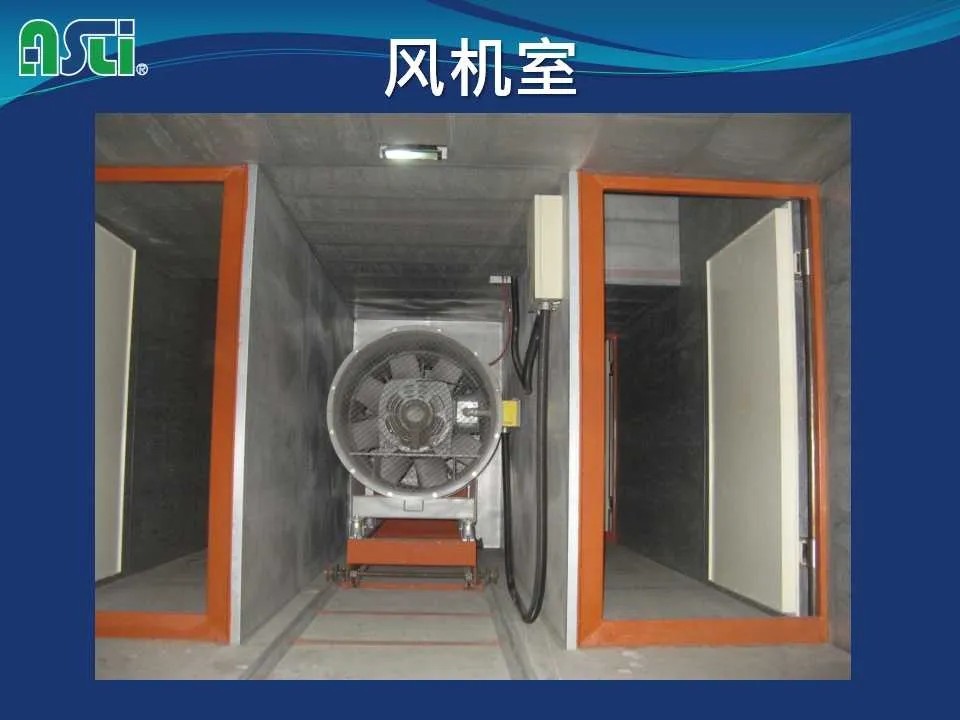

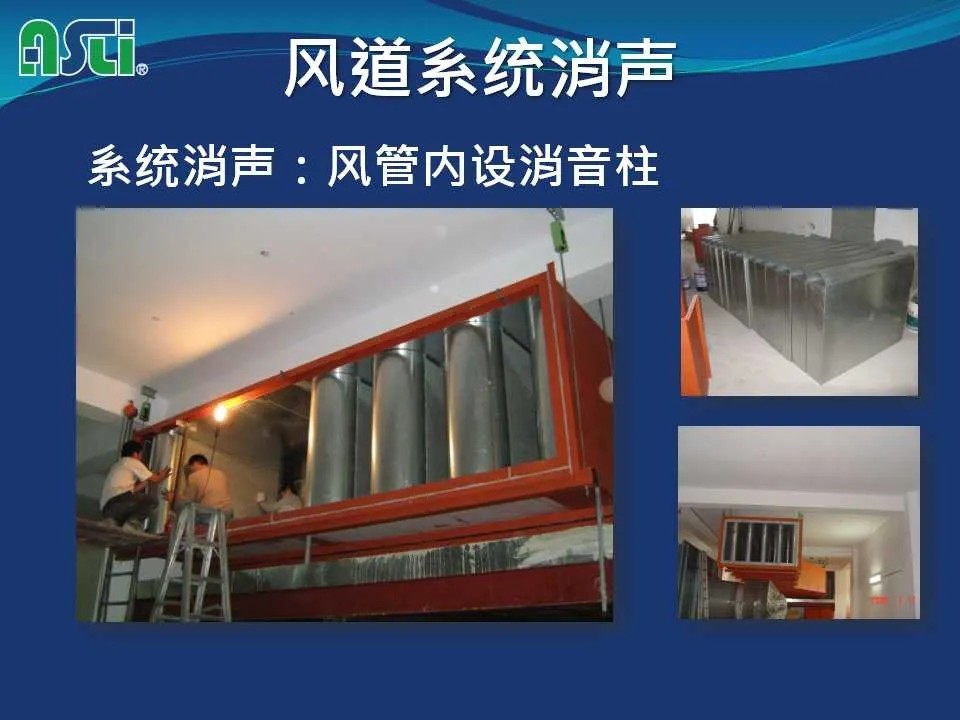

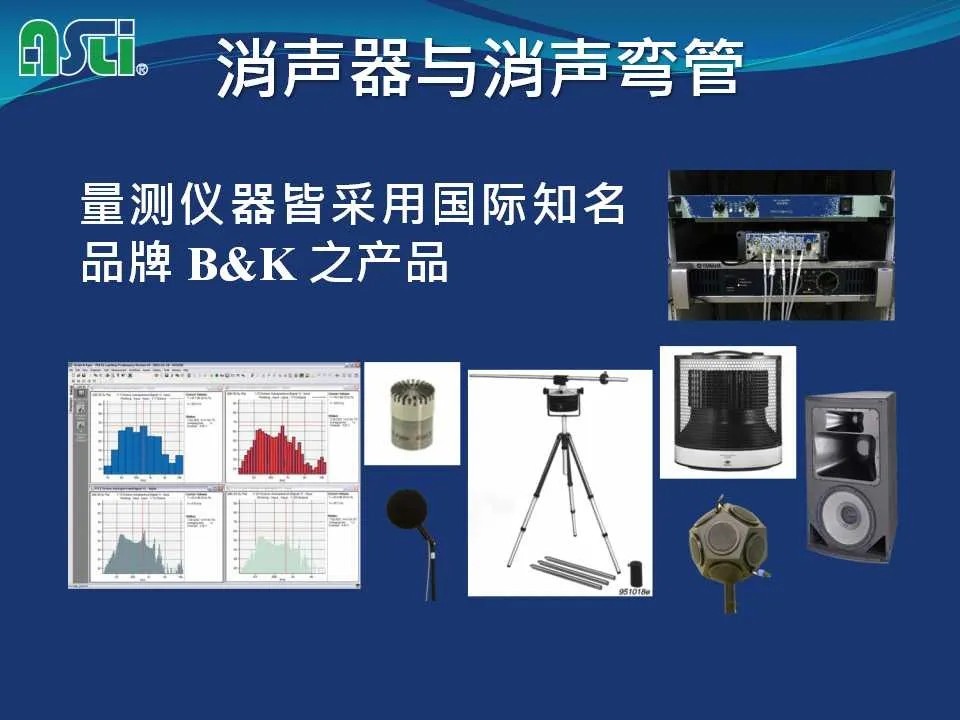

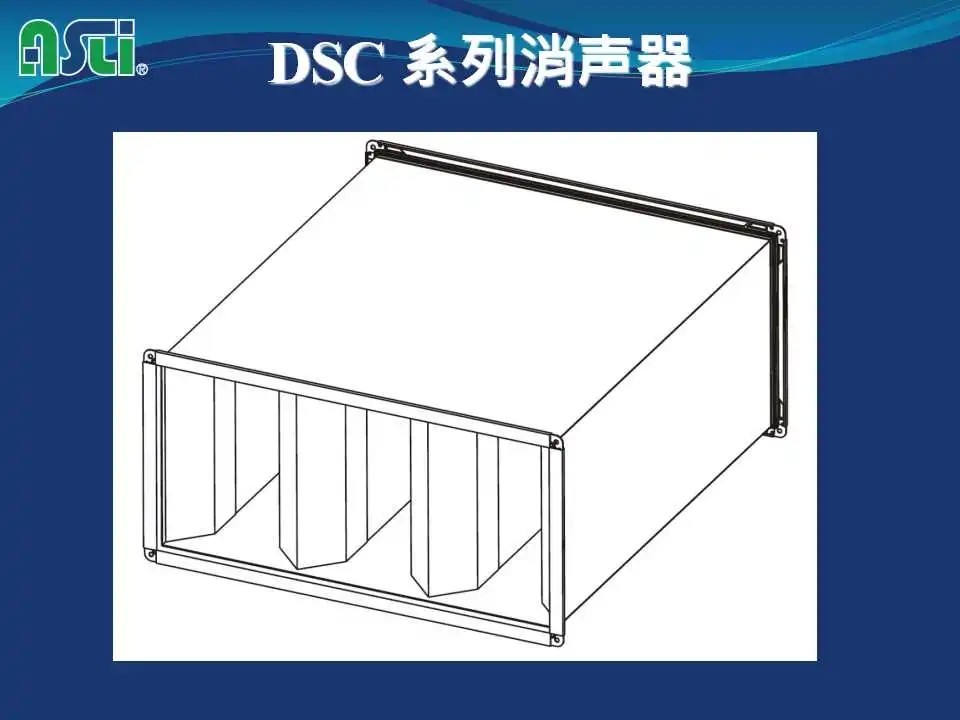

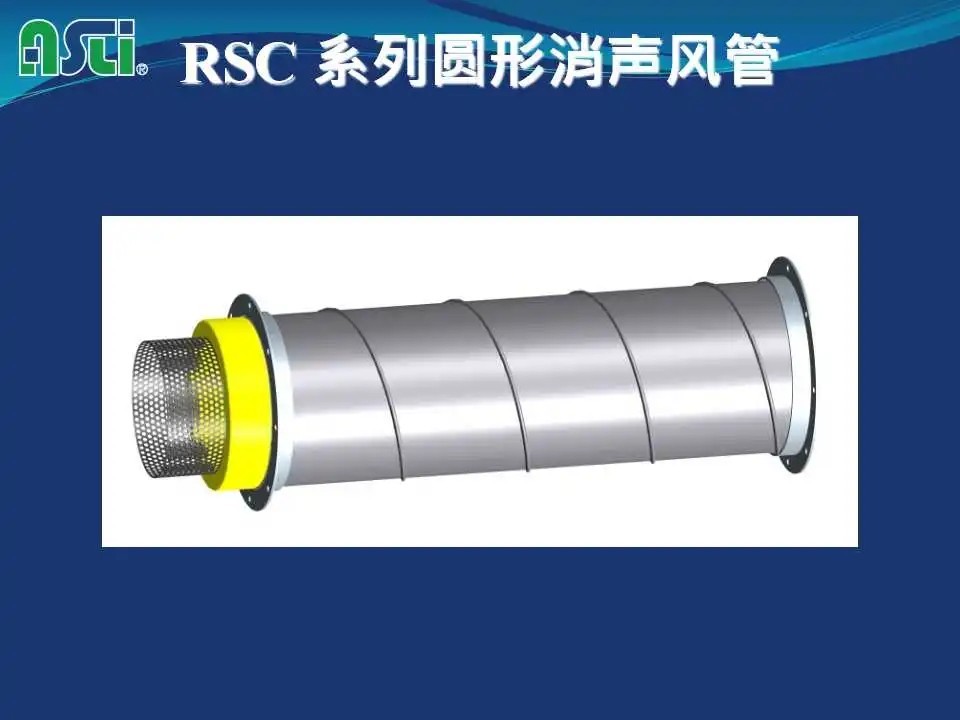

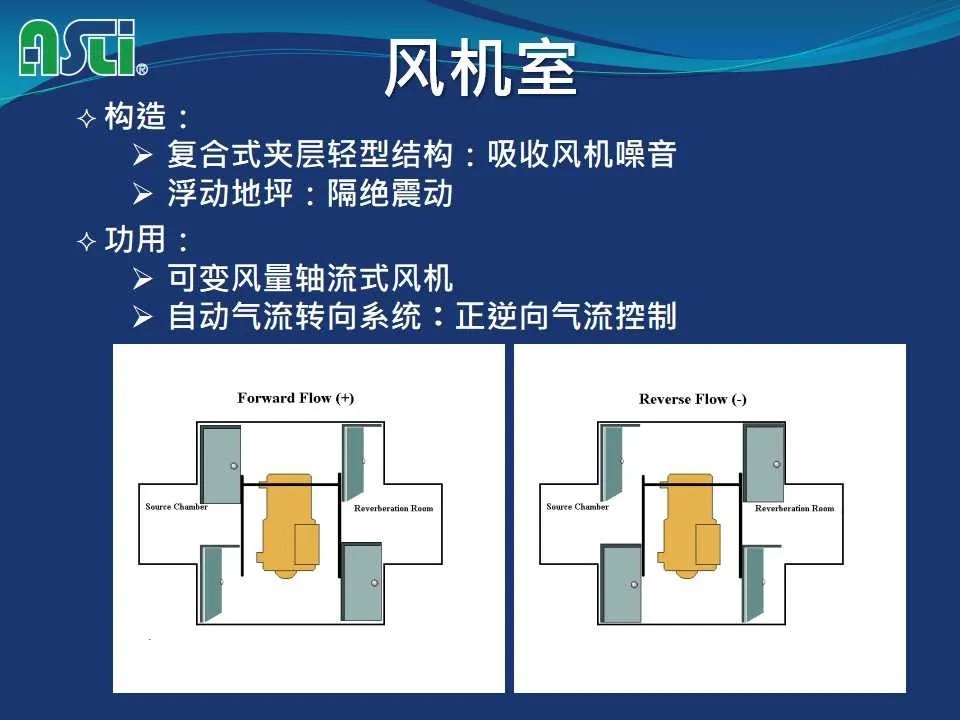

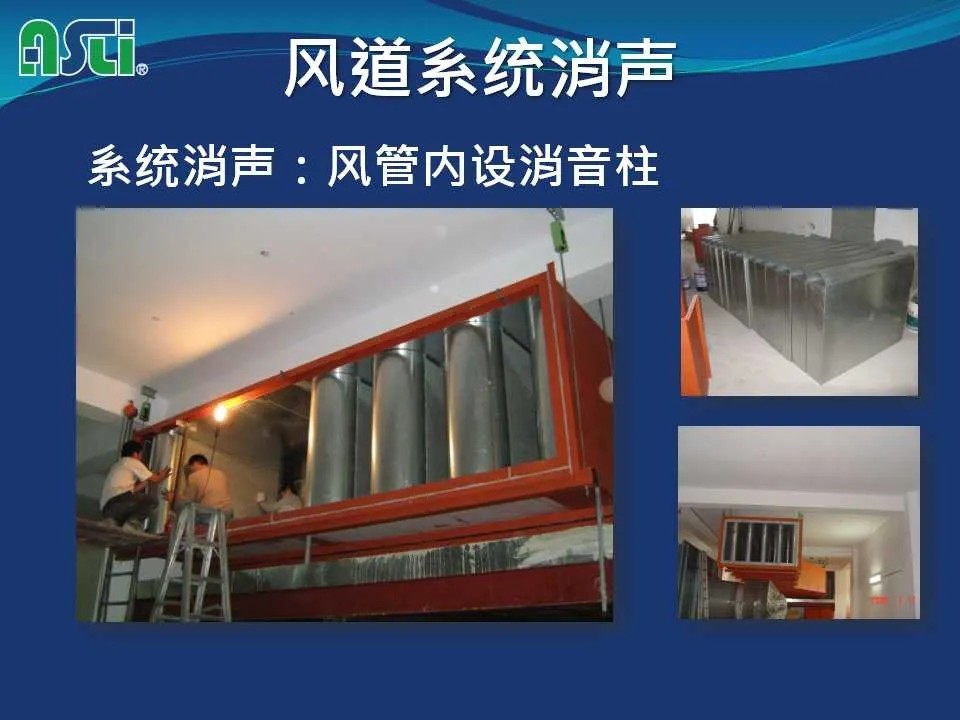

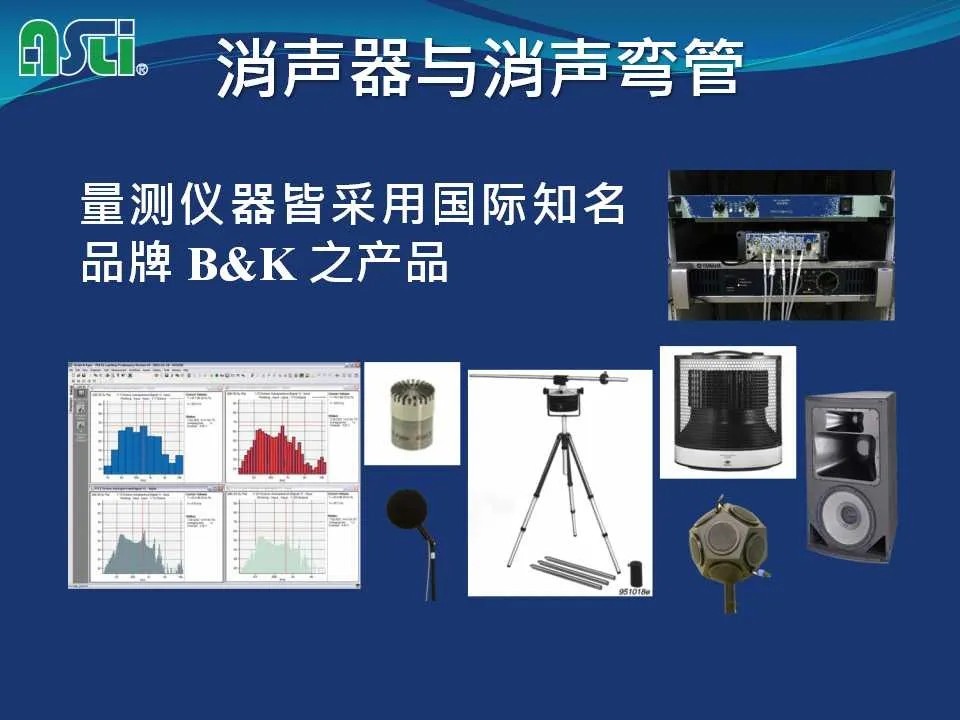

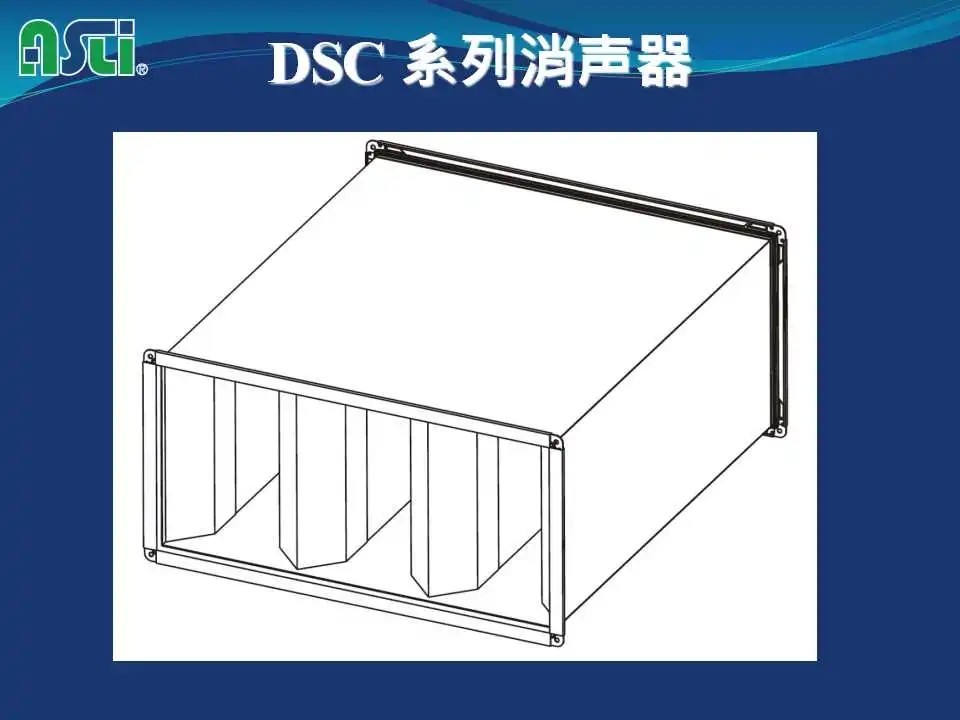

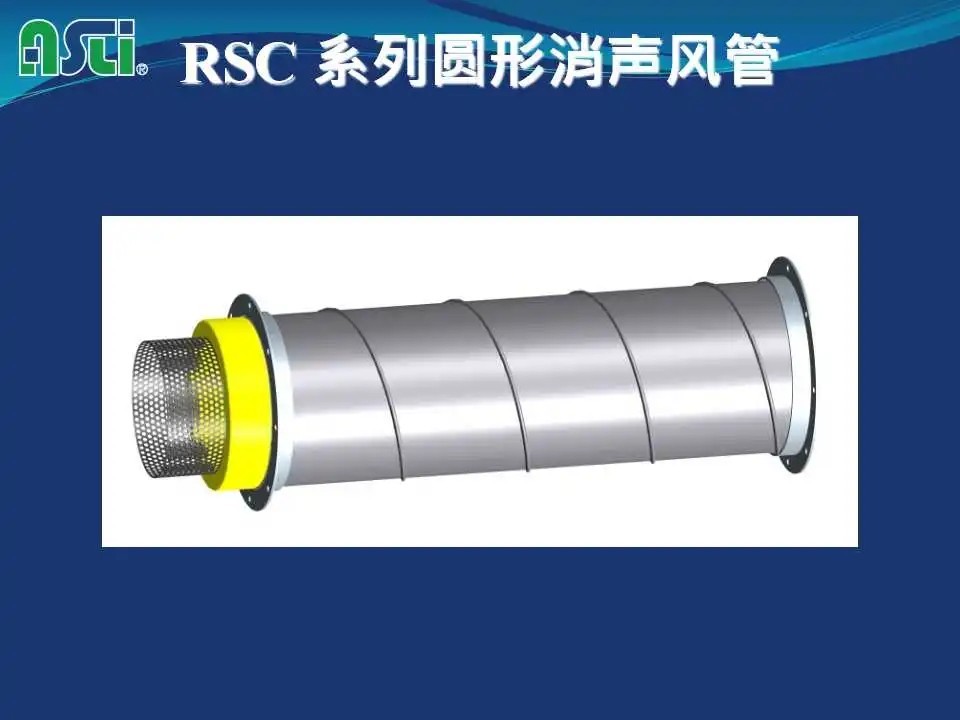

Muffler and muffler elbow performance test

量测方法

ASTM-E477 Standard Test Method for Measuring Acoustical and Airflow Performance ofDuct Liner Materials and Prefabricated Silencers

Measurement Items

√ Pressure Drop

√ Insertion Loss

√ Airflow Generated Noise

Measuring range

√ Frequency range -50Hz~8000Hz

√ Maximum wind speed -20m/s

Future work - Introducing national standard testing methods to meet the needs of the Chinese market

GB/T 25516 Acoustics - Laboratory measurement methods for duct silencers and duct end units - Insertion loss, airflow noise and total pressure loss

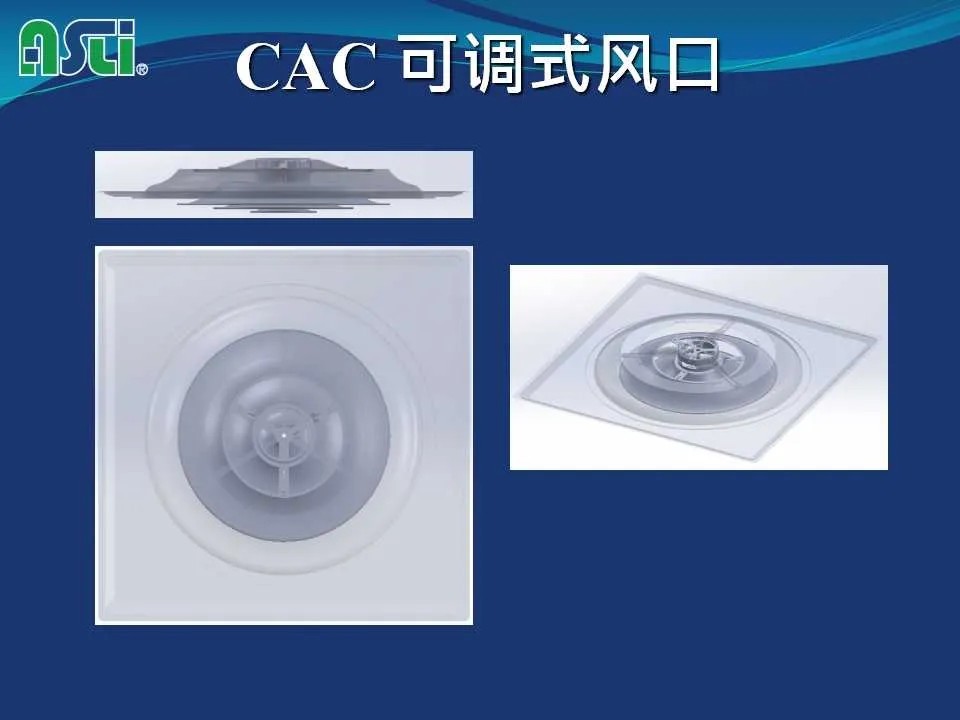

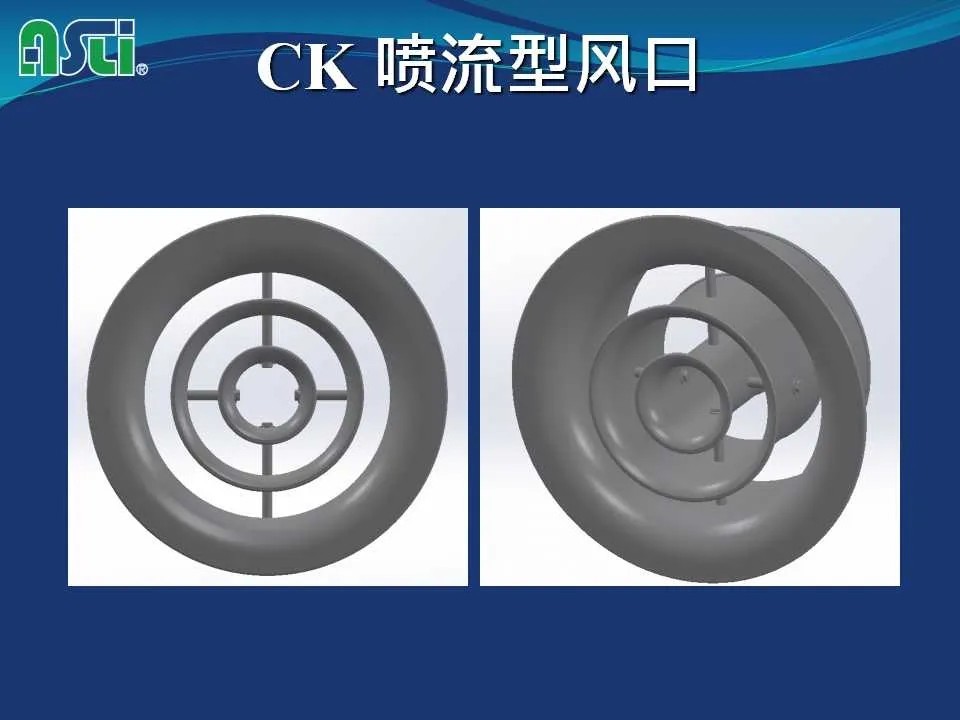

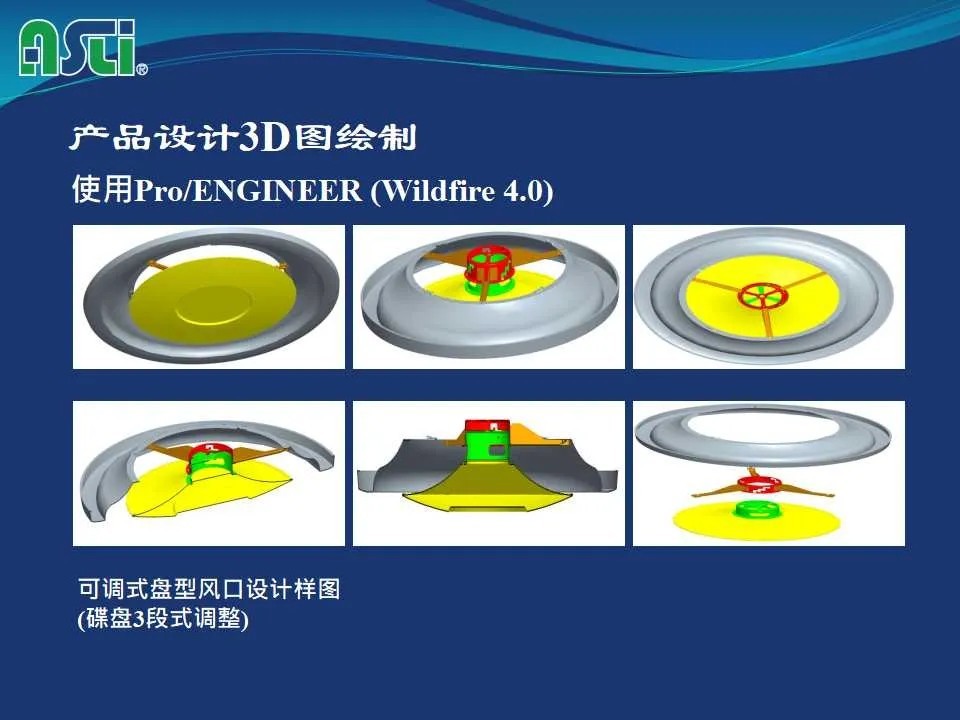

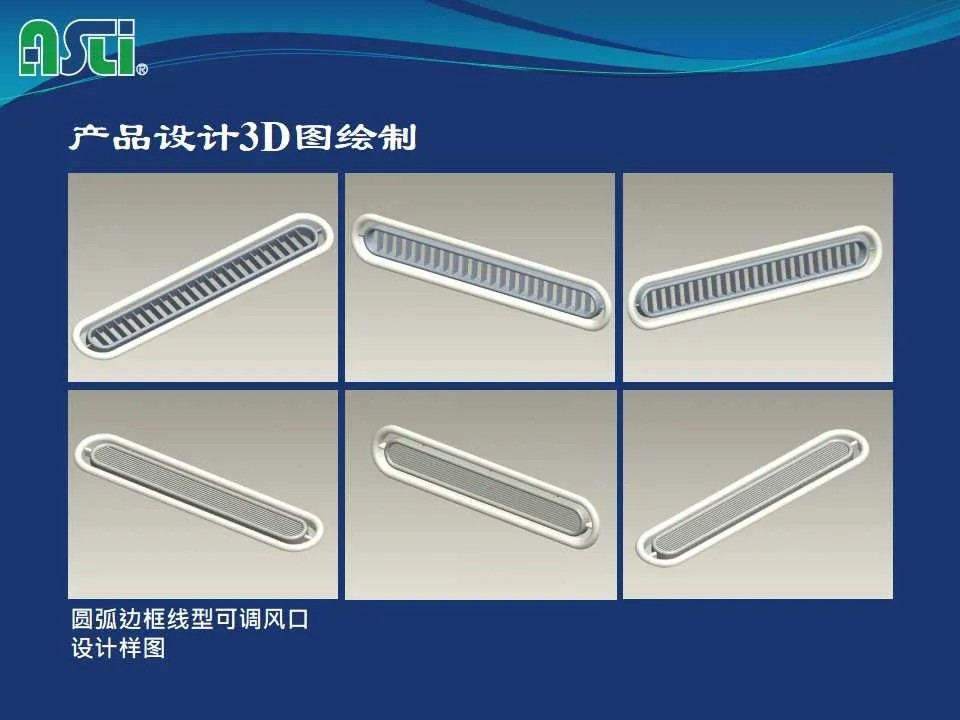

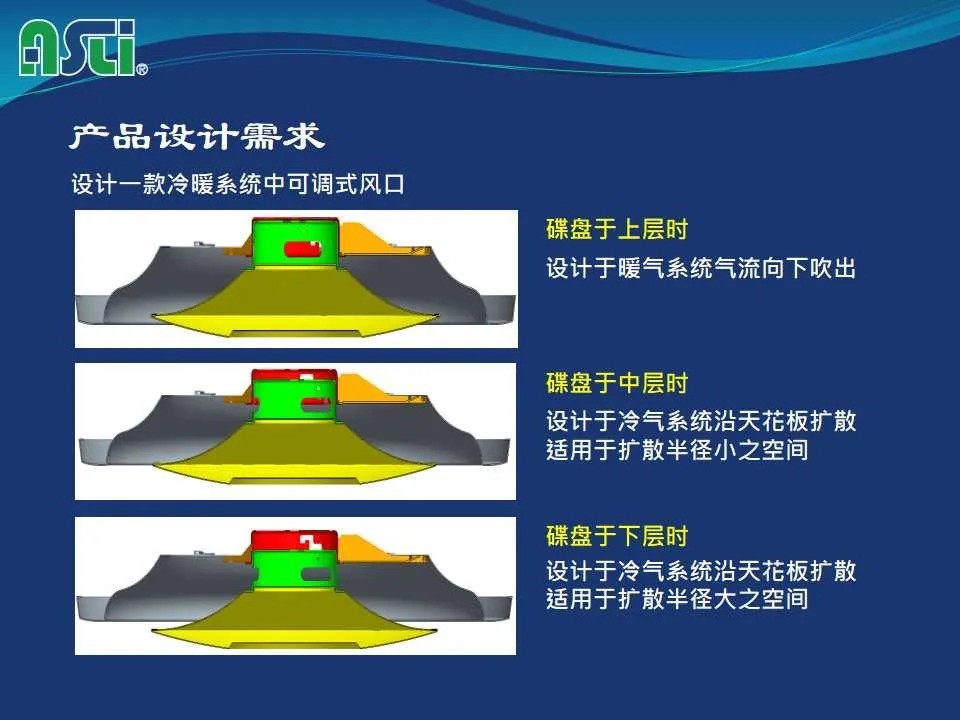

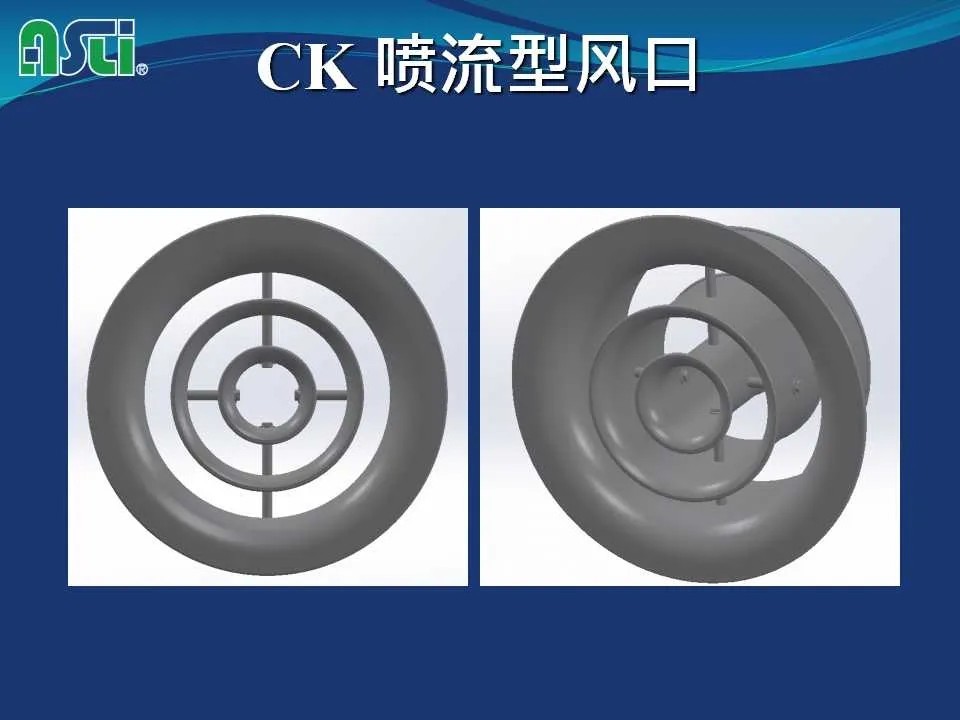

Product development and design

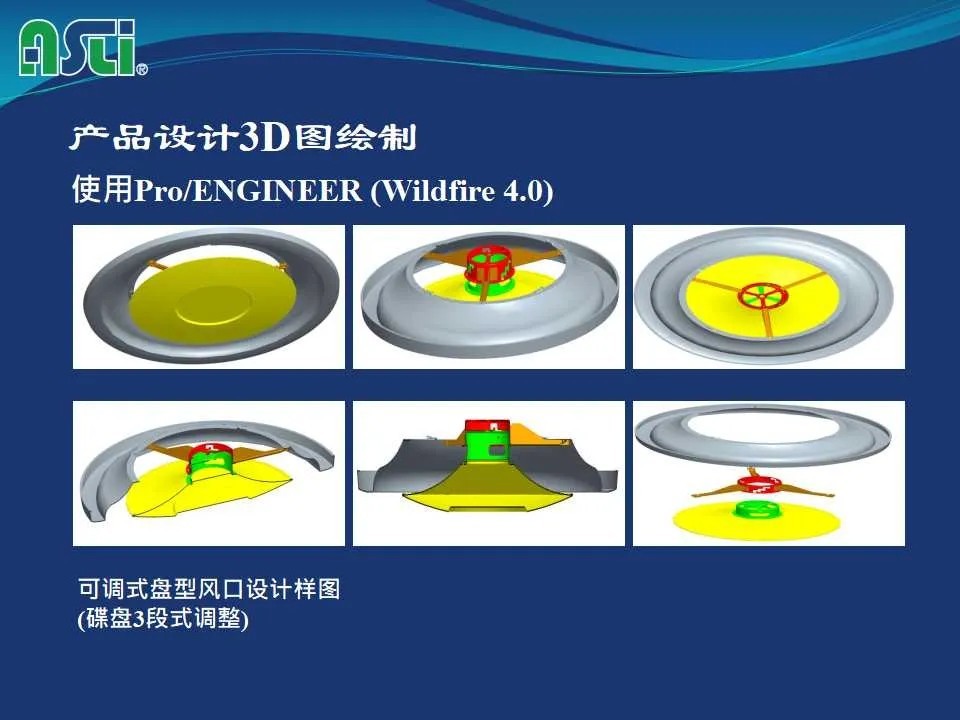

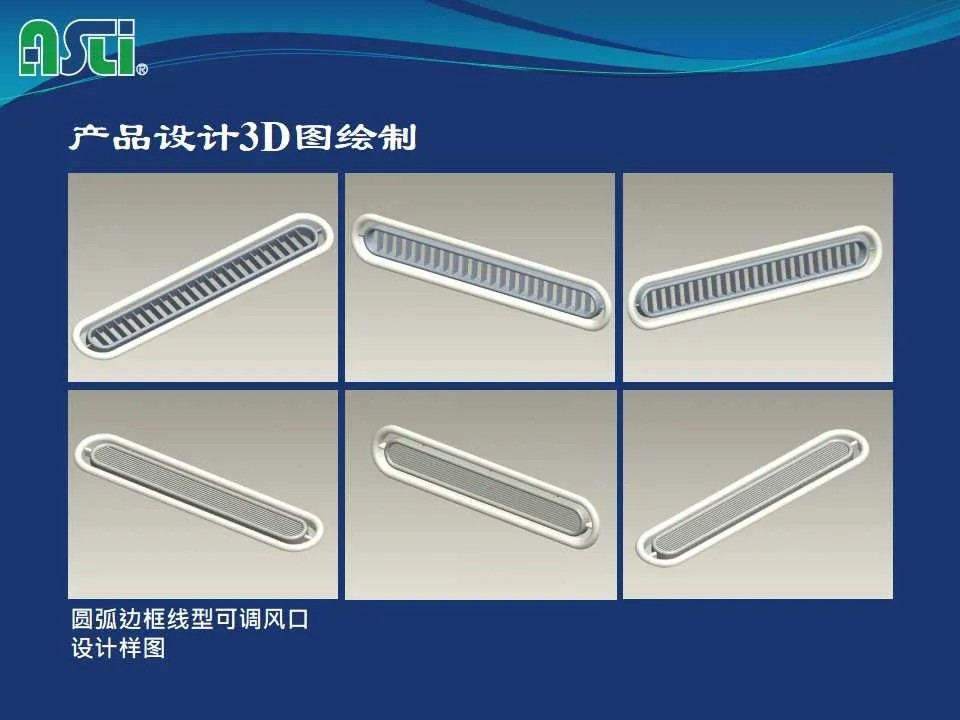

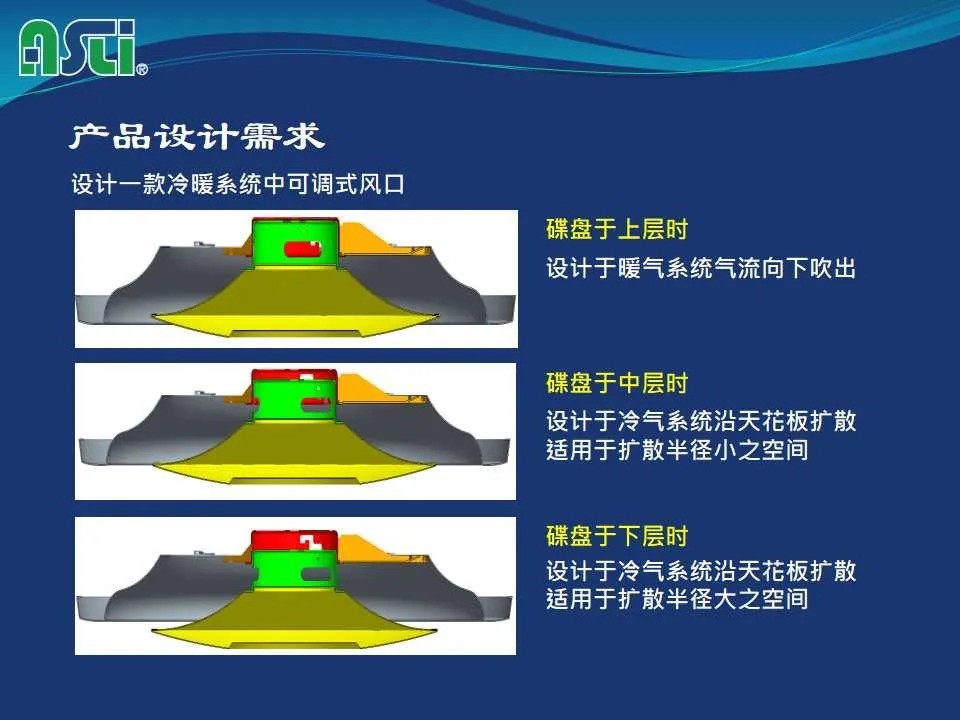

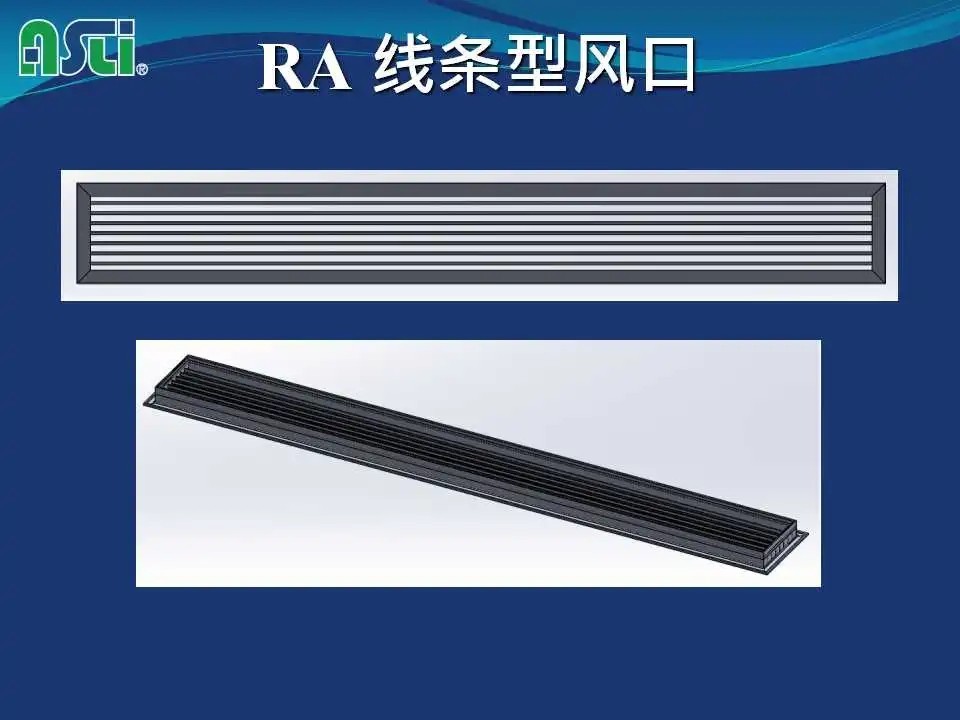

Product design 3D drawing

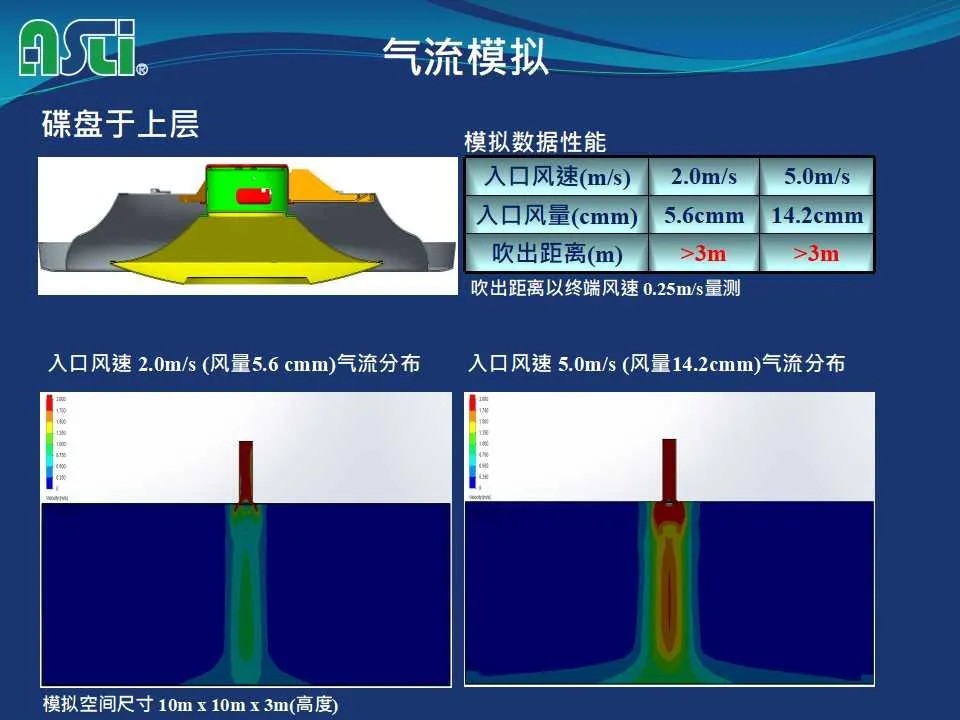

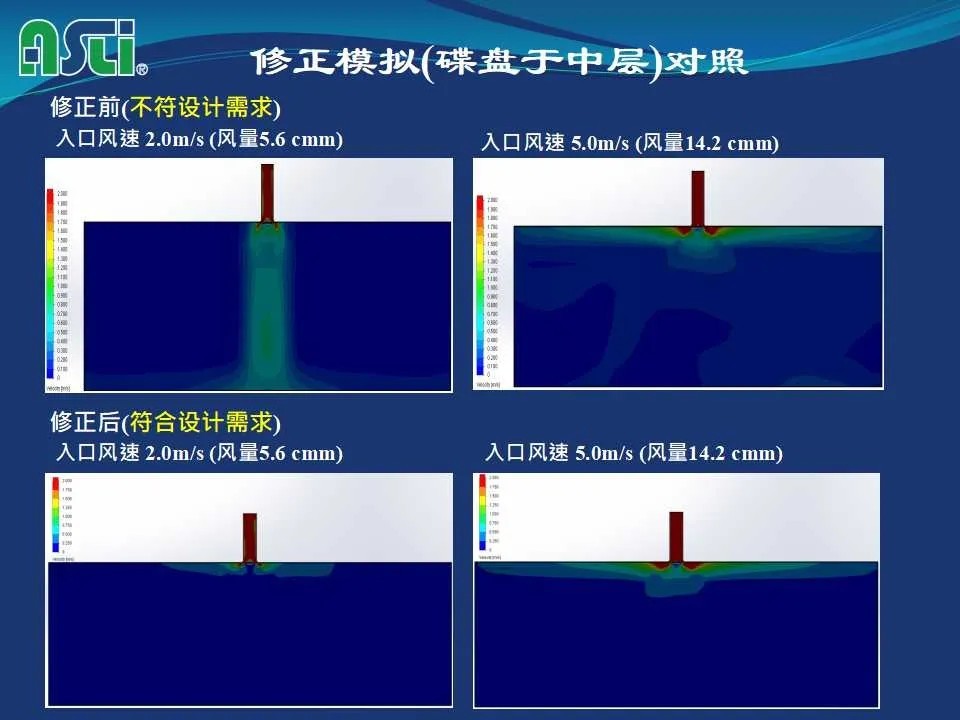

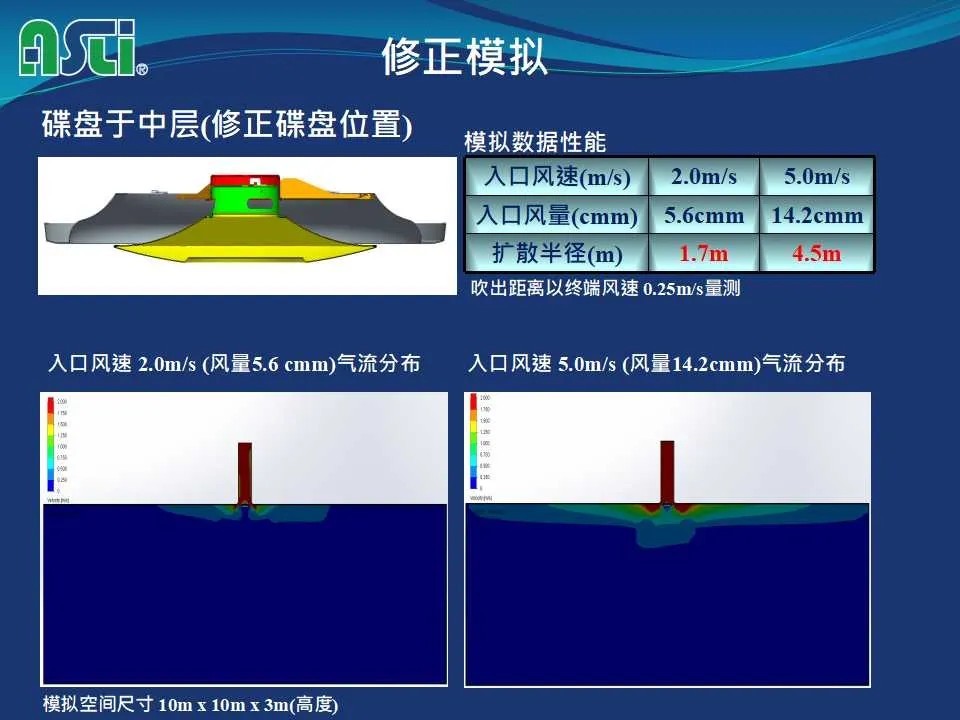

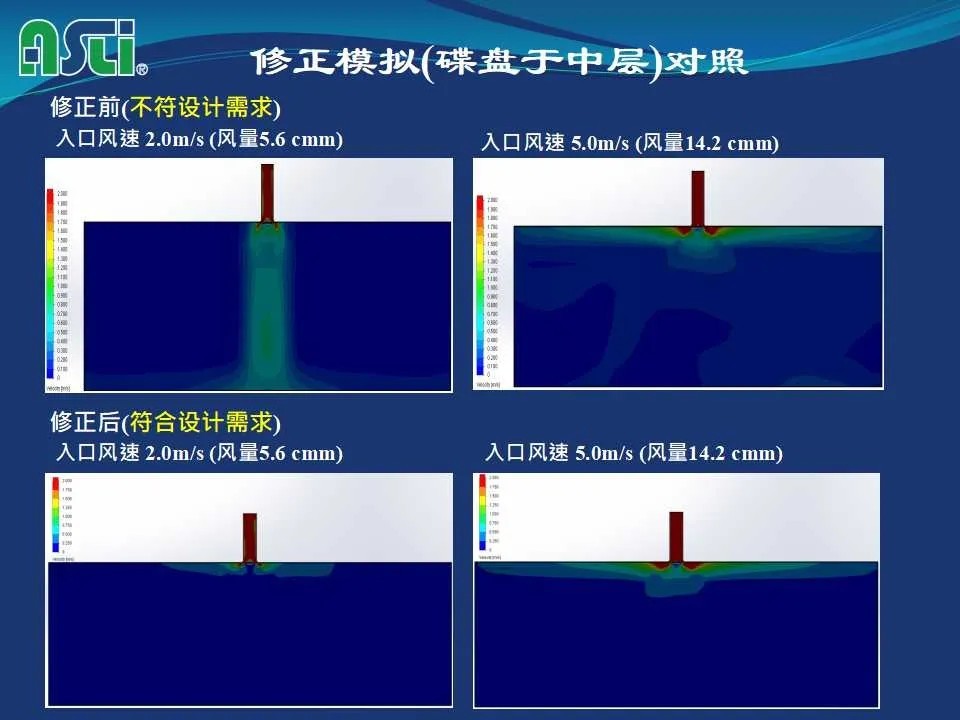

Product 3D computer airflow simulation

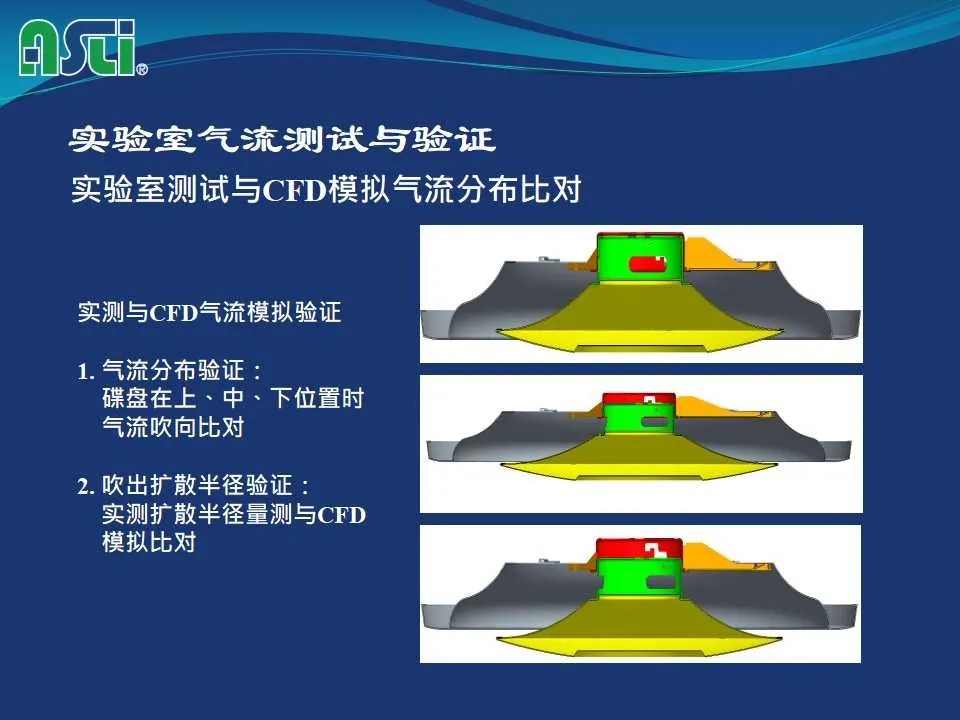

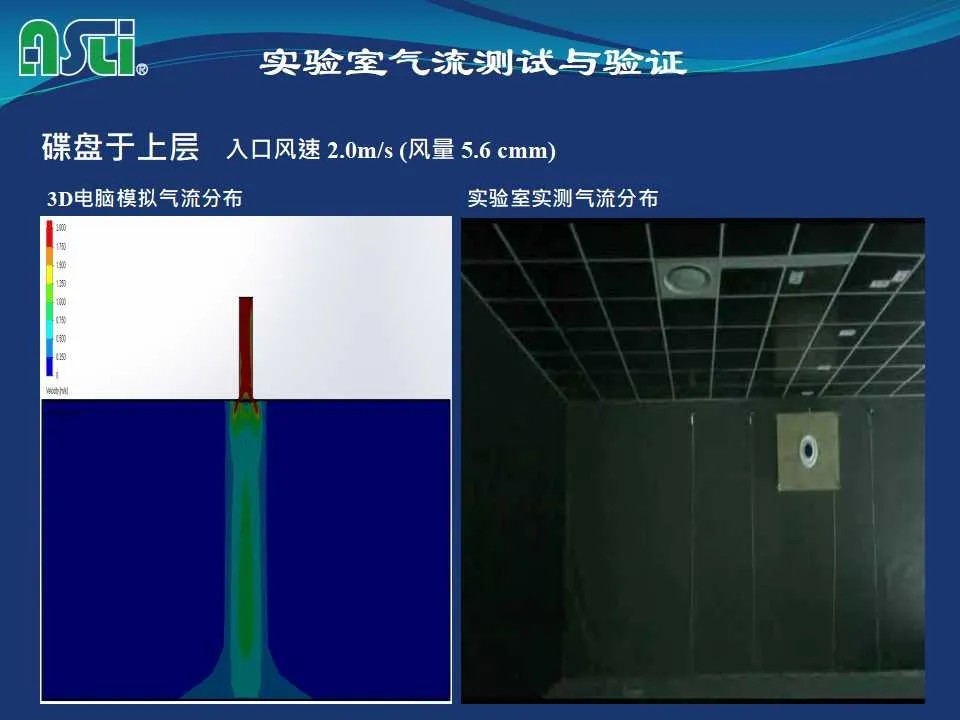

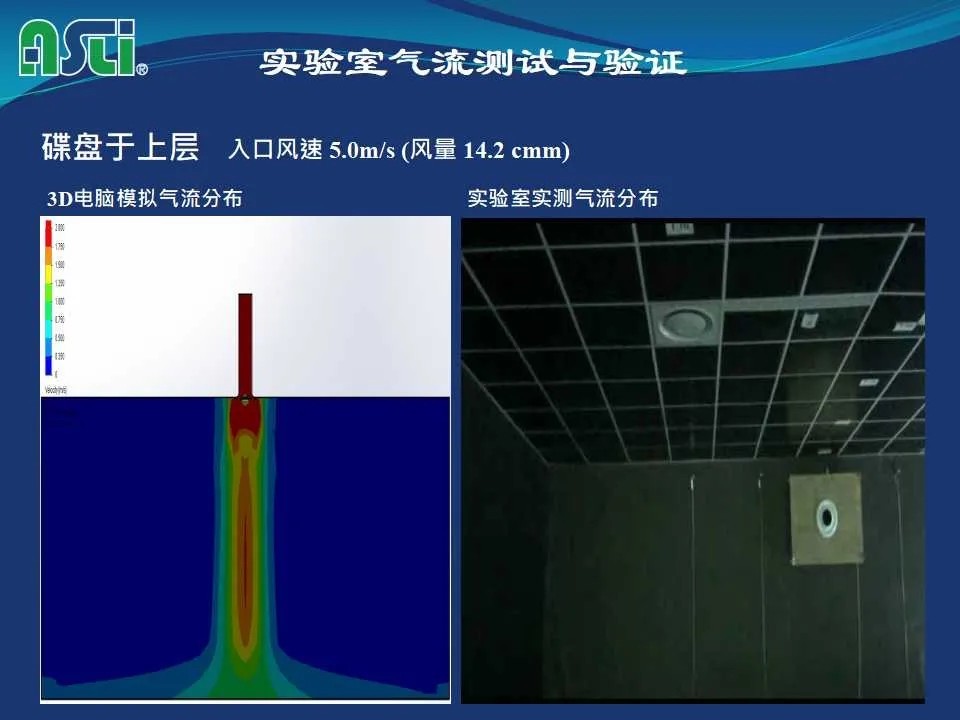

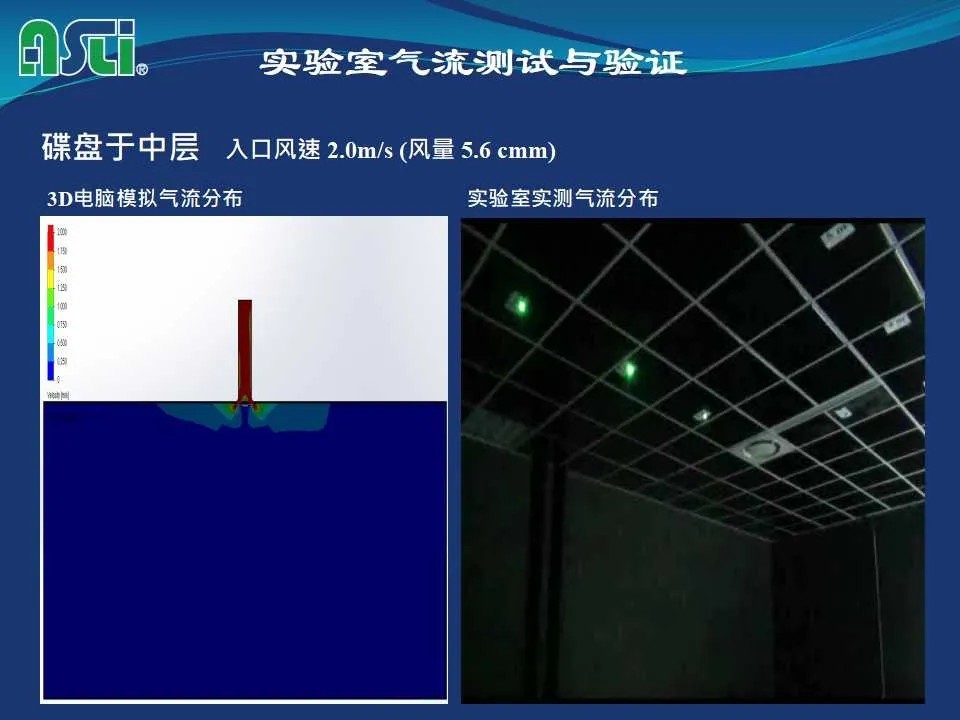

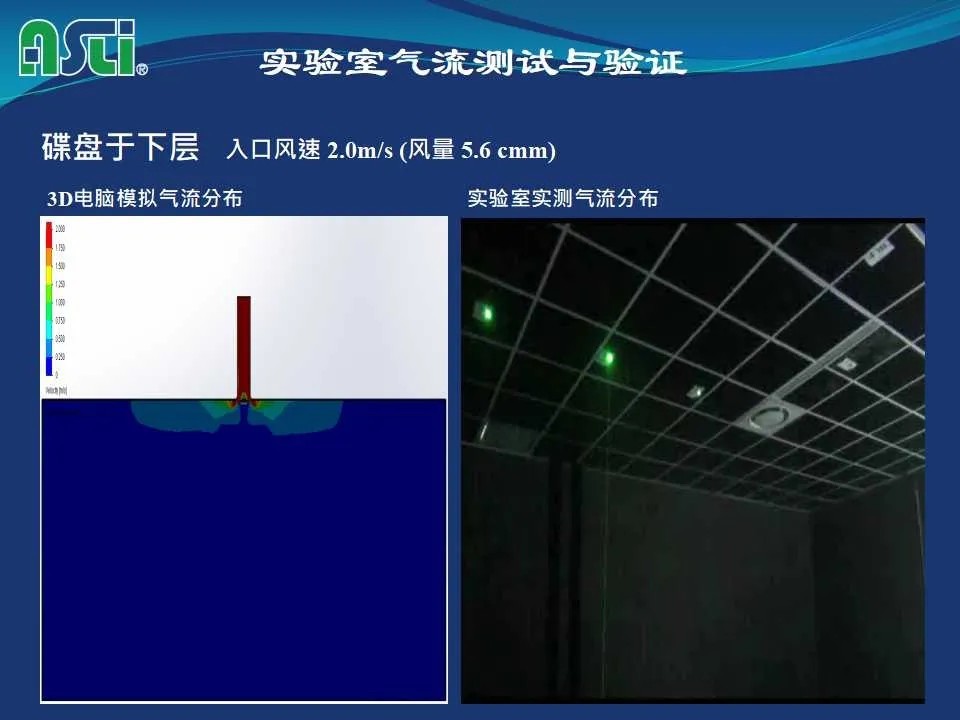

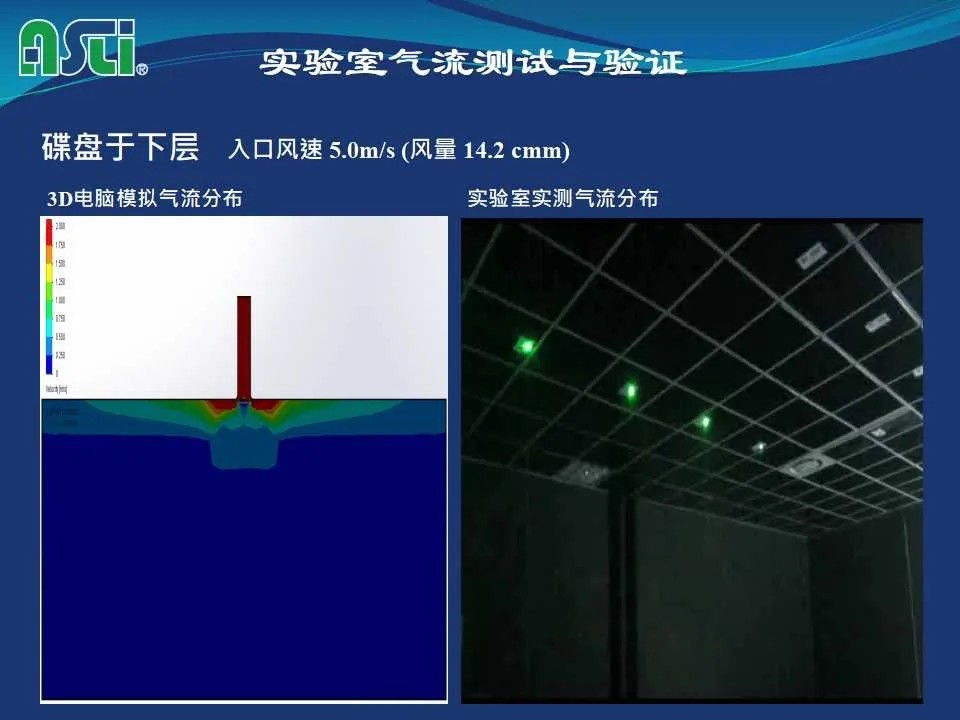

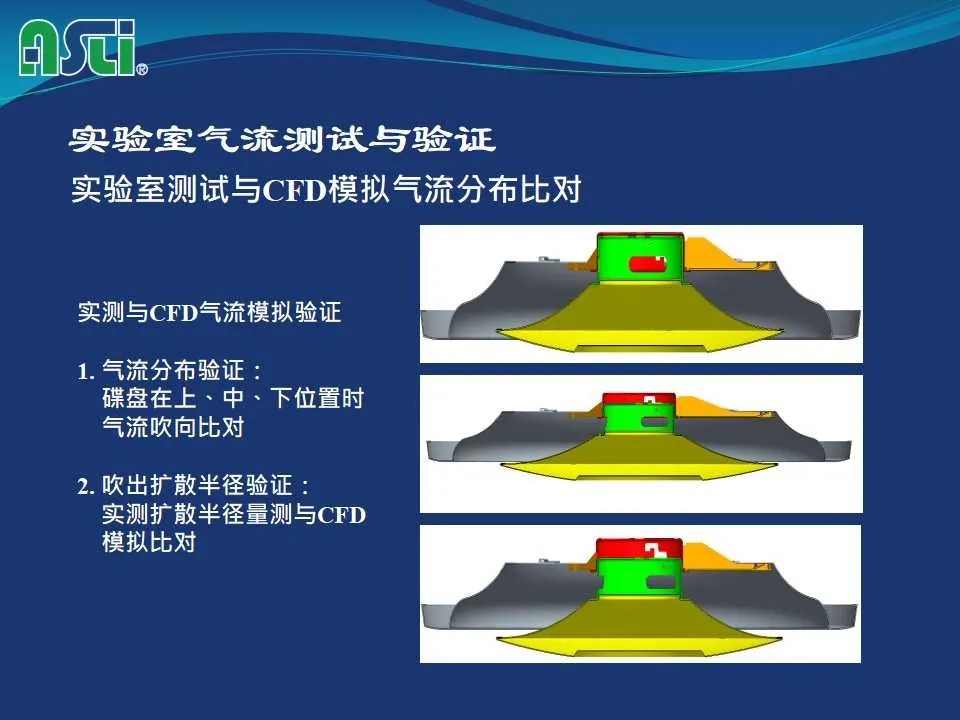

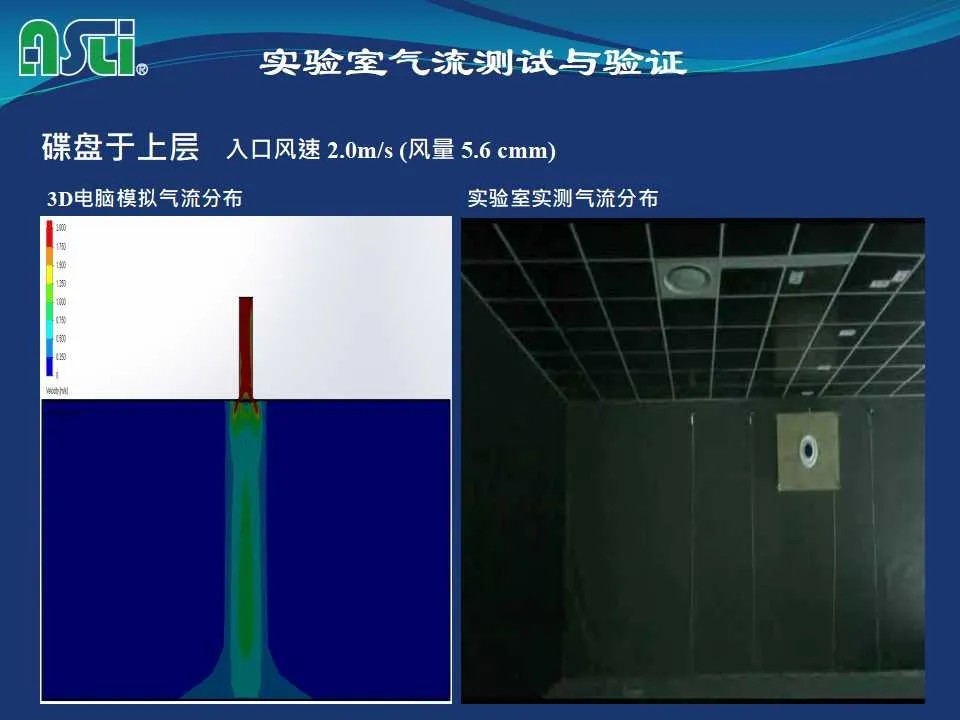

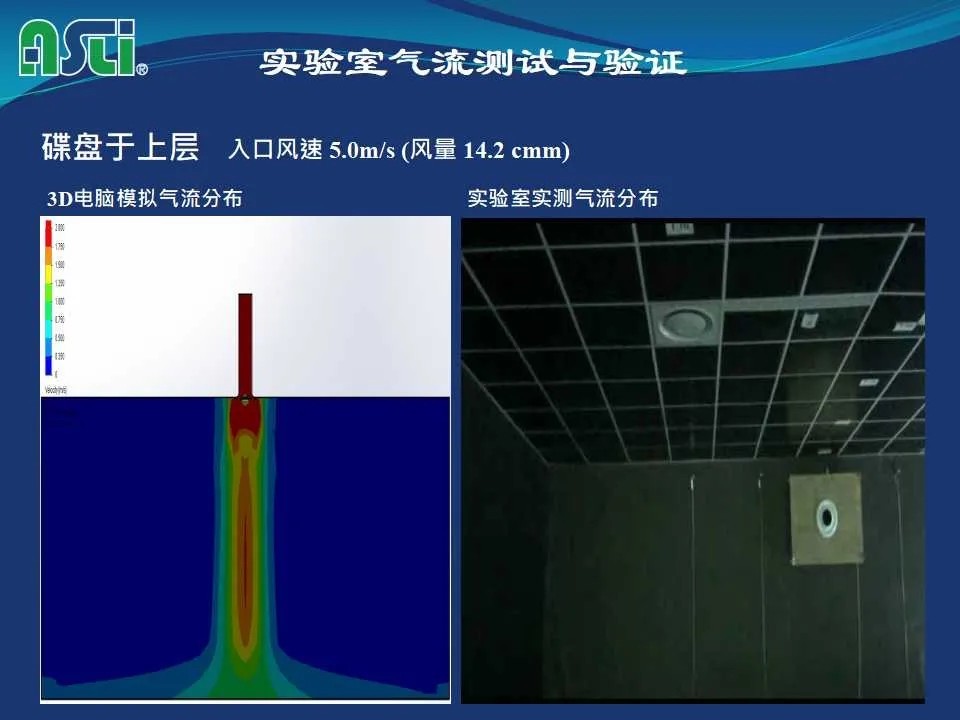

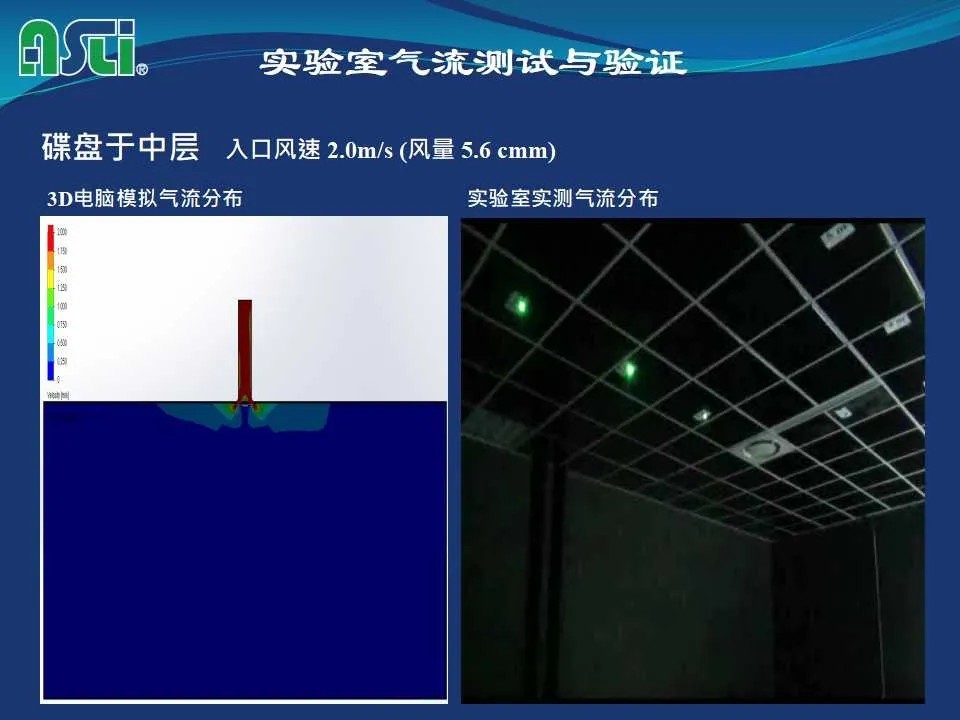

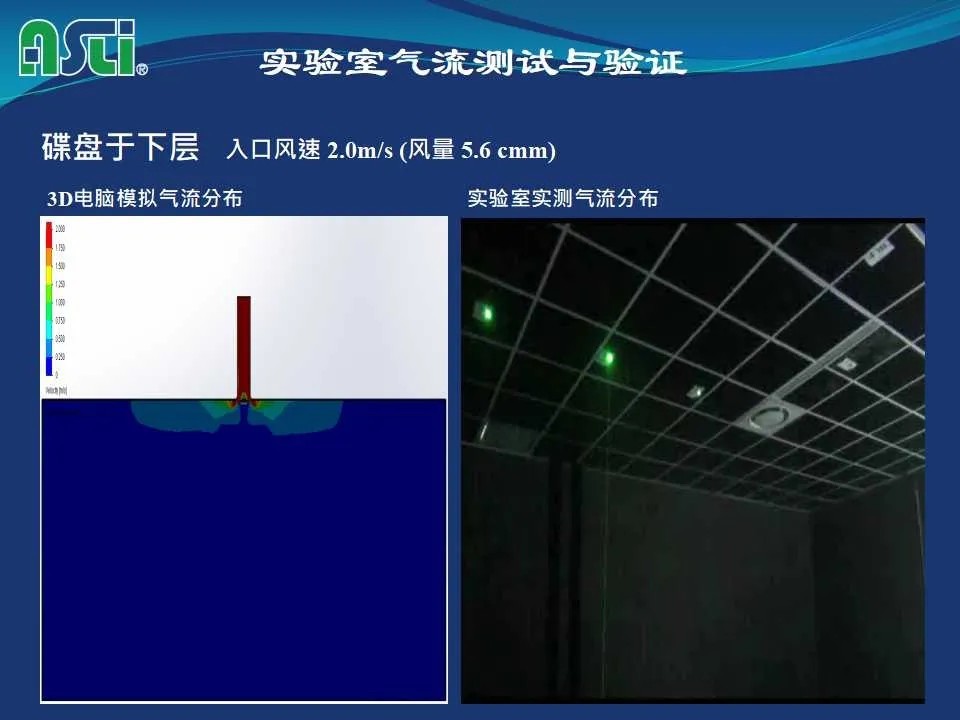

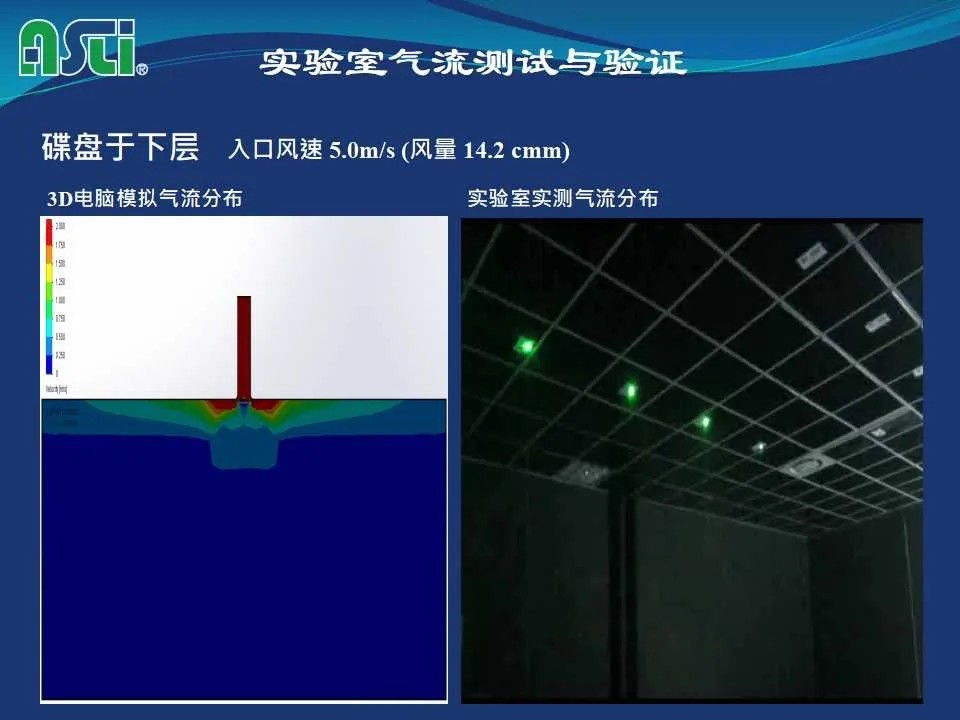

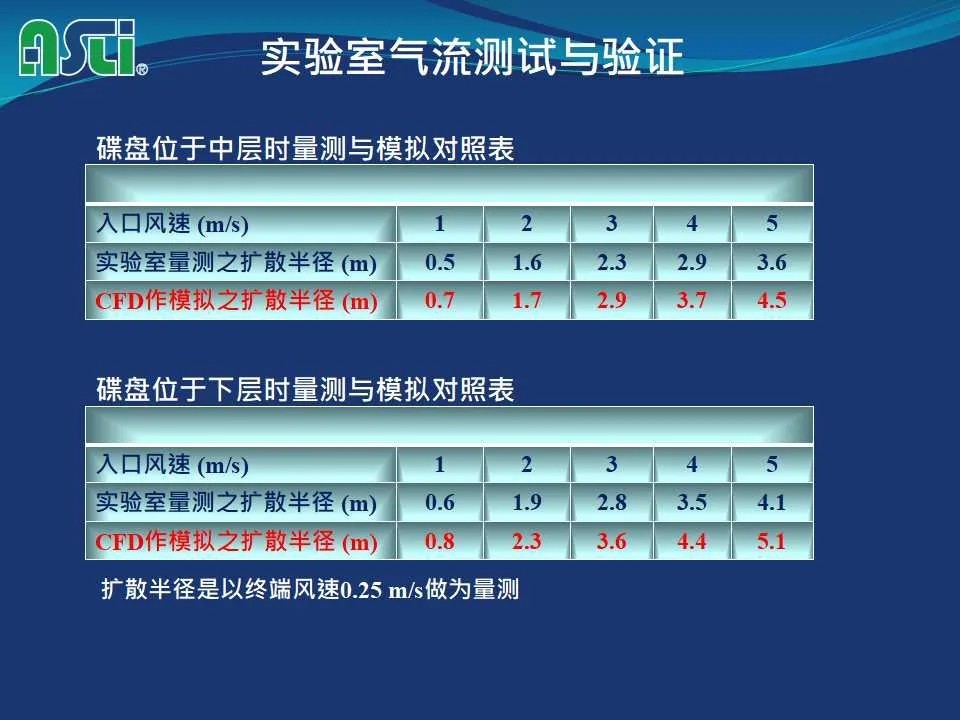

Laboratory Airflow Testing and Validation

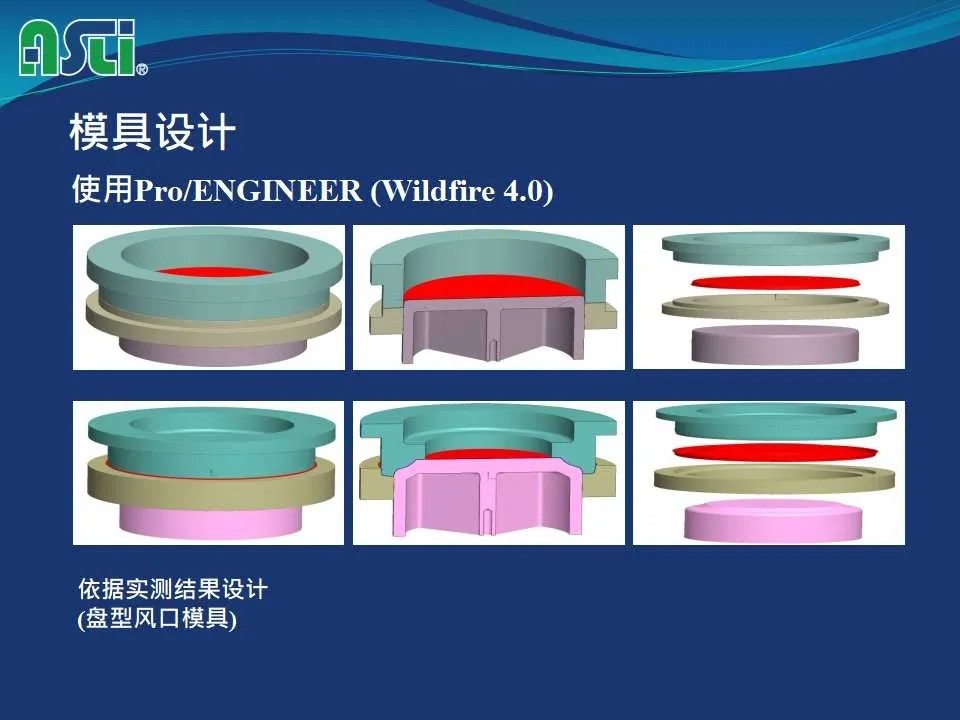

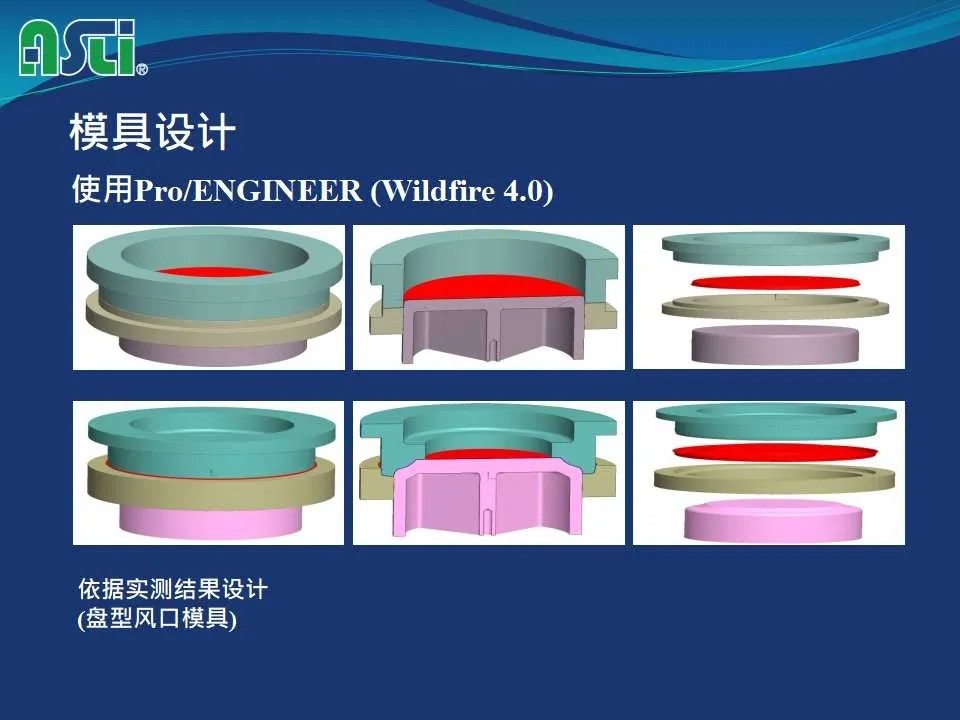

Mold design

Product performance testing

Air valve product performance test

Noise reduction product performance test

Headquarters Laboratory

Motivation for building a ventilation and noise laboratory

1. Verify the airflow distribution of the vents and provide correct performance data

2. Test the level of valve leakage to improve product competitiveness with world-class manufacturers

3. Overcome the difficulties in obtaining UL certification and increase the speed of fire damper performance verification

4. Provide noise product performance to improve the noise quality environment

5. Improve the product quality and corporate image of the group company

Laboratory Introduction

● The laboratory is located in Taoyuan, Taiwan, with a usable area of 2,600 square meters.

● In line with the market requirements of Taiwan and Southeast Asia, the measuring equipment

is designed and constructed in accordance with the test standards of ISO, AMCA, UL, ASTM and ASHRAE.

● Product performance verification test procedures and equipment and instruments all comply with relevant international test standards.

● Laboratory certification

A. Taiwan TAF Certification Foundation Certified Laboratory (SO 17025), certification number 2385. (TAF is equivalent to China CNAS)

B. US UL Certified Laboratory (UL 555/555S)

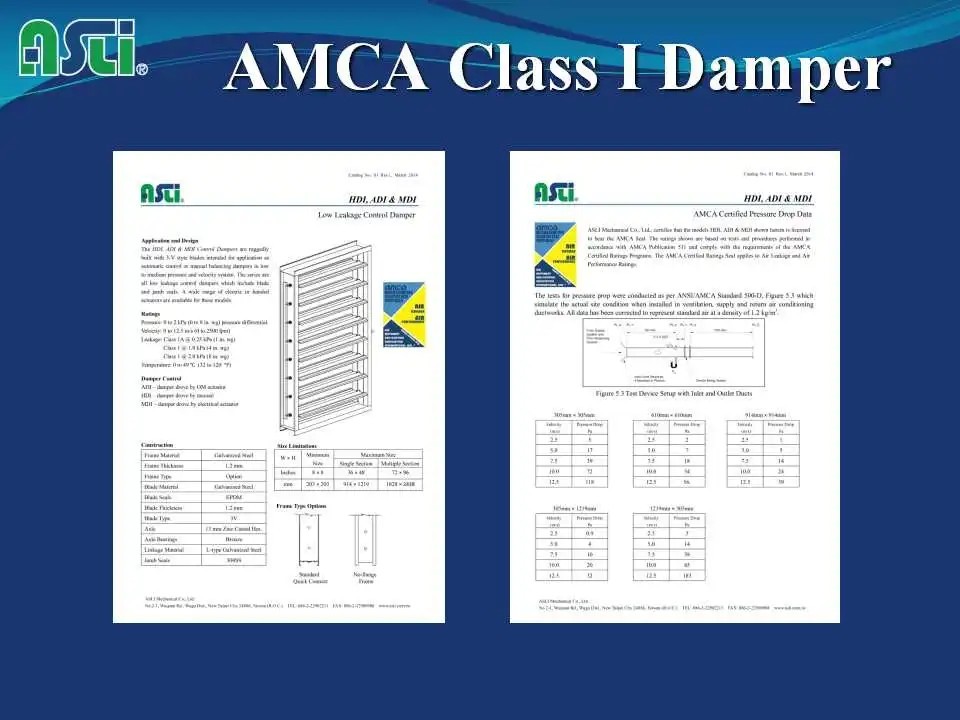

General air valve performance test

● Method basis: AMCA 500-D

● Equipment capabilities:

1. Circular air chamber

test port size - 1.14m Φ 1.14m

Maximum test pressure - 300mmAq

Maximum test air volume - 350CMM

2. Rectangular air chamber

test port size - 2.0m Φ 2.0m

Maximum test pressure - 340mmAq

Maximum test air volume - 2800CMM

● Measurement items: pressure loss, leakage and pressure resistance

Future work - Introducing national standard testing methods to meet the needs of the Chinese market

JG/T 436 Building ventilation air volume regulating valve

Fire valve performance test

Fire damper classification

● Smoke damper

● Fire damper

● Fire/smoke damper

Test Methods

● UL 555 -Fire Damper

● UL555S-Smoke Damper

● AMCA 500-D

Future work - Introducing national standard testing methods to meet the needs of the Chinese market

GB 15930 Fire dampers for building ventilation and smoke exhaust systems

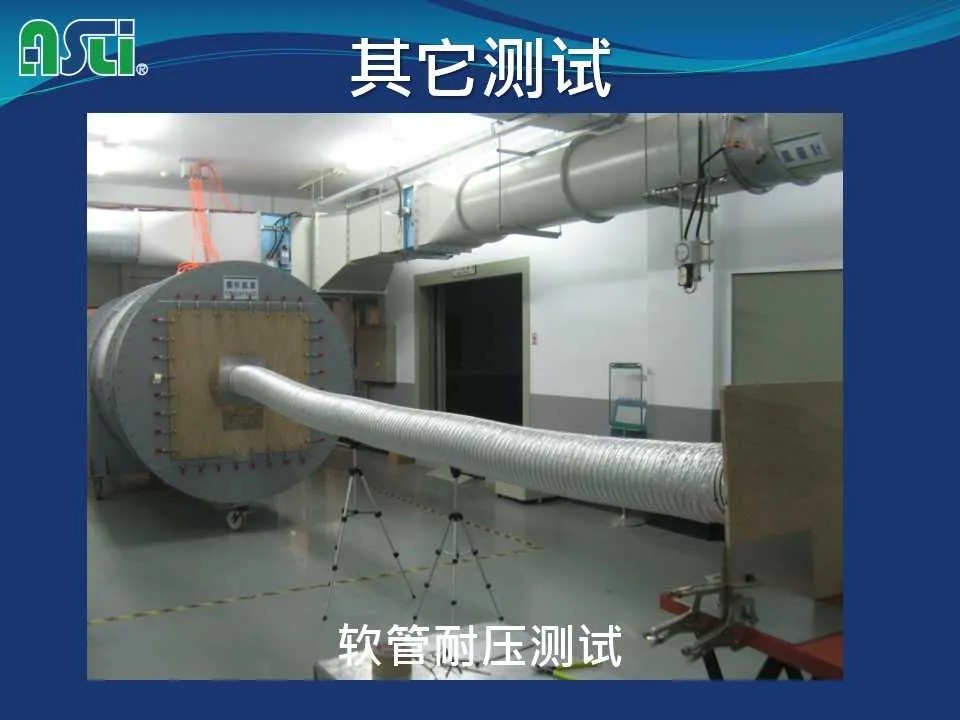

Various air outlet performance tests

● Method - ANSI-ASHRAE 70 Method of Testing the Performance of Air Outlets and Air Inlets

● Measurement items - Blowing distance (or diffusion radius), pressure loss

Future work - Introducing national standard testing methods to meet the needs of the Chinese market

1. JG/T 14 Ventilation and air conditioning vents

2. JG/T 20 Air distributor performance test method

Muffler and muffler elbow performance test

量测方法

ASTM-E477 Standard Test Method for Measuring Acoustical and Airflow Performance ofDuct Liner Materials and Prefabricated Silencers

Measurement Items

√ Pressure Drop

√ Insertion Loss

√ Airflow Generated Noise

Measuring range

√ Frequency range -50Hz~8000Hz

√ Maximum wind speed -20m/s

Future work - Introducing national standard testing methods to meet the needs of the Chinese market

GB/T 25516 Acoustics - Laboratory measurement methods for duct silencers and duct end units - Insertion loss, airflow noise and total pressure loss

Product development and design

Product design 3D drawing

Product 3D computer airflow simulation

Laboratory Airflow Testing and Validation

Mold design

Product performance testing

Air valve product performance test

Noise reduction product performance test

dengbaogang2006@163.com

dengbaogang2006@163.com +86 13901335544

+86 13901335544